Pleated Filter Element

Pleated filter elements are integral to various industries. They are key components in filtration systems, known for their efficiency and durability. This article explores the details of pleated filter elements, their applications, benefits, and cleaning methods.

What is a Pleated Filter Element?

A pleated filter element consists of a filter medium folded into pleats. This design increases the surface area without increasing the physical size of the filter. The increased surface area allows for better filtration and longer service life. Pleated filters are made from various materials, including paper, polyester, and stainless steel mesh.

Key Components

- Filter Medium: The core material that captures particles.

- End Caps: Provide structural integrity and sealing.

- Core: Supports the filter medium and ensures even flow distribution.

- Pleats: Increase the surface area for filtration.

Types of Pleated Filter Elements

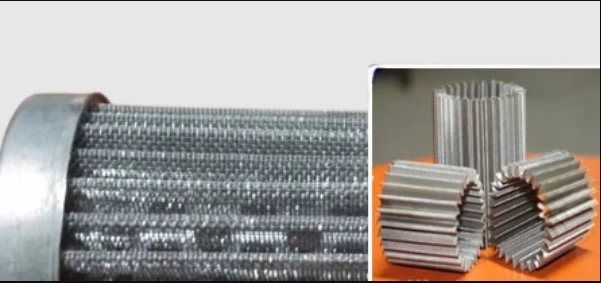

Mesh Pleated Filter Elements

Mesh pleated filter elements are used for high-precision filtration. These filters are made from stainless steel or other metal meshes, providing durability and reusability.

Pleated Filter Cartridges

Pleated filter cartridges are versatile. They are used in dust collectors, liquid filtration, and air filtration. The pleated design allows for high dirt-holding capacity and low-pressure drop.

Star-Pleated Filter Elements

Star-pleated filter elements are designed for high-flow applications. They offer a larger filtration surface area and are ideal for systems requiring high flow rates and low-pressure drops.

Pleated Metal Filters for Filter Candle Screen Changers

These filters are used in polymer melt filtration processes. They can withstand high pressures and temperatures, making them suitable for demanding applications.

Applications of Pleated Filter Elements

Cartridge Filter Systems

Pleated filter elements are integral to cartridge filter systems. These systems are used in various industries, including water treatment, food and beverage, pharmaceuticals, and oil filtration. The pleated design ensures efficient removal of contaminants and extends the service life of the filter.

Oil Filter Filtration

In the oil and gas industry, pleated filter elements are crucial. They are used in the filtration of hydraulic fluids, lubricants, and fuels. These filters ensure the removal of contaminants, preventing damage to machinery and improving performance.

Air Filtration

Pleated air filter elements are used in HVAC systems. They help in maintaining indoor air quality by trapping dust, pollen, and other airborne particles.

Liquid Filtration

Pleated filter cartridges are used for liquid filtration in various industries. They provide efficient filtration of water, chemicals, and other liquids, ensuring purity and protecting downstream equipment.

Dust Collection

Pleated filter cartridges are also used in dust collection systems. They trap dust particles, ensuring a clean and safe working environment.

Compressor Filter Elements

Compressor filter elements are designed to remove contaminants from compressed air systems. These filters ensure the delivery of clean air, which is essential for the proper functioning of pneumatic equipment.

Inner Oil Filters

Inner oil filters are used in various industrial applications. They help in removing impurities from oils and lubricants, ensuring the longevity and efficiency of machinery.

Advantages of Pleated Filter Elements

- High Filtration Efficiency: The pleated design increases the surface area, allowing for higher filtration efficiency.

- Longer Service Life: The increased surface area also means that the filter can hold more contaminants before needing replacement.

- Versatility: Pleated filters can be used in a wide range of applications, from air and liquid filtration to oil and gas filtration.

- Durability: Filters made from stainless steel mesh or other durable materials can withstand high pressures and temperatures.

- Cost-Effective: Due to their long service life and reusability, pleated filters are cost-effective in the long run.

How to Clean Pleated Filters

Regular cleaning of pleated filters is essential to maintain their efficiency and prolong their service life. Here are some common cleaning methods:

- Manual Cleaning: For lightly soiled filters, manual cleaning using water and mild detergent is effective. Gently rinse the filter and allow it to dry completely before reinstalling.

- Compressed Air: For dust and particulate matter, use compressed air to blow out the contaminants. Ensure to blow air in the opposite direction of the normal flow.

- Ultrasonic Cleaning: For heavily soiled filters, ultrasonic cleaning is recommended. This method uses ultrasonic waves to dislodge contaminants from the filter medium.

- Chemical Cleaning: For filters used in chemical processes, chemical cleaning agents can be used to dissolve and remove contaminants. Ensure to rinse thoroughly and dry the filter before use.

Choosing the Right Pleated Filter Cartridge Manufacturers in India

India has numerous manufacturers specializing in pleated filter cartridges. When selecting a manufacturer, consider the following:

- Quality Standards: Ensure the manufacturer complies with international quality standards.

- Customization: Look for manufacturers that offer customization to meet specific filtration requirements.

- After-Sales Support: Reliable after-sales support is crucial for maintenance and troubleshooting.

- Experience: Manufacturers with extensive experience in the industry are likely to provide better products and services.

Comparison of Pleated Filter Elements

| Filter Type | Material | Applications | Benefits |

|---|---|---|---|

| Mesh Pleated Filter Elements | Stainless Steel | High-precision filtration | Durable, Reusable |

| Pleated Filter Cartridges | Polyester, Paper | Dust Collection, Liquid Filtration | High dirt-holding capacity |

| Star-Pleated Filter Elements | Various Metals | High-flow applications | Larger filtration surface area |

| Pleated Metal Filters for Screen Changers | Stainless Steel | Polymer Melt Filtration | Withstand high pressures, Durable |

| Compressor Filter Elements | Various Metals | Compressed Air Systems | Ensure clean air delivery |

| Inner Oil Filters | Various Metals | Industrial Oil Filtration | Remove impurities, Prolong machinery life |

Custom Pleated Filter Elements from our Factory

Our factory specializes in custom pleated filter elements tailored to meet specific industrial needs. We offer a wide range of materials and designs to ensure optimal filtration performance. Each filter is manufactured with precision, ensuring durability and efficiency. Our custom pleated filters are ideal for various applications, including liquid filtration, air purification, and dust collection. We provide solutions that enhance filtration efficiency and reduce maintenance costs. Trust our expertise to deliver high-quality, reliable filters that meet your unique requirements.