Custom Sintered Metal Filters

Sintered metal filters are a cutting-edge solution for efficient filtration across various industries. They are created by sintering metal powders at high temperatures to form a porous structure, which combines durability and high filtration efficiency.

What are Sintered Metal Filters?

Sintered metal filters are created through a process where metal powders are heated below their melting points until the particles bond. This process produces a solid, porous structure that is durable and efficient for filtration. These filters are widely used due to their strength, reusability, and chemical resistance, making them suitable for demanding industrial applications.

For more information about Sintering, please read here.

History of Sintered Metal Filters

The development of sintered metal filters dates back to the early 20th century when the need for durable and efficient filtration solutions became apparent in industrial processes. Initially used in high-temperature and high-pressure environments, these filters have evolved with advancements in materials science and manufacturing technologies. Today, they are an integral part of various industries, providing reliable filtration for a wide range of applications.

Key Benefits

Durability and Strength

These filters are known for their ability to withstand high temperatures and pressures, making them ideal for demanding environments. Their robust structure ensures long-term reliability.

Reusability

One significant advantage of sintered metal filters is their reusability. They can be cleaned and reused multiple times, reducing the cost and need for frequent replacements.

Chemical Resistance

Sintered metal filters are highly resistant to a wide range of chemicals, ensuring their effectiveness in various applications, from industrial processes to food and beverage production.

Applications

Industrial Filtration

In chemical and petrochemical plants, these filters are used to remove contaminants from gases and liquids, ensuring the purity of end products and protecting downstream equipment.

Aerospace

In aerospace applications, sintered metal filters ensure that fuel and hydraulic fluids remain free from impurities, thereby enhancing safety and efficiency.

Food and Beverage

These filters ensure the purity and safety of liquids in the food and beverage industry, meeting stringent health standards.

Pharmaceuticals

In the pharmaceutical sector, sintered metal filters are used to sterilize and purify fluids, ensuring the integrity of pharmaceutical products.

Types of Sintered Metal Filters

Stainless Steel Filters

These filters are highly durable and corrosion-resistant, making them suitable for harsh environments. They are commonly used where high mechanical strength is required.

Bronze Filters

Known for their excellent wear resistance, bronze filters are often used in lower pressure applications. They offer a cost-effective solution while maintaining good durability.

Titanium Filters

Titanium filters are known for their exceptional chemical resistance, making them ideal for environments with high corrosion potential. They are used in specialized applications where other materials might fail.

Polyethylene and Polypropylene Filters

These filters are a cost-effective option for less demanding applications. While not as durable as metal filters, they provide sufficient filtration efficiency for many common uses.

Advantages Over Traditional Filters

Sintered metal filters offer several advantages over traditional filtration methods:

- Longevity: They have a longer lifespan compared to ceramic and polymer filters, reducing the need for frequent replacements.

- Efficiency: High filtration accuracy ensures that even the smallest particles are captured, providing superior purity.

- Customization: These filters can be tailored to specific needs, including various shapes, sizes, and porosity levels, making them suitable for a wide range of applications.

Maintenance and Cleaning

Regular maintenance of sintered metal filters is crucial to ensure their optimal performance. Common cleaning methods include ultrasonic baths, chemical cleaning, and backflushing, depending on the application and type of contaminants.

Performance Comparison Table

| Property | Sintered Metal Filter | Ceramic Filter | Polymer Filter |

|---|---|---|---|

| Temperature Range | Up to 1000°C | Up to 300°C | Up to 100°C |

| Chemical Resistance | High | Moderate | Low |

| Reusability | High | Low | Moderate |

| Filtration Precision | High | Moderate | Low |

| Durability | High | Moderate | Low |

How to Choose the Right Sintered Metal Filters

Selecting the right sintered metal filter involves considering several factors:

- Operating Conditions: Evaluate the temperature, pressure, and chemical environment where the filter will be used.

- Filtration Requirements: Determine the required level of filtration accuracy and flow rate.

- Material Compatibility: Ensure that the filter material is compatible with the substances being filtered.

Sintered Metal Filter Manufacturing Process

What is Sintering and Why Use It

What is Sintering?

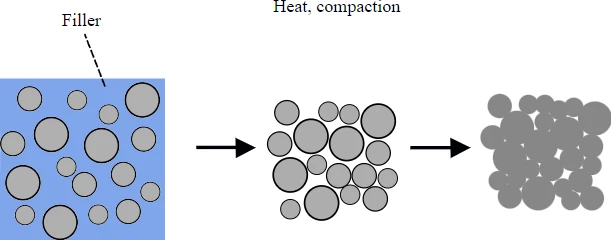

Sintering is a process that involves heating powdered materials to a temperature below their melting point until the particles bond together. This creates a solid, porous structure with high strength and durability.

Why Use Sintering?

The sintering process allows for the production of filters with precise pore sizes and high structural integrity. This method is ideal for creating filters that need to withstand harsh conditions while maintaining excellent filtration efficiency.

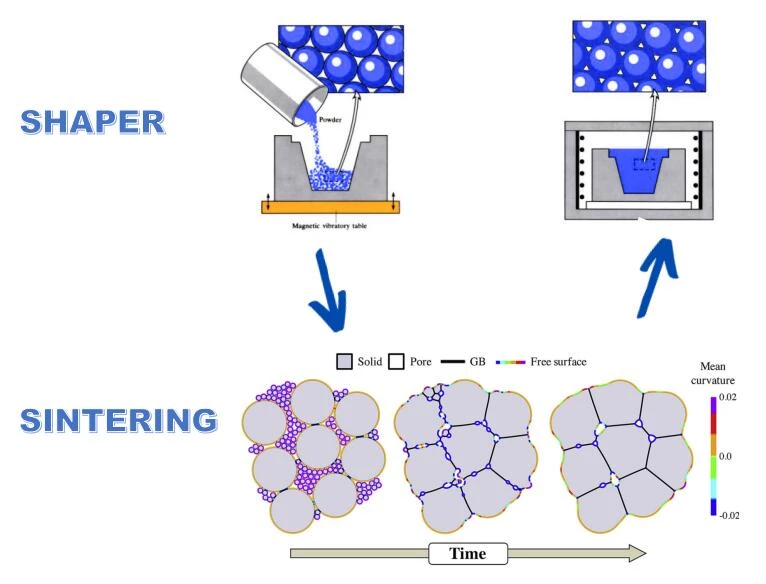

Major Steps in Sintered Metal Filter Manufacturing

Material Preparation

Selecting the appropriate metal powders, such as stainless steel, bronze, or titanium, based on the specific application requirements.

Mold Making

Creating molds to shape the metal powders into the desired filter form. The powders are then loaded into these molds.

Pressing

Applying high pressure to compress the metal powders, ensuring they form a dense and uniform structure.

Sintering

Heating the compressed powders in a furnace to bond the particles together. This process typically occurs in an inert atmosphere to prevent oxidation.

Post-Processing

Depending on the application, the sintered filters may undergo additional treatments such as machining, chemical treatments, or thermal treatments to enhance their properties.

Get Started with Custom Sintered Metal Filters

If you’re looking for high-quality, customizable sintered metal filters, look no further. Our filters are designed to meet the highest standards of durability, efficiency, and chemical resistance, making them suitable for a wide range of applications.

Contact Us Today

Ready to experience the benefits of our custom sintered metal filters? Contact us today to discuss your specific needs and find out how we can help you achieve optimal filtration performance.

Frequently Asked Questions

What materials are used in sintered metal filters?

Sintered metal filters are typically made from stainless steel, bronze, titanium, polyethylene, and polypropylene.

How often should sintered metal filters be cleaned?

The cleaning frequency depends on the application and the level of contamination. However, regular maintenance is recommended to ensure optimal performance.

Can sintered metal filters be customized?

Yes, sintered metal filters can be tailored to meet specific requirements, including different shapes, sizes, and porosity levels.