Importing Floor Drain Covers for Marine and Shipbuilding

Floor drain covers are integral components in the marine and shipbuilding industries, ensuring efficient drainage, maintaining hygiene, and enhancing safety aboard vessels. This article delves into the application, technical benefits, specifications, design considerations, and import aspects of stainless steel 304 perforated floor drain covers specifically for marine and shipbuilding purposes. Additionally, it covers after-sales service, environmental impact, and customization options.

Application of Perforated Floor Drain Covers in Marine and Shipbuilding

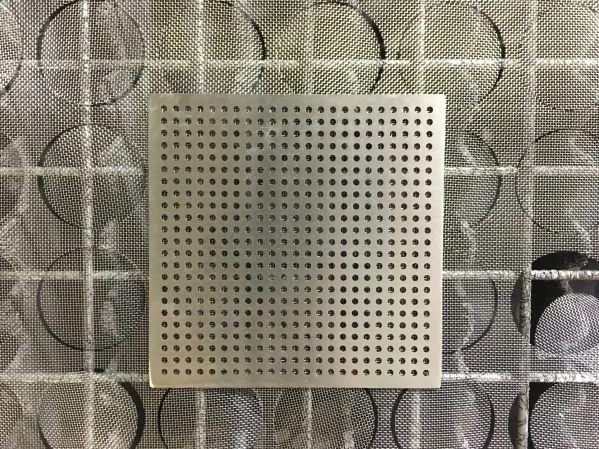

Floor drain covers play a crucial role in marine and shipbuilding environments. These covers facilitate efficient drainage on ships, preventing water accumulation that can lead to slippery surfaces and operational hazards. They are used in various areas such as engine rooms, galleys, and deck areas, where water drainage is essential. The perforated design allows water to flow freely while trapping debris, ensuring a clean and safe environment for crew and passengers.

Technical Benefits of Floor Drain Covers

Stainless steel 304 perforated floor drain covers offer numerous technical benefits:

- Corrosion Resistance: Stainless steel 304 provides excellent resistance to corrosion, crucial in marine environments exposed to saltwater and harsh weather conditions.

- Durability: These drain covers can withstand heavy loads and impacts, ensuring long-term performance even in high-traffic areas.

- Hygiene: The smooth surface of stainless steel is easy to clean, reducing the risk of bacterial growth and maintaining high hygiene standards.

- Strength: Stainless steel 304 is known for its high tensile strength, making it ideal for demanding marine applications.

- Aesthetic Appeal: The polished finish of stainless steel adds a sleek and professional look to marine vessels.

Technical Specifications of Floor Drain Covers

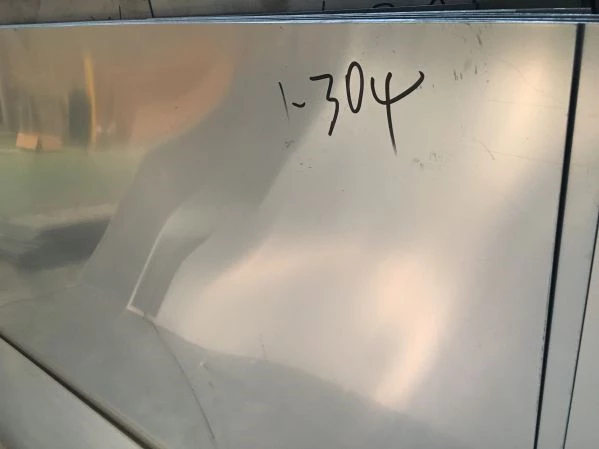

Our stainless steel 304 perforated floor drain covers are designed with precision to meet the stringent requirements of marine and shipbuilding applications. Key specifications include:

- Thickness: 1mm to 2mm, customizable to specific needs.

- Shape: Available in round and square shapes, with custom shapes also available.

- Diameter: Ranges from 30mm to 180mm, with options for non-standard sizes.

- Finish: Choose from brushed, polished, or matte finishes to match the aesthetic requirements.

- Perforation Patterns: Options include round holes, square holes, slotted holes, and custom patterns. For more information on optimizing perforation patterns, read this article Optimizing Perforation Patterns for Efficient Drain Covers.

Design Considerations for Floor Drain Covers in Marine and Shipbuilding

Designing floor drain covers for marine and shipbuilding involves several critical considerations:

- Load Capacity: Ensure the covers can handle the weight of heavy equipment and foot traffic.

- Anti-Slip Surface: Incorporate anti-slip textures to enhance safety on wet surfaces.

- Drainage Efficiency: Optimize perforation patterns to allow maximum water flow while trapping debris.

- Ease of Installation: Design covers for easy installation and removal to facilitate maintenance.

- Compliance with Marine Standards: Ensure designs meet international marine safety and quality standards.

Import Procedures for Floor Drain Covers

Importing floor drain covers for marine and shipbuilding requires a clear understanding of the import procedures. This includes:

- Documentation: Ensure all necessary documentation, such as commercial invoices, packing lists, and certificates of origin, are accurately prepared.

- Compliance with Regulations: Adhere to the import regulations of the destination country, including safety and environmental standards.

- Customs Clearance: Work with experienced customs brokers to navigate the customs clearance process efficiently.

- Quality Assurance: Implement strict quality control measures to ensure the products meet the specified standards before shipment.

Import Standards for Floor Drain Covers

When importing floor drain covers, it is crucial to adhere to the following standards:

- International Marine Standards: Ensure compliance with standards such as the International Maritime Organization (IMO) regulations and the American Bureau of Shipping (ABS) guidelines.

- Material Specifications: Verify that the stainless steel 304 used meets the ASTM standards for corrosion resistance and durability.

- Environmental Standards: Adhere to environmental regulations, such as the REACH and RoHS directives, to ensure the products are free from harmful substances.

- Safety Standards: Confirm that the floor drain covers meet the safety standards for slip resistance and load-bearing capacity.

After-Sales Service

We understand the importance of reliable after-sales service in maintaining long-term relationships with our clients. Our after-sales service includes:

- Technical Support: Our team of experts provides ongoing technical support to ensure optimal product performance.

- Maintenance Guidance: We offer detailed maintenance guides to help clients keep their floor drain covers in top condition.

- Replacement Parts: We provide quick access to replacement parts to minimize downtime and maintain operational efficiency.

- Customer Feedback: We actively seek and incorporate customer feedback to continually improve our products and services.

Environmental Impact and Sustainability

Stainless steel 304 perforated floor drain covers contribute positively to environmental sustainability. Key aspects include:

- Recyclability: Stainless steel is 100% recyclable, reducing the environmental impact and promoting sustainable practices.

- Durability: The long lifespan of stainless steel products reduces the need for frequent replacements, minimizing waste.

- Corrosion Resistance: The inherent corrosion resistance of stainless steel eliminates the need for harmful coatings and treatments.

- Energy Efficiency: Advanced manufacturing processes used in producing stainless steel drain covers are designed to be energy-efficient and environmentally friendly.

Customize Your Floor Drain Covers from Our Factory

Overview of the Customization Process

Our customization process is designed to provide tailored solutions that meet the specific requirements of our clients. Here’s an overview of the process:

- Consultation: We begin with a thorough consultation to understand your needs and preferences.

- Design: Our design team creates detailed plans based on your specifications.

- Production: Using advanced manufacturing techniques, we produce the customized floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

Benefits of Custom Solutions Tailored to Marine and Shipbuilding

Customizing floor drain covers for marine and shipbuilding offers several benefits:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance the durability and performance of the covers.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team is ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.