Improving Acoustics with Stainless Steel Perforated Panels

Stainless steel perforated panels are a versatile and effective solution for improving acoustics in various environments. These panels not only enhance sound quality but also provide aesthetic appeal and durability. This article explores the benefits, applications, design features, and customization options for stainless steel perforated panels in acoustic treatments.

Importance of Acoustic Panels

Acoustic panels are crucial in managing sound quality in various settings, including commercial, industrial, and residential spaces. They help reduce noise, control sound reflections, and enhance speech intelligibility. Stainless steel perforated panels offer a durable and visually appealing solution for acoustic treatments.

Benefits of Stainless Steel Perforated Panels

Stainless steel perforated panels offer several advantages for acoustic applications:

- Durability: Resistant to corrosion and wear, ensuring long-lasting performance.

- Aesthetic Appeal: Available in various finishes and patterns, enhancing the visual appeal of spaces.

- Fire Resistance: Non-combustible, providing safety in fire-prone areas.

- Hygiene: Easy to clean, making them suitable for hygienic environments.

- Versatility: Customizable in terms of size, shape, and perforation patterns to meet specific acoustic needs.

How Perforated Panels Improve Acoustics

Perforated panels improve acoustics by absorbing and diffusing sound waves. The perforations in the panels allow sound waves to enter, where they are absorbed by an underlying layer of sound-absorbing material. This process reduces noise levels, minimizes echoes, and enhances sound quality.

Sound Absorption

Sound absorption is a critical aspect of acoustic treatments. Stainless steel perforated panels enhance sound absorption by allowing sound waves to pass through the perforations and into an absorptive material, such as mineral wool or acoustic foam, placed behind the panels. This setup effectively reduces reverberation and background noise.

Sound Diffusion

Sound diffusion involves scattering sound waves to create a more balanced and natural sound environment. Perforated panels diffuse sound by breaking up direct sound waves, reducing hotspots and dead zones. This results in a more uniform distribution of sound, improving overall acoustic quality.

Applications of Stainless Steel Perforated Panels in Acoustics

Stainless steel perforated panels are used in various acoustic applications across different industries. Some common applications include:

Commercial Spaces

In commercial spaces like offices, conference rooms, and lobbies, stainless steel perforated panels help create a comfortable acoustic environment by reducing noise levels and improving speech intelligibility. They can be used as wall and ceiling panels, partitions, and decorative elements.

Industrial Settings

Industrial settings often have high noise levels due to machinery and equipment. Stainless steel perforated panels can be used to create acoustic enclosures, barriers, and partitions that reduce noise pollution and protect workers’ hearing.

Auditoriums and Theaters

In auditoriums and theaters, acoustic quality is paramount. Stainless steel perforated panels enhance sound quality by absorbing and diffusing sound waves, ensuring clear and balanced audio for audiences. These panels can be integrated into walls, ceilings, and stage elements.

Residential Areas

In residential areas, stainless steel perforated panels can be used to improve the acoustic environment in home theaters, music rooms, and living spaces. They provide an effective solution for managing noise and enhancing sound quality in domestic settings.

Healthcare Facilities

Healthcare facilities require quiet environments for patient comfort and recovery. Stainless steel perforated panels help reduce noise levels in hospitals, clinics, and nursing homes, contributing to a more serene atmosphere. Their hygienic properties also make them suitable for sterile environments.

Transportation Hubs

Transportation hubs like airports, train stations, and bus terminals are often noisy. Stainless steel perforated panels can be used to manage noise levels in these areas, creating a more pleasant experience for travelers. They can be installed as wall and ceiling panels, as well as decorative elements.

Design Features of Stainless Steel Perforated Panels

Stainless steel perforated panels come with various design features that enhance their acoustic performance and aesthetic appeal.

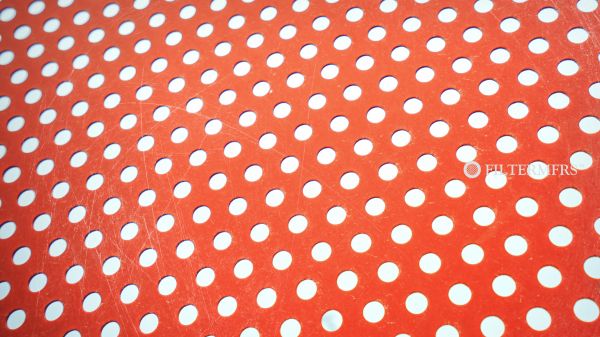

Perforation Patterns

The perforation pattern of the panels significantly affects their acoustic properties. Common patterns include round holes, square holes, slotted holes, and custom designs. The size, shape, and arrangement of the perforations can be customized to achieve the desired acoustic performance.

Panel Thickness

Panel thickness plays a role in the durability and acoustic properties of the panels. Thicker panels offer better sound absorption and durability, making them suitable for high-traffic areas and industrial applications.

Finishing Options

Stainless steel perforated panels are available in various finishes, including brushed, polished, matte, and powder-coated. These finishes enhance the visual appeal of the panels and provide additional protection against corrosion and wear.

Mounting Systems

Mounting systems for stainless steel perforated panels can be customized to meet specific installation requirements. Common mounting options include direct mount, suspended mount, and modular systems. The choice of mounting system affects the ease of installation and the overall aesthetic of the space.

Data on Acoustic Performance of Perforated Panels

Sound Absorption Coefficients

The sound absorption coefficient (SAC) measures the effectiveness of a material in absorbing sound. SAC values range from 0 to 1, with higher values indicating better absorption. Perforated panels typically have SAC values between 0.5 and 0.95, depending on the perforation pattern, panel thickness, and backing material.

| Perforation Pattern | Panel Thickness (mm) | SAC (Frequency: 500 Hz) | SAC (Frequency: 1000 Hz) |

|---|---|---|---|

| Round Holes | 1.5 | 0.60 | 0.75 |

| Square Holes | 2.0 | 0.65 | 0.80 |

| Slotted Holes | 2.5 | 0.70 | 0.85 |

| Custom Design | 3.0 | 0.75 | 0.90 |

Noise Reduction Coefficients

The noise reduction coefficient (NRC) is an average of SAC values at different frequencies, providing an overall measure of a material’s sound-absorbing performance. Perforated panels with an NRC of 0.70 to 0.95 are considered highly effective for acoustic treatments.

| Perforation Pattern | NRC |

|---|---|

| Round Holes | 0.75 |

| Square Holes | 0.80 |

| Slotted Holes | 0.85 |

| Custom Design | 0.90 |

Customization Options for Stainless Steel Perforated Panels

Custom Patterns and Designs

Manufacturers can customize perforated panels with various patterns and designs to meet specific acoustic and aesthetic requirements. This flexibility allows for unique styling options and enhanced performance characteristics.

Material Selection

Stainless steel perforated panels can be customized with different grades of stainless steel, such as SS 304, SS 316, and SS 430, depending on the application’s requirements. This variety ensures that the selected material offers the best combination of strength, durability, and corrosion resistance.

Finishing Options

Various finishing options, such as powder coating and anodizing, can be applied to stainless steel perforated panels to enhance their appearance and resistance to corrosion. These finishes also add an extra layer of protection, extending the lifespan of the panels.

Mounting and Installation

Manufacturers offer a range of mounting and installation options for stainless steel perforated panels. This includes direct mounting, suspended systems, and modular installations, allowing for easy and flexible installation to suit different acoustic requirements.

Future Trends in Acoustic Panel Design

The use of stainless steel perforated panels in acoustic treatments is expected to grow, driven by advancements in materials science and acoustic engineering.

Advanced Materials

The development of advanced materials, such as high-strength alloys and composites, will expand the range of applications for perforated panels. These materials offer improved performance characteristics, making them suitable for more demanding acoustic treatments.

Innovative Manufacturing Techniques

Advancements in manufacturing techniques, such as additive manufacturing and precision laser cutting, will enable the production of more complex and precise perforated panels. These innovations will enhance the design flexibility and performance of acoustic panels.

Sustainable Practices

Sustainability is becoming increasingly important in building design and construction. The use of recyclable materials like stainless steel and energy-efficient manufacturing processes will contribute to more sustainable acoustic solutions.

Customize Your Stainless Steel Perforated Panels from Our Factory

Overview of the Customization Process

Our customization process ensures each stainless steel perforated panel meets the unique requirements of our clients:

- Consultation: Understand your specific needs and preferences through detailed consultation.

- Design: Create detailed plans based on your specifications, ensuring a perfect fit and optimal performance.

- Production: Utilize advanced manufacturing techniques to produce customized perforated panels to exacting