Effective drainage solutions are essential for maintaining cleanliness, safety, and operational efficiency in warehousing facilities. High-quality floor drain covers play a crucial role in ensuring that these environments remain free of water accumulation and debris. As a wholesaler of floor drain covers, we offer a range of products designed to meet the specific needs of warehousing facilities. This article delves into the technical benefits, specifications, design considerations, and our comprehensive customization and after-sales services.

Technical Benefits of Floor Drain Covers

Floor drain covers provide several technical benefits that are particularly valuable in warehousing facilities:

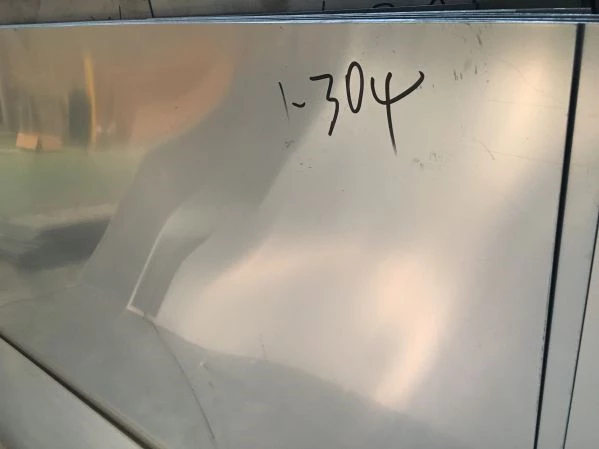

- Durability: Made from stainless steel 304, our floor drain covers resist corrosion and withstand heavy loads, making them ideal for high-traffic areas.

- Hygiene: Stainless steel is easy to clean and maintain, ensuring high hygiene standards in warehouses where cleanliness is paramount.

- Safety: Properly installed floor drain covers prevent water accumulation, reducing the risk of slip hazards and ensuring a safer working environment.

- Efficiency: Efficient drainage systems prevent operational disruptions caused by water damage, protecting goods and equipment stored in the warehouse.

Technical Specifications of Floor Drain Covers

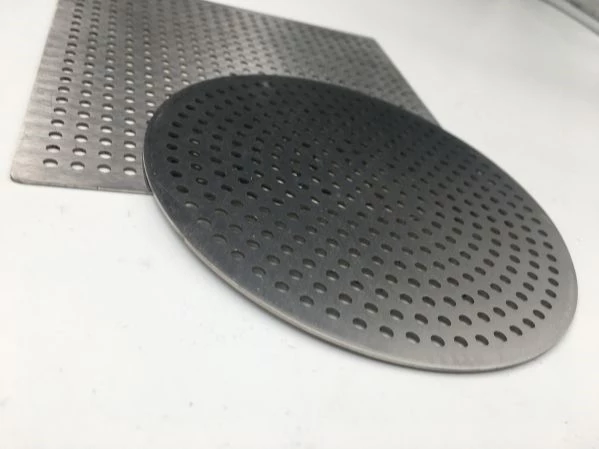

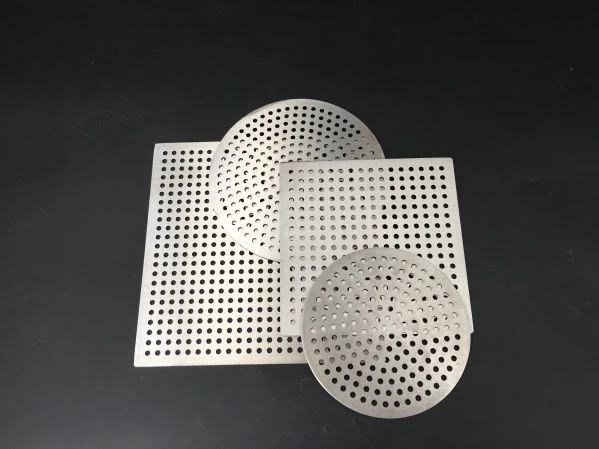

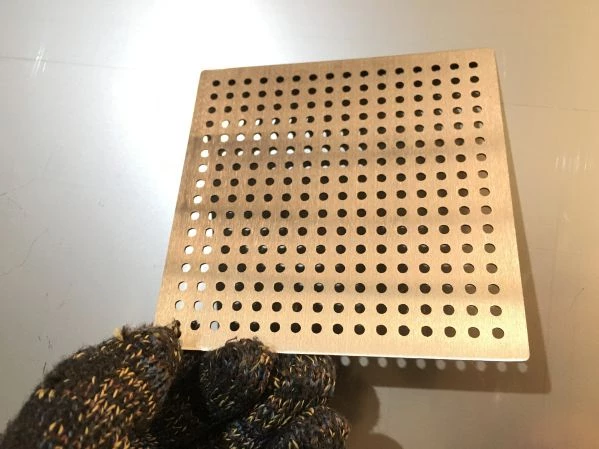

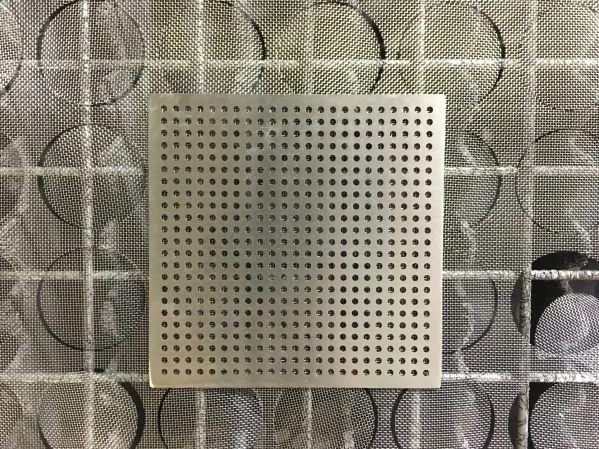

Our stainless steel 304 perforated floor drain covers are designed with the following technical specifications to meet the diverse needs of warehousing facilities:

- Thickness: 1mm to 2mm, customizable to specific requirements.

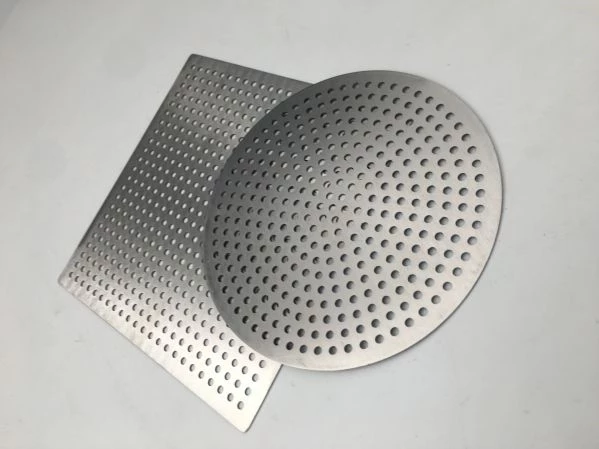

- Shape: Available in round and square shapes, with custom shapes also available.

- Diameter: Ranges from 30mm to 180mm, with options for non-standard sizes.

- Finish: Choose from brushed, polished, or matte finishes to suit your facility’s aesthetics.

- Perforation Patterns: Options include round holes, square holes, slotted holes, and custom patterns. For more information on optimizing perforation patterns, read this article Optimizing Perforation Patterns for Efficient Drain Covers.

These specifications ensure that our floor drain covers exceed the operational demands of facilities worldwide.

Design Considerations for Floor Drain Covers in Warehousing Facilities

Designing floor drain covers for warehousing facilities requires careful consideration of several factors:

- Load-Bearing Capacity: Ensure the drain covers can withstand the weight of forklifts, pallet jacks, and other heavy equipment commonly used in warehouses.

- Drainage Efficiency: Select perforation patterns that facilitate rapid water drainage while preventing debris from entering the drainage system.

- Ease of Maintenance: Design covers that can be easily removed and cleaned to maintain optimal drainage performance and hygiene.

- Aesthetic Integration: Choose finishes and shapes that blend seamlessly with the warehouse environment, contributing to a professional appearance.

Benefits of Partnering with a Wholesaler

Partnering with a wholesaler for floor drain covers offers several advantages for warehousing facilities:

- Bulk Pricing: Wholesalers can provide competitive pricing for large orders, helping to reduce overall costs.

- Consistent Supply: Ensure a steady supply of drain covers to meet ongoing maintenance and replacement needs.

- Quality Assurance: Reputable wholesalers guarantee high-quality products that comply with industry standards.

- Customization Options: Wholesalers often offer customization to meet the specific requirements of different facilities.

Choosing the Right Wholesaler for Floor Drain Covers

Selecting the right wholesaler for floor drain covers involves considering several key factors:

- Reputation: Look for wholesalers with a proven track record and positive customer reviews.

- Product Range: Ensure the wholesaler offers a wide range of designs and specifications to meet your specific needs.

- Customization Services: Choose a wholesaler that provides custom solutions to tailor drain covers to your facility’s requirements.

- Technical Support: Opt for wholesalers who offer technical support and guidance throughout the purchasing process.

- Delivery Efficiency: Evaluate the wholesaler’s ability to deliver products on time and handle large-scale orders efficiently.

Manufacturing Process of Floor Drain Covers in Our Factory

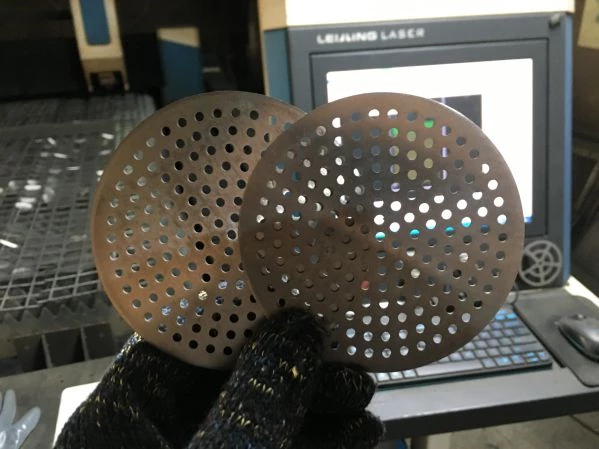

Our manufacturing process for stainless steel 304 perforated floor drain covers ensures high-quality and precision:

- Material Selection: We use premium stainless steel 304 for its strength, durability, and corrosion resistance.

- Design and Engineering: Our team designs each drain cover to meet specific client requirements, focusing on functionality and aesthetics.

- Cutting and Perforation: Advanced CNC machines cut and perforate the stainless steel sheets with precision, ensuring consistent quality.

- Finishing: We offer various finishes, including brushed, polished, and matte, to match the desired aesthetic and functional requirements.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards before shipping.

After-Sales Service

Our commitment to customer satisfaction extends beyond the sale. We offer comprehensive after-sales services to ensure the longevity and performance of our floor drain covers:

- Technical Support: Our experts provide ongoing support to address any technical issues or questions.

- Maintenance Guidance: We offer detailed maintenance instructions to help clients keep their drain covers in top condition.

- Replacement Parts: We provide access to replacement parts to minimize downtime and maintain operational efficiency.

- Customer Feedback: We actively seek and incorporate customer feedback to continuously improve our products and services.

Customize Your Floor Drain Covers from Our Factory

Overview of the Customization Process

Our customization process is designed to provide tailored solutions that meet the specific requirements of warehousing facilities. Here’s an overview of the process:

- Consultation: We begin with a thorough consultation to understand your needs and preferences.

- Design: Our design team creates detailed plans based on your specifications.

- Production: Using advanced manufacturing techniques, we produce the customized floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

The Benefits of Custom Solutions Tailored to Specific Warehousing Facilities Requirements

Custom floor drain covers offer several benefits tailored to the unique needs of warehousing facilities:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance the durability and performance of the covers.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team is ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.