Stainless steel floor drain cover plates are essential in various industrial and commercial settings due to their durability, efficiency, and hygienic properties. These covers ensure smooth drainage, prevent clogging, and maintain cleanliness in high-traffic environments. This article delves into the top benefits of using stainless steel floor drain cover plates, their specifications, and the customization options available to meet specific needs.

Superior Durability and Strength

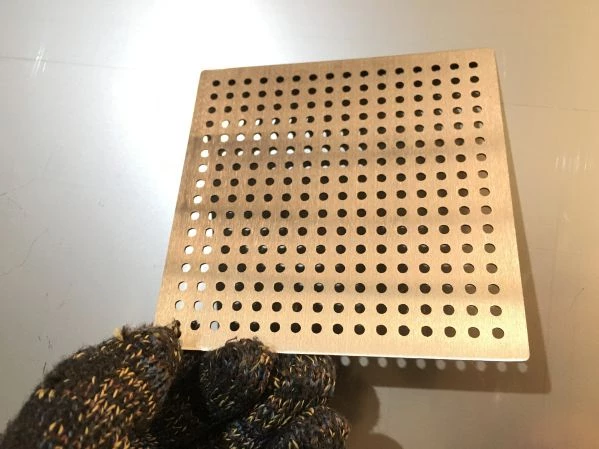

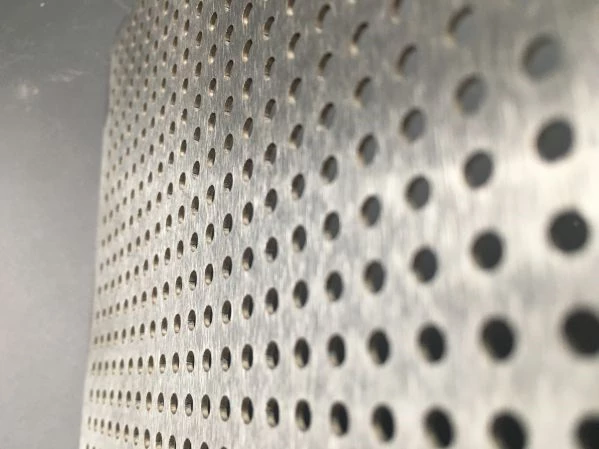

Stainless steel 304 floor drain cover plates offer exceptional durability and strength, making them ideal for heavy-duty applications. Their robust construction allows them to withstand significant loads and resist deformation, ensuring long-lasting performance in demanding environments. These covers can handle the weight of heavy machinery and high foot traffic without compromising their structural integrity.

Impact Resistance

One of the critical features of stainless steel floor drain cover plates is their resistance to impact. This property ensures that the covers remain intact and functional even when subjected to heavy objects or equipment. This makes them suitable for industries such as manufacturing, warehousing, and food processing, where the risk of impact damage is high.

Long-Term Performance

Stainless steel 304 is known for its long-term performance. It maintains its structural properties and appearance over time, reducing the need for frequent replacements. This longevity translates to cost savings for businesses, as they can invest in high-quality drain covers that provide reliable service for years.

Corrosion Resistance

Stainless steel 304 offers excellent resistance to corrosion, making it suitable for environments exposed to moisture, chemicals, and other corrosive substances. This property is particularly beneficial in industries where hygiene and cleanliness are paramount, such as food processing, pharmaceuticals, and chemical processing.

Chemical Resistance

In addition to moisture, stainless steel 304 resists various chemicals commonly found in industrial settings. This resistance ensures that the drain covers do not degrade or corrode when exposed to cleaning agents, acids, or other harsh chemicals, maintaining their functionality and appearance.

Hygienic Properties

Corrosion resistance also contributes to the hygienic properties of stainless steel floor drain cover plates. They do not harbor bacteria or other microorganisms, ensuring that they remain clean and sanitary. This is crucial in industries where maintaining high hygiene standards is essential to prevent contamination.

Ease of Maintenance

Maintaining stainless steel floor drain cover plates is straightforward and cost-effective. Their smooth surface and resistance to stains make them easy to clean, ensuring that they remain functional and visually appealing.

Cleaning and Sanitation

Regular cleaning of stainless steel drain covers requires minimal effort. Standard cleaning agents and water are sufficient to remove dirt, grime, and other contaminants. Additionally, their resistance to corrosion and staining ensures that they maintain a clean and polished appearance over time.

Minimal Maintenance Costs

The durability and resistance properties of stainless steel 304 reduce the need for frequent maintenance and replacements. This minimizes maintenance costs for businesses, allowing them to allocate resources to other critical areas.

Versatile Design Options

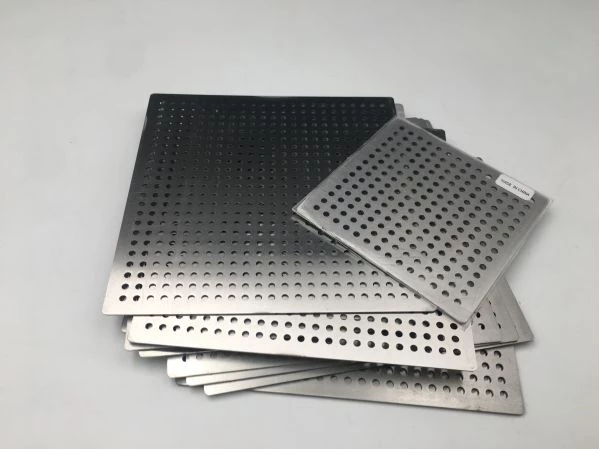

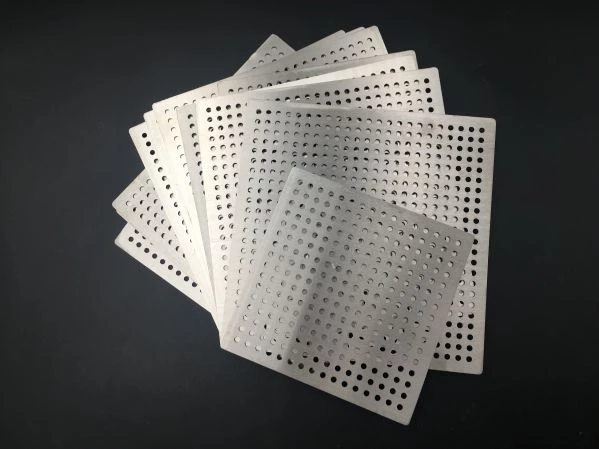

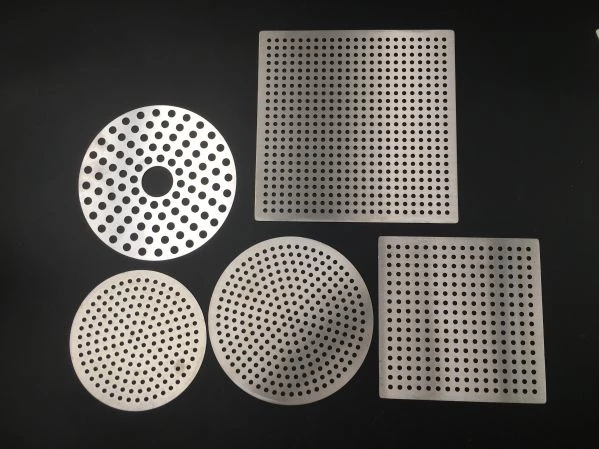

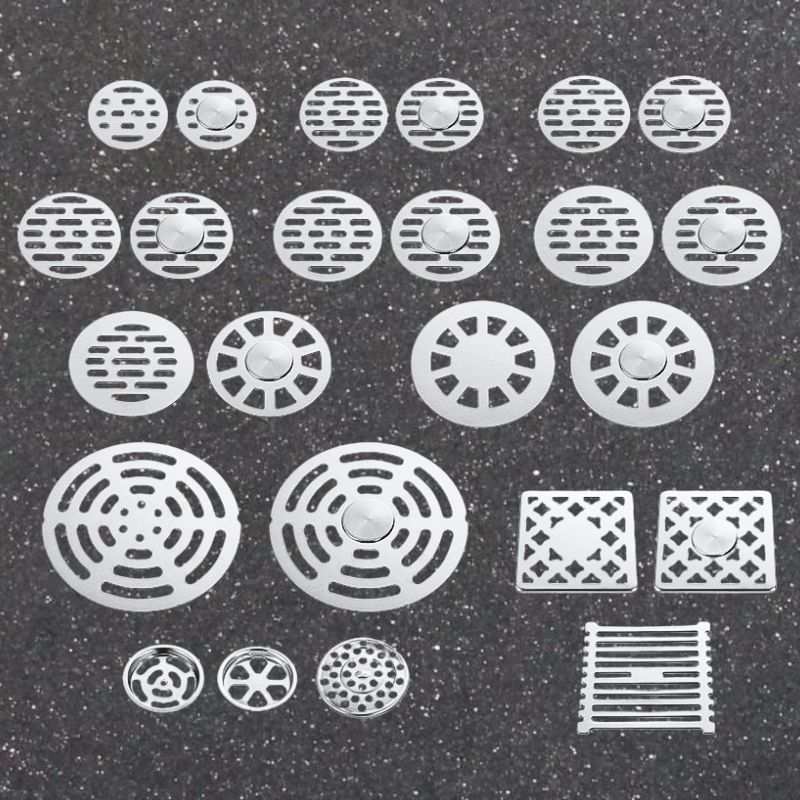

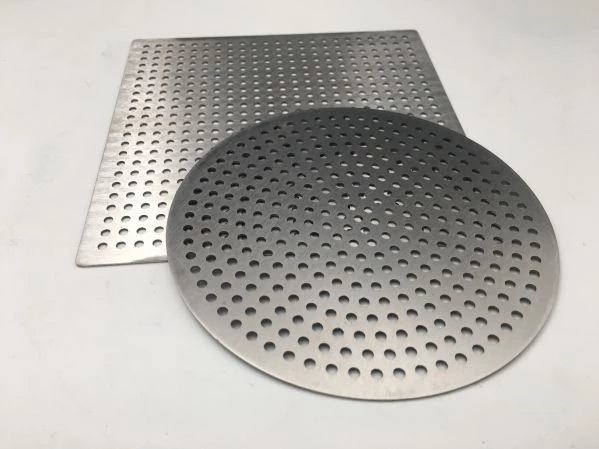

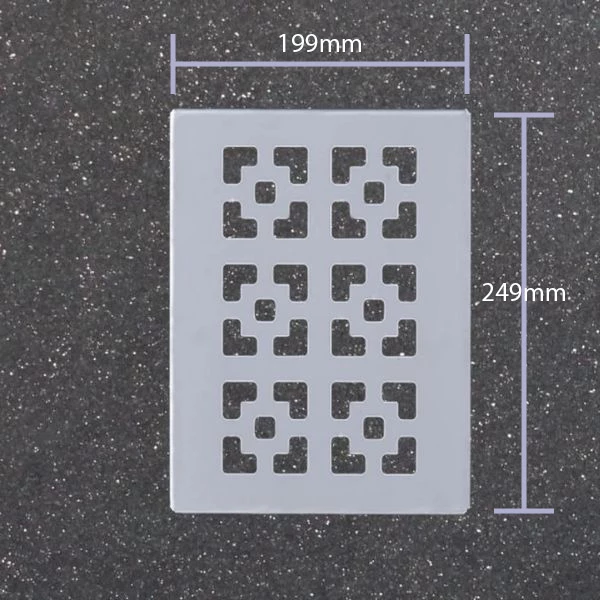

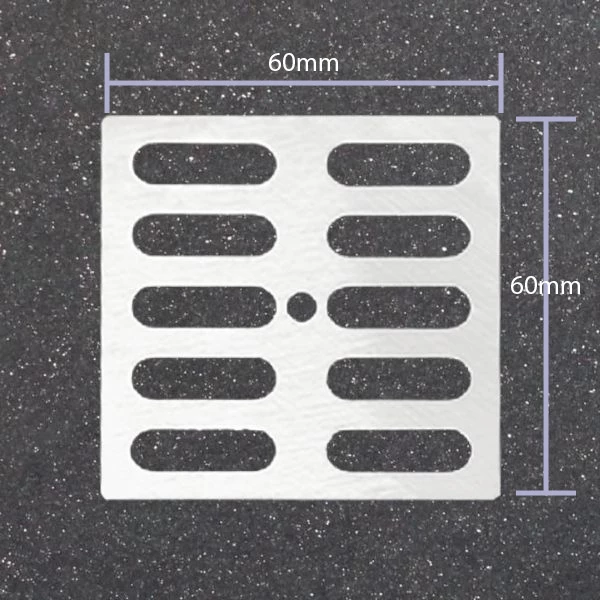

Stainless steel floor drain cover plates offer versatile design options to meet the specific needs of various industries. Customizable features include thickness, shape, size, finish, and perforation patterns.

Customizable Specifications

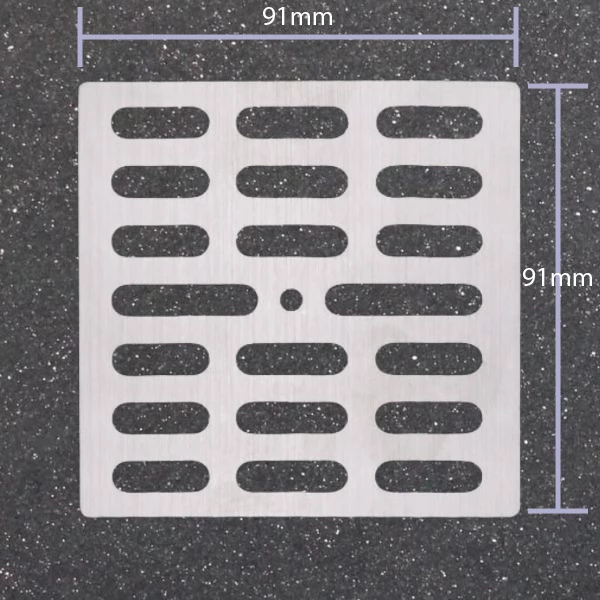

- Thickness: Available in 1mm to 2mm, customizable to specific requirements.

- Shape: Offered in both round and square shapes, with custom shapes also available.

- Diameter: Ranges from 30mm to 180mm, with options for non-standard sizes.

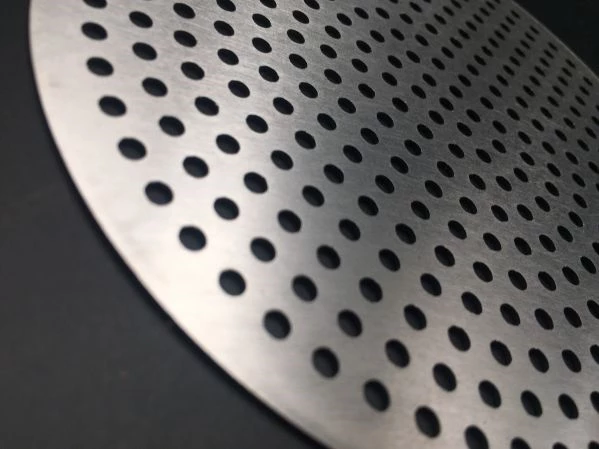

- Finish: Choose from brushed, polished, or matte finishes.

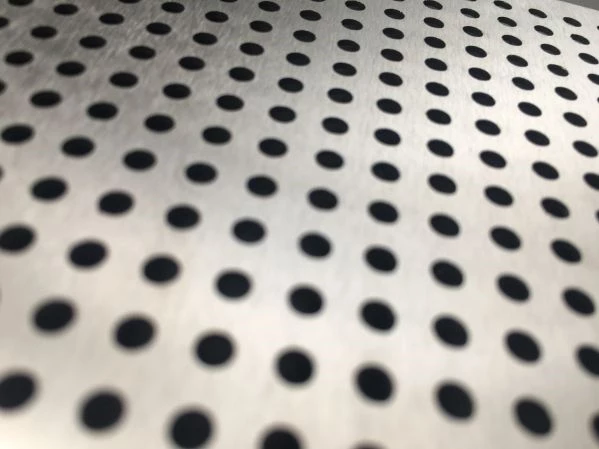

- Perforation Patterns: Options include round holes, square holes, slotted holes, and custom patterns.

Aesthetic Appeal

Custom finishes and patterns enhance the aesthetic appeal of stainless steel floor drain cover plates. This is particularly important in commercial settings where visual appeal is as crucial as functionality. The ability to customize the appearance ensures that the drain covers blend seamlessly with the overall design of the facility.

Enhanced Safety Features

Safety is a critical consideration in industrial and commercial settings. Stainless steel floor drain cover plates can be designed with enhanced safety features to reduce the risk of accidents and injuries.

Anti-Slip Surfaces

One of the key safety features is the inclusion of anti-slip surfaces. These surfaces provide additional traction, reducing the risk of slips and falls in areas where water or other liquids may be present. This is particularly beneficial in environments such as kitchens, food processing plants, and manufacturing facilities.

Load-Bearing Capacity

Customizing the thickness and reinforcement of the drain covers enhances their load-bearing capacity. This ensures that the covers can safely support the weight of heavy machinery and equipment, preventing accidents caused by structural failure.

Applications in Various Industries

Stainless steel floor drain cover plates are suitable for a wide range of industries due to their versatility, durability, and hygienic properties.

Food Processing Industry

In the food processing industry, maintaining strict hygiene standards is essential. Stainless steel drain cover plates prevent contamination and ensure efficient drainage, helping facilities meet stringent health regulations.

Pharmaceutical Industry

Pharmaceutical manufacturing requires a clean and sterile environment. Stainless steel 304 drain cover plates offer excellent resistance to chemicals and easy cleaning, making them ideal for this industry.

Chemical Processing Industry

Chemical processing plants deal with corrosive substances and require durable drainage solutions. Stainless steel floor drain cover plates provide the necessary corrosion resistance and strength to handle these challenging conditions.

Beverage Production Industry

Beverage production facilities need efficient drainage to manage spills and maintain cleanliness. Custom stainless steel drain cover plates ensure smooth water flow and prevent debris from clogging the system.

Innovative Design Features

Our custom floor drain cover plates incorporate innovative design features that enhance their performance and usability.

Modular Design

Our covers can be designed with modular components, allowing for easy replacement and maintenance. This feature ensures that the drain covers can be quickly and efficiently serviced, minimizing downtime.

Integrated Filters

Custom covers can include integrated filters to trap smaller debris, preventing clogs and ensuring smooth drainage. This feature is particularly beneficial in industries where small particles and debris are common.

Adjustable Heights

We offer designs with adjustable heights to accommodate different floor levels and drainage needs. This customization ensures that the drain covers fit perfectly in various settings, providing optimal performance.

Locking Mechanisms

For added security, our covers can be equipped with locking mechanisms to prevent unauthorized removal. This feature ensures that the drain covers remain in place, maintaining the integrity of the drainage system.

Customization Options for Floor Drain Cover Plates

Overview of the Customization Process

Our customization process ensures that each floor drain cover plate meets the unique requirements of our clients:

- Consultation: We start with a detailed consultation to understand your specific needs and preferences.

- Design: Our design team creates detailed plans based on your specifications, ensuring a perfect fit and optimal performance.

- Production: We utilize advanced manufacturing techniques to produce the customized floor drain cover plates to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

Benefits of Custom Solutions

Customizing floor drain cover plates offers several benefits:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance the durability and performance of the covers.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

After-Sales Service

Reliable after-sales service is crucial for maintaining long-term relationships with our clients. Our after-sales service includes:

- Technical Support: Our team of experts provides ongoing technical support to ensure optimal product performance.

- Maintenance Guidance: We offer detailed maintenance guides to help clients keep their floor drain cover plates in top condition.

- Replacement Parts: We provide quick access to replacement parts to minimize downtime and maintain operational efficiency.

- Customer Feedback: We actively seek and incorporate customer feedback to continually improve our products and services.

Contact Us

Enterprise customers interested in custom floor drain cover plates can contact us by submitting the form on our website. Our team is ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.