Hotels and resorts demand high standards of hygiene, aesthetics, and functionality in their bathrooms. Shower floor drain covers contribute significantly to maintaining these standards. Custom solutions offer enhanced design flexibility, ensuring that the specific needs of hospitality environments are met. This article explores the importance of custom shower floor drain covers, their design and technical features, and the benefits they bring to hotels and resorts.

Ensuring Cleanliness with Custom Shower Floor Drain Covers

Maintaining cleanliness in hotel and resort bathrooms requires efficient drainage solutions. Custom shower floor drain covers prevent clogs, facilitate easy cleaning, and support hygiene. By selecting custom solutions, hotels and resorts can address unique design challenges and achieve superior functionality.

Design Features of Shower Floor Drain Covers

Utilizing High-Quality Materials

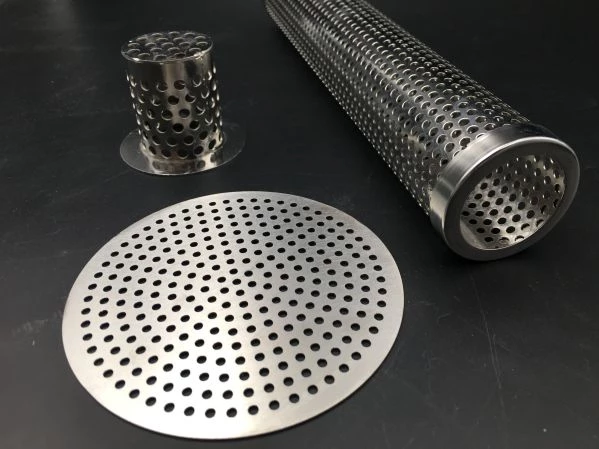

Our custom shower floor drain covers use high-quality materials like stainless steel 304, known for durability and corrosion resistance. Stainless steel offers longevity, making it ideal for high-moisture environments like hotel bathrooms.

Enhancing Aesthetic Appeal

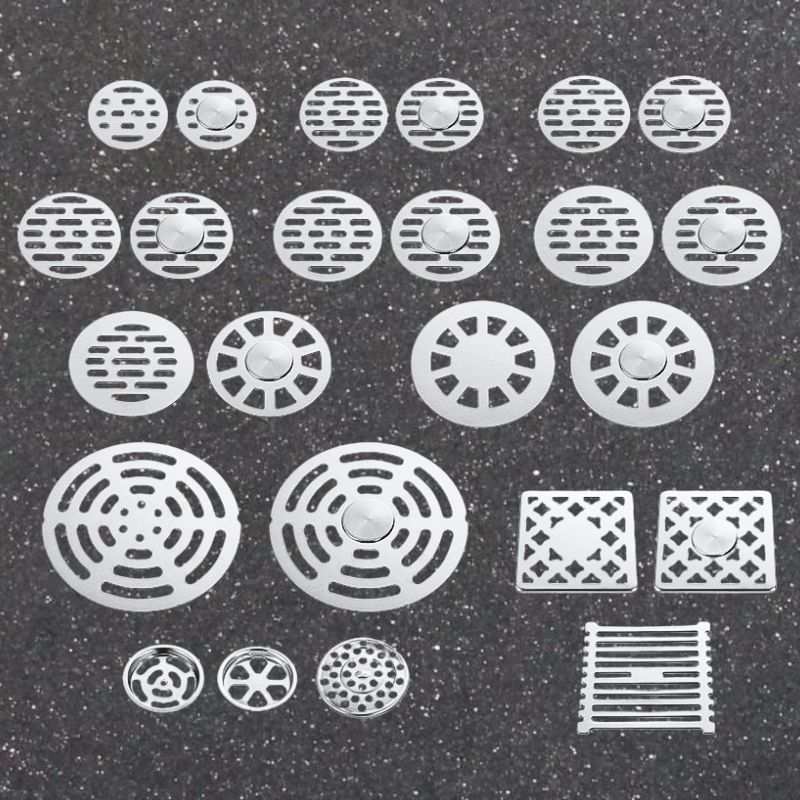

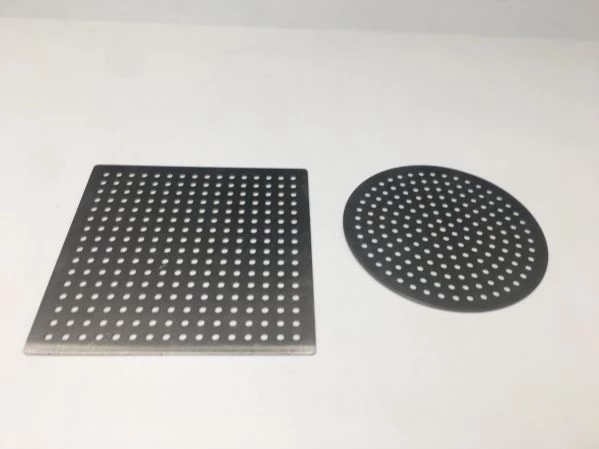

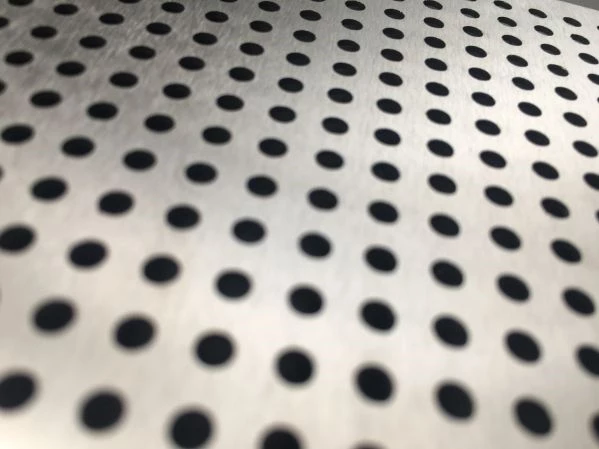

Custom shower floor drain covers can be tailored to match the bathroom’s design theme. Options include various finishes like brushed, polished, or matte, and a range of perforation patterns to complement the decor.

Improving Safety

Providing a safe environment for guests involves implementing features that reduce risks. Our shower floor drain covers can be designed with anti-slip surfaces to minimize slips and falls.

Technical Specifications of Custom Shower Floor Drain Covers

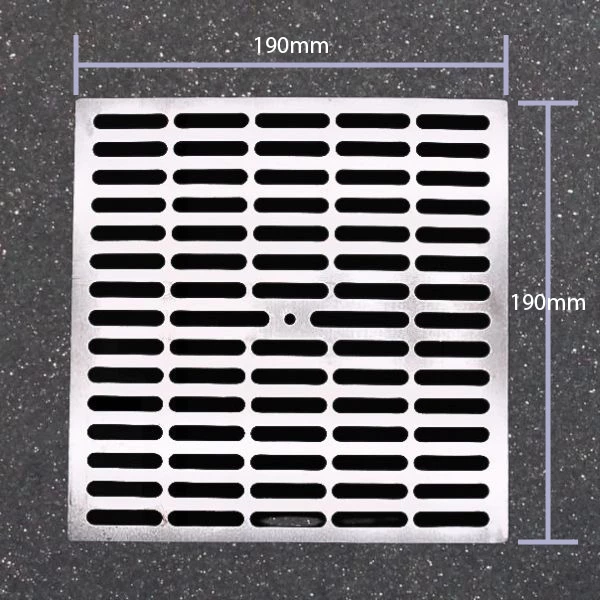

Thickness and Dimensions

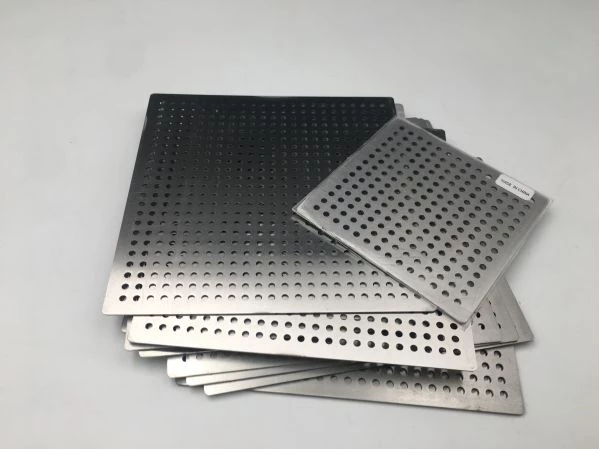

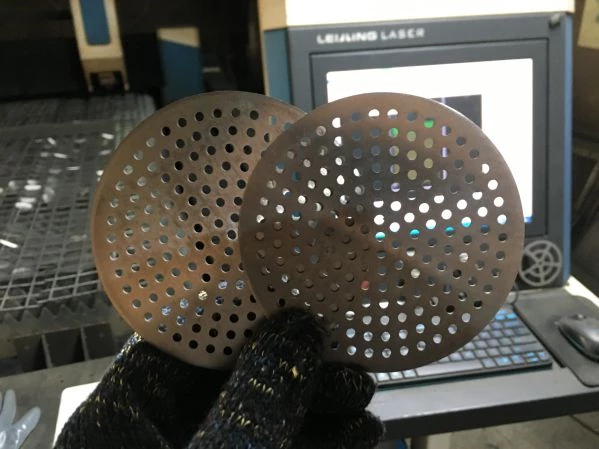

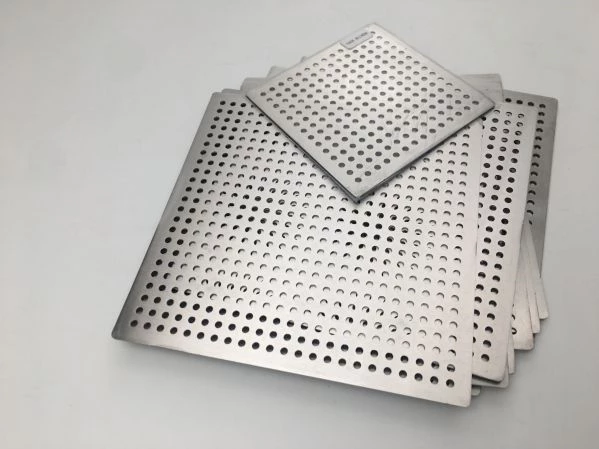

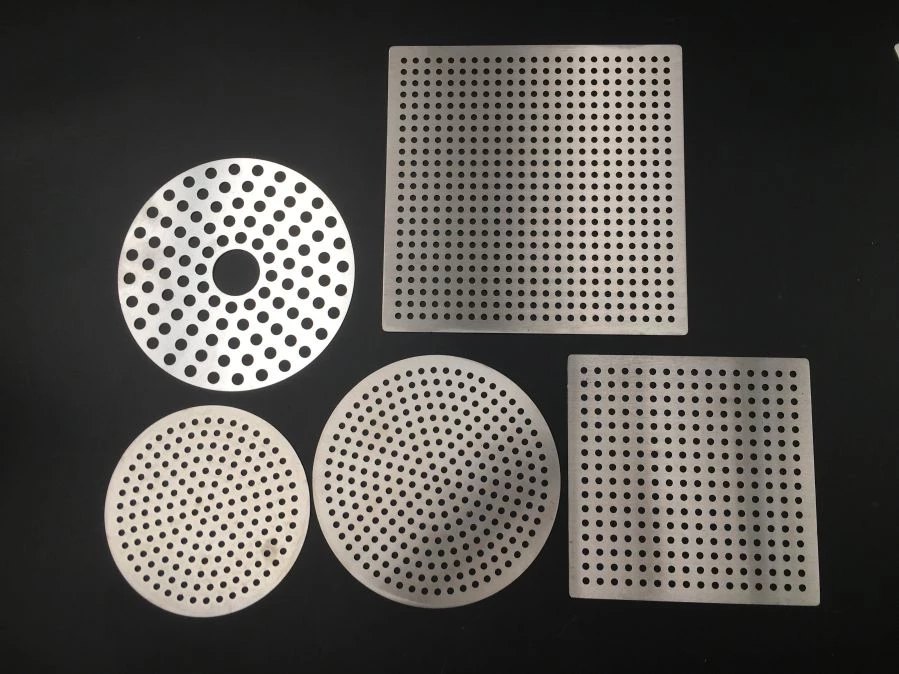

Our custom shower floor drain covers range in thickness from 1mm to 2mm, ensuring robustness. Available in various shapes, including round and square, they can be customized to specific dimensions from 30mm to 180mm in diameter.

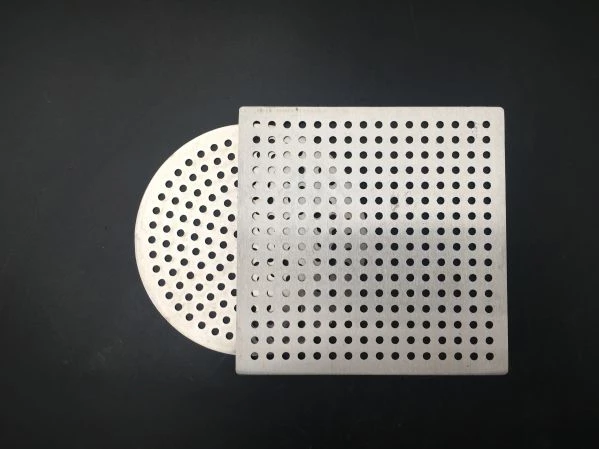

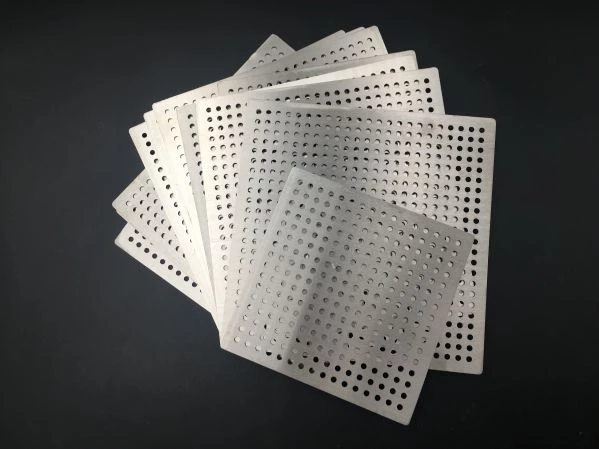

Perforation Patterns

Custom perforation patterns, such as round holes, square holes, and slotted holes, can be tailored to meet specific drainage needs and aesthetic preferences. These patterns ensure efficient water flow while preventing debris from clogging the drain.

Finishes

Choose from brushed, polished, or matte finishes. Each finish offers distinct visual and functional benefits, allowing hotels and resorts to select the best option for their design and maintenance requirements.

Economic Benefits of Custom Shower Floor Drain Covers

Achieving Long-Term Durability

Investing in high-quality materials like stainless steel 304 ensures the drain covers withstand frequent use and exposure to water and cleaning agents. This durability translates to long-term cost savings for hotels and resorts.

Facilitating Easy Maintenance

Custom shower floor drain covers facilitate easy cleaning and maintenance, helping to uphold high hygiene standards. The smooth surfaces and resistant materials prevent bacterial growth and make sanitization straightforward.

Enhancing Operational Efficiency

Implementing custom shower floor drain covers improves operational efficiency by ensuring smooth drainage and reducing maintenance needs. This efficiency helps avoid costly repairs and disruptions.

Environmental Considerations

Utilizing Recyclable Materials

Stainless steel is 100% recyclable, reducing waste and conserving resources. Choosing recyclable materials for shower floor drain covers aligns with sustainable practices, supporting hotels and resorts in their environmental efforts.

Implementing Sustainable Practices

Opting for durable and recyclable materials for shower floor drain covers supports sustainability efforts, minimizing environmental impact.

Compliance with Industry Standards

Meeting ISO Standards

Our custom shower floor drain covers meet ISO standards for quality and safety, ensuring they are reliable for high-end hospitality environments.

Ensuring ADA Compliance

Designing shower floor drain covers to comply with the Americans with Disabilities Act (ADA) ensures accessibility and safety for all guests, including those with disabilities.

Attaining NSF Certification

NSF certification indicates that our products meet stringent standards for public health protection and sanitation, ensuring suitability for hospitality settings.

Applications in Different Types of Hotels and Resorts

Enhancing Luxury Hotels

Luxury hotels benefit from custom shower floor drain covers offering both aesthetic appeal and superior functionality. High-end finishes and intricate designs enhance the bathroom’s look and feel, providing an upscale experience for guests.

Reflecting Boutique Hotels’ Unique Style

Boutique hotels can use custom designs to reflect their unique style and brand identity. Personalized patterns and finishes help create a distinct and memorable bathroom experience for guests.

Maintaining Resort Spas

Resort spas require efficient and hygienic drainage solutions to maintain a relaxing and clean environment. Custom shower floor drain covers ensure that water flows efficiently, preventing build-up or hygiene issues.

Improving Business Hotels’ Practicality

For business hotels, practicality and durability are key. Custom shower floor drain covers provide the robustness needed to withstand high usage while maintaining an elegant and professional appearance.

Innovative Design Features

Implementing Modular Design

Modular components ensure easy replacement and maintenance, minimizing downtime.

Including Integrated Filters

Integrated filters trap smaller debris, preventing clogs and ensuring smooth drainage. This feature is particularly beneficial in high-use environments like hotel showers.

Adjusting Heights

Adjustable height designs accommodate different floor levels and drainage needs, ensuring a perfect fit and optimal performance in any bathroom setup.

Adding Locking Mechanisms

Locking mechanisms prevent unauthorized removal, maintaining the integrity of the drainage system and enhancing security in public and private shower areas.

Customize Your Shower Floor Drain Covers from Our Factory

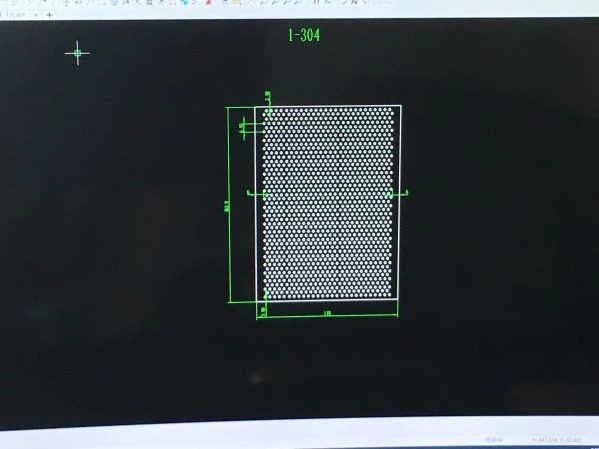

Overview of the Customization Process

Our customization process ensures each shower floor drain cover meets the unique requirements of our clients:

- Consultation: We start with a detailed consultation to understand your specific needs and preferences.

- Design: Our design team creates detailed plans based on your specifications, ensuring a perfect fit and optimal performance.

- Production: We utilize advanced manufacturing techniques to produce the customized shower floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

Benefits of Custom Solutions

Customizing shower floor drain covers provides several benefits:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance durability and performance.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

After-Sales Service

Reliable after-sales service includes:

- Technical Support: Our team of experts provides ongoing technical support to ensure optimal product performance.

- Maintenance Guidance: We offer detailed maintenance guides to help clients keep their shower floor drain covers in top condition.

- Replacement Parts: Quick access to replacement parts minimizes downtime and maintains operational efficiency.

- Customer Feedback: We actively seek and incorporate customer feedback to continually improve our products and services.

Contact Us

Enterprise customers interested in custom shower floor drain covers can contact us by submitting the form on our website. Our team stands ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.