The aerospace industry demands high-performance components that ensure efficiency, safety, and durability. Floor drain covers, often overlooked, are critical in maintaining hygiene and operational efficiency in aerospace facilities. This article explores the application, technical benefits, and manufacturing process of high-performance floor drain covers specifically designed for the aerospace industry. Additionally, it discusses after-sales services, environmental impact, and customization options tailored to the industry’s unique requirements.

Application of Perforated Floor Drain Covers in Aerospace Industry

Perforated floor drain covers are essential in aerospace facilities for several reasons. They ensure efficient drainage in areas such as hangars, maintenance bays, and production floors, preventing water accumulation that can lead to safety hazards and equipment damage. These covers also help maintain a clean and hygienic environment, which is crucial in aerospace settings where precision and cleanliness are paramount.

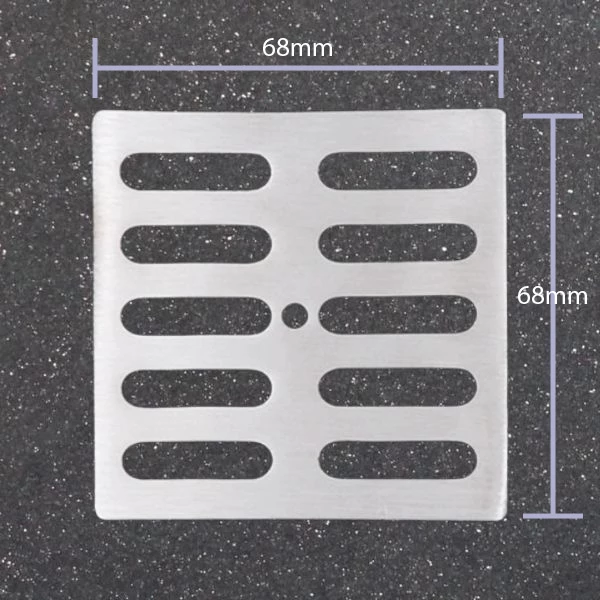

Stainless steel 304 perforated floor drain covers are particularly suited for the aerospace industry due to their durability, corrosion resistance, and ability to withstand heavy loads. Their design allows for efficient water flow while trapping debris, ensuring that the drainage systems remain unclogged and functional.

Technical Benefits of Floor Drain Covers

High-performance floor drain covers offer several technical benefits that are crucial in the aerospace industry:

- Corrosion Resistance: Stainless steel 304 is highly resistant to corrosion, making it ideal for environments exposed to chemicals and moisture.

- Durability: These covers can withstand heavy loads and impacts, ensuring long-term performance in high-traffic areas.

- Ease of Maintenance: Stainless steel is easy to clean and maintain, which is essential for maintaining high hygiene standards.

- Aesthetic Appeal: The sleek appearance of stainless steel adds a professional look to any facility.

- Customization: The ability to customize perforation patterns and sizes ensures optimal performance for specific applications.

Advanced Design Features for Aerospace Applications

In the aerospace industry, floor drain covers must meet stringent standards for safety, durability, and efficiency. Advanced design features include:

- Anti-Slip Surfaces: Ensuring safety in areas with high foot traffic by providing additional grip.

- High Load Capacity: Designed to handle the weight of heavy machinery and equipment commonly found in aerospace facilities.

- Chemical Resistance: Enhanced resistance to various chemicals used in aerospace manufacturing and maintenance processes.

- Precision Engineering: Custom perforation patterns that optimize drainage and debris capture, tailored to specific facility needs.

Compliance with Aerospace Industry Standards

Our floor drain covers comply with international aerospace industry standards, ensuring they meet regulatory requirements. This compliance includes:

- ISO Standards: Adherence to ISO standards for material quality and manufacturing processes.

- FAA Regulations: Meeting the Federal Aviation Administration’s requirements for safety and operational efficiency.

- NADCAP Certification: Ensuring processes meet the stringent quality control standards of the National Aerospace and Defense Contractors Accreditation Program.

Manufacturing Process of Floor Drain Covers in Our Factory

Our factory employs advanced manufacturing techniques to produce high-performance floor drain covers for the aerospace industry. The process includes:

- Material Selection: Using premium stainless steel 304 for its superior properties.

- Cutting and Shaping: Precision cutting and shaping using CNC machines to ensure accuracy and consistency.

- Perforation: Custom perforation patterns created using advanced CNC perforation techniques.

- Finishing: Options include brushed, polished, and matte finishes to suit specific requirements.

- Quality Control: Rigorous testing and inspection to ensure each product meets our high standards.

After-Sales Service

Our after-sales service ensures that clients receive ongoing support and maintenance for their floor drain covers. Services include:

- Technical Support: Expert assistance for installation, troubleshooting, and optimization.

- Maintenance Guidelines: Comprehensive guides to help clients maintain their floor drain covers effectively.

- Replacement Parts: Availability of spare parts to ensure minimal downtime and continuous operation.

- Customer Feedback: Actively seeking feedback to improve our products and services continuously.

Environmental Impact and Sustainability

We prioritize sustainability in our manufacturing processes. Our stainless steel 304 floor drain covers are:

- Recyclable: Made from recyclable materials, reducing environmental impact.

- Energy Efficient: Manufactured using energy-efficient processes to minimize carbon footprint.

- Long-Lasting: Designed for durability, reducing the need for frequent replacements and minimizing waste.

Customize Your Floor Drain Covers from Our Factory

Overview of the Customization Process

Our customization process provides tailored solutions to meet the specific requirements of aerospace industry clients:

- Consultation: We start with a thorough consultation to understand your needs and preferences.

- Design: Our design team creates detailed plans based on your specifications.

- Production: Using advanced manufacturing techniques, we produce customized floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

Benefits of Custom Solutions Tailored to Specific Aerospace Industry Requirements

Custom floor drain covers offer several benefits:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance the durability and performance of the covers.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team is ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.