Floor drain covers play a crucial role in maintaining the safety and hygiene of aquatic centers. Custom fabrication of these covers offers numerous advantages, catering to the specific needs and aesthetics of each facility.

Benefits of Custom Floor Drain Covers for Aquatic Centers

Custom floor drain covers provide several benefits for aquatic centers:

- Enhanced Safety: Custom covers can be designed with non-slip surfaces, reducing the risk of slips and falls. They can also be made with recessed edges to prevent tripping hazards.

- Improved Hygiene: Custom covers can be fabricated with antimicrobial materials, inhibiting the growth of bacteria and mold. This helps maintain a clean and healthy environment for swimmers.

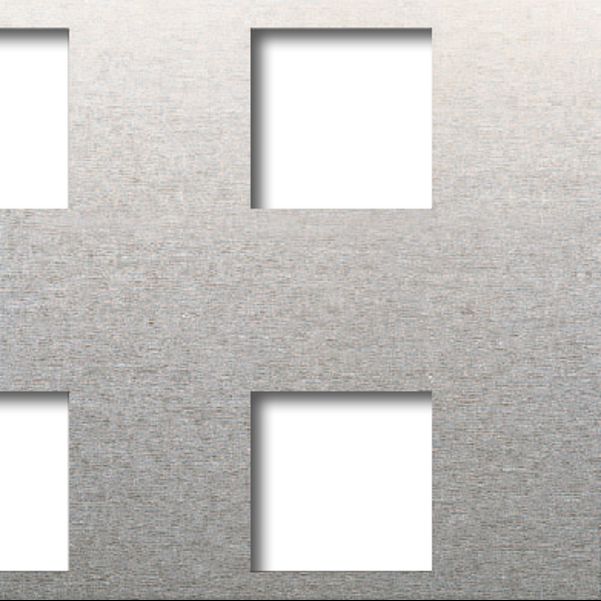

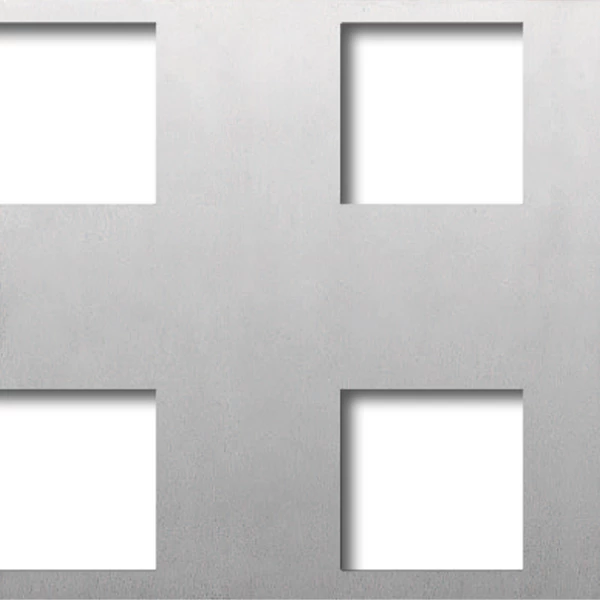

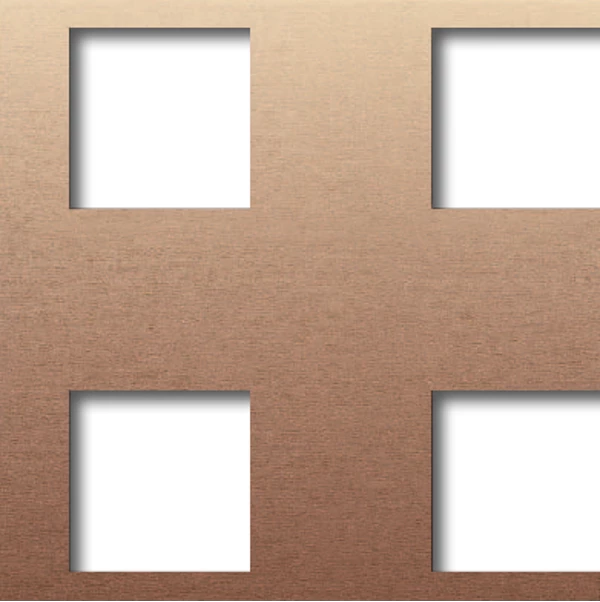

- Aesthetic Appeal: Custom covers can be designed to complement the overall design of the aquatic center, enhancing its visual appeal. They can be made in various colors, shapes, and sizes to match the facility’s décor.

- Durability: Custom covers are typically made from durable materials such as stainless steel or composite resins, ensuring longevity and resistance to wear and tear.

Materials and Design Considerations

The choice of materials and design for custom floor drain covers depends on several factors:

- Material: Stainless steel is a popular choice for its durability, corrosion resistance, and ease of cleaning. Composite resins offer lightweight and customizable options.

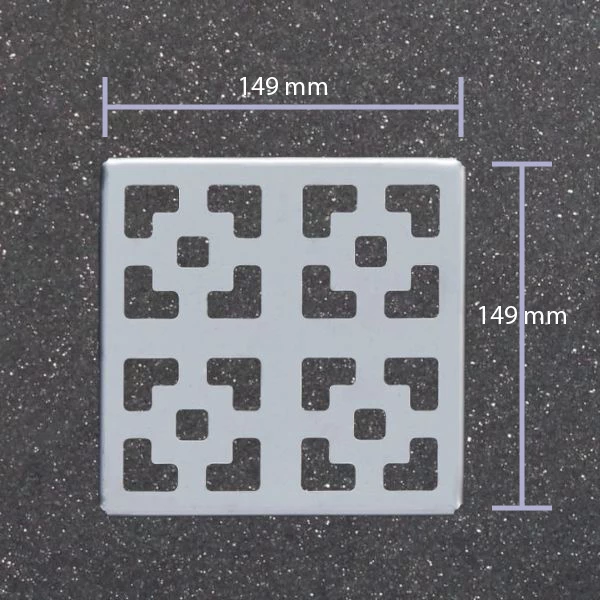

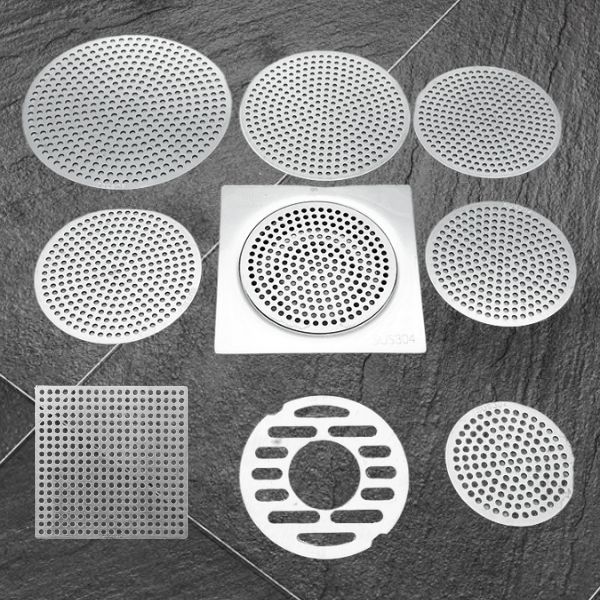

- Shape: Covers can be square, rectangular, or circular, depending on the drain size and location.

- Size: Covers should be sized appropriately to fit the drain opening securely.

- Surface: Non-slip surfaces are essential for safety, while recessed edges prevent tripping.

- Drainage: Covers should allow for efficient water drainage while preventing debris from entering the drain.

Fabrication Process

The fabrication process for custom floor drain covers involves several steps:

- Design: The design is finalized based on the material, shape, size, and surface requirements.

- Material Preparation: The chosen material is cut and shaped to the desired dimensions.

- Fabrication: The cover is fabricated using welding, molding, or other techniques, depending on the material.

- Finishing: The cover is polished, coated, or painted to enhance its appearance and durability.

- Quality Control: The finished cover is inspected to ensure it meets the specified requirements.

Installation and Maintenance of Custom Floor Drain Covers

Proper installation and maintenance are essential for the optimal performance of custom floor drain covers:

- Installation: Covers should be installed securely using appropriate fasteners.

- Maintenance: Covers should be regularly cleaned and inspected for any damage or wear.

- Replacement: Damaged or worn covers should be replaced promptly to maintain safety and hygiene.

Customize your Floor Drain Covers for Aquatic Centers

Custom fabrication of floor drain covers offers numerous benefits for aquatic centers, enhancing safety, hygiene, aesthetics, and durability. By considering the specific needs and design of each facility, custom covers can effectively protect swimmers from hazards, maintain a clean environment, and complement the overall visual appeal of the aquatic center.