Floor drain covers are essential components in automotive plants, ensuring cleanliness and safety by managing waste and preventing water accumulation. Automotive plants require robust and reliable drainage systems to maintain efficient operations. This article explores the application, technical benefits, specifications, and design considerations of floor drain covers, particularly focusing on the offerings of FILTERMFRS™ as a leading supplier.

Application of Perforated Floor Drain Cover in Automotive Plants

Perforated floor drain covers play a crucial role in automotive plants, where they manage the runoff from various processes, including washing, cooling, and general cleaning. These covers prevent debris from clogging the drainage systems, ensuring smooth water flow and maintaining sanitary conditions. In areas where fluids are frequently spilled or used, such as assembly lines, paint shops, and maintenance areas, high-quality drain covers are indispensable. They help in minimizing slip hazards, protecting equipment, and ensuring a safe working environment.

Technical Benefits of Floor Drain Cover

The technical benefits of using perforated floor drain covers in automotive plants are substantial:

- Corrosion Resistance: Stainless steel 304 offers excellent resistance to corrosion, essential in environments exposed to chemicals and moisture.

- Durability: The robust construction of stainless steel ensures that the drain covers can withstand heavy loads and impacts common in automotive plants.

- Hygiene: Stainless steel is easy to clean and does not harbor bacteria, making it ideal for maintaining high hygiene standards.

- Aesthetic Appeal: The sleek, professional look of stainless steel adds to the overall aesthetic of the facility, promoting a clean and organized appearance.

- Versatility: Perforated designs can be customized to suit specific drainage needs, ensuring optimal performance in various applications.

Technical Specifications of Floor Drain Cover

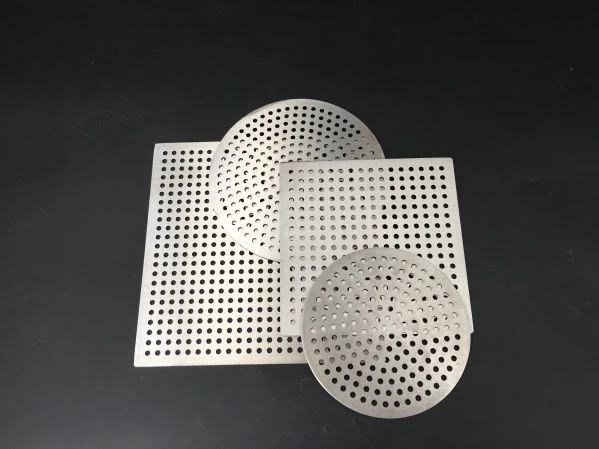

Our stainless steel 304 perforated floor drain covers are designed to meet the rigorous demands of automotive plants. Key specifications include:

- Thickness: 1mm to 2mm, customizable to specific requirements.

- Shape: Available in round and square shapes, with custom shapes also available.

- Diameter: Ranges from 30mm to 180mm, with options for non-standard sizes.

- Finish: Choose from brushed, polished, or matte finishes to suit your facility’s aesthetics.

- Perforation Patterns: Options include round holes, square holes, slotted holes, and custom patterns. For more information on optimizing perforation patterns, read this article Optimizing Perforation Patterns for Efficient Drain Covers.

These specifications ensure our floor drain covers not only meet but exceed the operational demands of automotive plants.

Design Considerations for Floor Drain Cover in Automotive Plants

Designing floor drain covers for automotive plants requires careful consideration of several factors to ensure functionality and efficiency:

- Load Capacity: The drain covers must withstand the weight of vehicles, machinery, and heavy equipment. Stainless steel 304 provides the necessary strength and durability.

- Slip Resistance: Incorporating anti-slip features in the design can enhance safety by preventing accidents caused by wet and slippery surfaces.

- Ease of Maintenance: The design should allow for easy removal and cleaning to maintain hygiene and prevent clogs.

- Chemical Resistance: The materials used must resist the corrosive effects of chemicals commonly used in automotive plants, such as cleaning agents and coolants.

- Customization: The ability to customize the size, shape, and perforation pattern ensures that the drain covers fit perfectly and perform optimally in different areas of the plant.

Integration with Existing Drainage Systems

Ensuring that the floor drain covers integrate seamlessly with existing drainage systems is crucial. Custom designs can match the exact dimensions and specifications of the current setup, minimizing the need for extensive modifications. This integration ensures that the installation process is smooth and that the covers function efficiently from the start.

Environmental Considerations

Sustainable manufacturing practices are increasingly important in today’s industrial landscape. Using stainless steel 304, which is recyclable and has a long lifespan, contributes to the sustainability of your operations. Additionally, by preventing leaks and managing waste effectively, high-quality floor drain covers can help automotive plants comply with environmental regulations and reduce their ecological footprint.

Choose FILTERMFRS™ as Your Floor Drain Cover Supplier

FILTERMFRS™ stands out as a premier supplier of stainless steel 304 perforated floor drain covers, offering unparalleled quality and service. Here are a few reasons to choose us:

- High-Quality Materials: We use premium stainless steel 304, ensuring durability and resistance to corrosion.

- Advanced Manufacturing: Our state-of-the-art manufacturing facilities guarantee precision and consistency in every product.

- Customization Options: We provide tailored solutions to meet the specific needs of your automotive plant, enhancing the functionality and aesthetic appeal of our products.

- Efficient Logistics: We have established robust logistics networks to ensure timely delivery across the globe.

- Compliance with Standards: Our products comply with international standards, ensuring they meet regulatory requirements worldwide.

- Excellent After-Sales Service: Our dedicated team offers ongoing technical support, maintenance guidance, and quick access to replacement parts, ensuring the longevity and efficiency of our products.

Customize Your Floor Drain Covers from Our Factory

Overview of the Customization Process

Our customization process is designed to provide tailored solutions that meet the specific requirements of our clients. Here’s an overview of the process:

- Consultation: We begin with a thorough consultation to understand your needs and preferences.

- Design: Our design team creates detailed plans based on your specifications.

- Production: Using advanced manufacturing techniques, we produce the customized floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

Benefits of Custom Solutions Tailored to Export

Customizing floor drain covers for export offers several benefits:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance the durability and performance of the covers.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team is ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.