Dairy production facilities require specialized equipment to maintain high standards of hygiene and operational efficiency. One critical component in these facilities is the floor drain cover. Bespoke floor drain covers are tailored to meet the unique needs of dairy production environments, ensuring optimal performance, durability, and cleanliness. This article explores the technical benefits, design considerations, manufacturing process, and after-sales services for bespoke floor drain covers in dairy production facilities.

Technical Benefits of Bespoke Floor Drain Covers

Bespoke floor drain covers offer numerous technical benefits that are essential for dairy production facilities:

- Corrosion Resistance: Stainless steel 304 is the preferred material for bespoke floor drain covers due to its exceptional resistance to corrosion. This ensures long-term durability even in environments exposed to cleaning agents and dairy by-products.

- Hygiene: The smooth, non-porous surface of stainless steel is easy to clean and disinfect, helping maintain high hygiene standards. Perforation patterns can be optimized to prevent the buildup of debris and facilitate easy cleaning.

- Load Bearing Capacity: Custom-designed floor drain covers can be engineered to withstand the heavy loads typical in dairy production facilities, including the weight of machinery and foot traffic.

- Efficient Drainage: Perforation patterns can be customized to ensure efficient drainage, preventing water accumulation and minimizing slip hazards. This is crucial in maintaining a safe working environment.

Design Considerations for Bespoke Floor Drain Covers in Dairy Production Facilities

Designing floor drain covers for dairy production facilities involves several key considerations to ensure they meet the specific needs of the environment:

- Material Selection: Stainless steel 304 is the material of choice due to its durability, corrosion resistance, and ease of cleaning. It is also non-reactive with dairy products and cleaning agents.

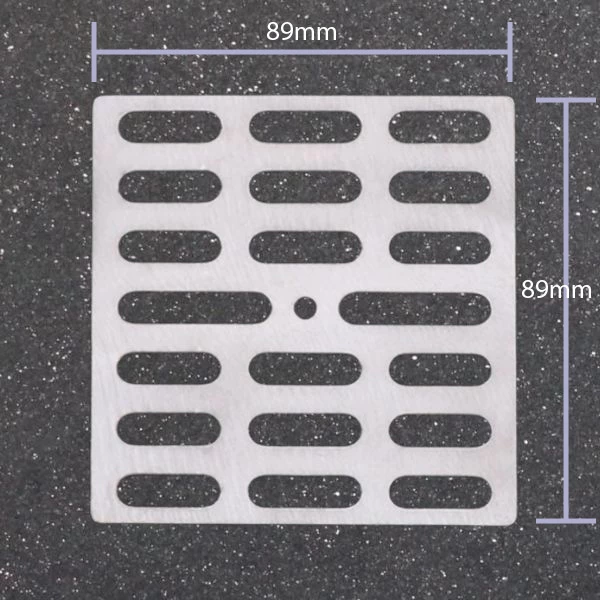

- Perforation Patterns: The design of perforation patterns is critical for ensuring efficient drainage and preventing clogging. Options include round holes, square holes, slotted holes, and custom patterns tailored

Bespoke Floor Drain Covers for Dairy Production Facilities

Dairy production facilities require specialized equipment to maintain high standards of hygiene and operational efficiency. One critical component in these facilities is the floor drain cover. Bespoke floor drain covers are tailored to meet the unique needs of dairy production environments, ensuring optimal performance, durability, and cleanliness. This article explores the technical benefits, design considerations, manufacturing process, and after-sales services for bespoke floor drain covers in dairy production facilities.

Technical Benefits of Bespoke Floor Drain Covers

Bespoke floor drain covers offer numerous technical benefits that are essential for dairy production facilities:

- Corrosion Resistance: Stainless steel 304 is the preferred material for bespoke floor drain covers due to its exceptional resistance to corrosion. This ensures long-term durability even in environments exposed to cleaning agents and dairy by-products.

- Hygiene: The smooth, non-porous surface of stainless steel is easy to clean and disinfect, helping maintain high hygiene standards. Perforation patterns can be optimized to prevent the buildup of debris and facilitate easy cleaning.

- Load Bearing Capacity: Custom-designed floor drain covers can be engineered to withstand the heavy loads typical in dairy production facilities, including the weight of machinery and foot traffic.

- Efficient Drainage: Perforation patterns can be customized to ensure efficient drainage, preventing water accumulation and minimizing slip hazards. This is crucial in maintaining a safe working environment.

Design Considerations for Bespoke Floor Drain Covers in Dairy Production Facilities

Designing floor drain covers for dairy production facilities involves several key considerations to ensure they meet the specific needs of the environment:

- Material Selection: Stainless steel 304 is the material of choice due to its durability, corrosion resistance, and ease of cleaning. It is also non-reactive with dairy products and cleaning agents.

- Perforation Patterns: The design of perforation patterns is critical for ensuring efficient drainage and preventing clogging. Options include round holes, square holes, slotted holes, and custom patterns tailored to specific requirements. For more information on optimizing perforation patterns, read this article:

Optimizing Perforation Patterns for Efficient Drain Covers. - Size and Shape: The size and shape of the drain covers should match the specific dimensions of the drainage system in the facility. Custom sizes and shapes ensure a perfect fit and optimal performance.

- Finish: The finish of the drain covers should be smooth and non-porous to prevent bacterial growth and facilitate easy cleaning. Options include brushed, polished, and matte finishes.

Enhancing Safety with Bespoke Floor Drain Covers

Safety is a paramount concern in dairy production facilities, and bespoke floor drain covers play a crucial role in enhancing safety:

- Anti-Slip Surface: Custom drain covers can include anti-slip surfaces to prevent slips and falls, especially in areas where liquids are frequently present.

- Seamless Integration: Custom-designed covers ensure seamless integration with the facility’s flooring, reducing tripping hazards and ensuring a smooth, safe surface.

- Compliance with Standards: Bespoke covers can be designed to meet specific safety standards and regulations, ensuring the facility remains compliant with industry requirements.

Optimizing Hygiene with Bespoke Floor Drain Covers

Maintaining high hygiene standards is critical in dairy production facilities. Bespoke floor drain covers can be optimized to enhance hygiene:

- Smooth Surface: Stainless steel 304 provides a smooth, non-porous surface that is easy to clean and disinfect.

- Debris Prevention: Customized perforation patterns can effectively prevent debris from clogging the drainage system, maintaining a clean and sanitary environment.

- Easy Maintenance: Custom designs can include features that facilitate easy removal and maintenance of the drain covers, ensuring they remain in optimal condition.

Manufacturing Process of Bespoke Floor Drain Covers in Our Factory

Our factory employs advanced manufacturing techniques to produce high-quality bespoke floor drain covers. The process involves:

- Consultation and Design: We begin with a thorough consultation to understand the client’s requirements. Our design team creates detailed plans based on the specifications provided.

- Material Selection: We use premium stainless steel 304 for its durability, corrosion resistance, and hygiene benefits.

- Cutting and Perforation: Advanced CNC machines are used to cut the stainless steel sheets to the required size and create the specified perforation patterns.

- Finishing: The covers are then finished to the client’s specifications, whether brushed, polished, or matte.

- Quality Control: Each cover undergoes rigorous quality checks to ensure it meets our high standards before being shipped to the client.

After-Sales Service

We provide comprehensive after-sales services to ensure our clients are satisfied with their bespoke floor drain covers:

- Technical Support: Our team offers ongoing technical support to help clients with any issues or questions they may have.

- Maintenance Advice: We provide detailed maintenance guides to help clients keep their drain covers in optimal condition.

- Replacement Parts: We offer quick access to replacement parts to minimize downtime and maintain operational efficiency.

Order Bespoke Floor Drain Covers from Our Factory

Overview of the Customization Process

Our customization process is designed to provide tailored solutions that meet the specific requirements of dairy production facilities. The process includes:

- Consultation: We begin with a thorough consultation to understand your needs and preferences.

- Design: Our design team creates detailed plans based on your specifications.

- Production: Using advanced manufacturing techniques, we produce the customized floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

The Benefits of Custom Solutions Tailored to Specific Dairy Production Facilities Requirements

Custom solutions offer several benefits:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance the durability and performance of the covers.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

Contact Us

Enterprise customers interested in bespoke floor drain covers can contact us by submitting the form on our website. Our team is ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.