Floor drain covers are crucial components in airport terminals, ensuring efficient drainage and maintaining cleanliness and safety in high-traffic areas. As airports expand and modernize, the demand for durable, high-quality floor drain covers in bulk has grown significantly. This article explores the technical benefits, specifications, design considerations, and manufacturing processes of floor drain covers, tailored specifically for airport terminals. Additionally, it highlights the customization options available to meet the unique needs of these facilities.

Technical Benefits of Floor Drain Covers

Floor drain covers offer several technical benefits, making them indispensable in airport terminals:

- Efficient Drainage: High-quality floor drain covers facilitate efficient water drainage, preventing water accumulation and reducing slip hazards.

- Durability: Made from robust materials like stainless steel 304, these covers withstand heavy foot traffic, luggage trolleys, and cleaning equipment.

- Corrosion Resistance: Stainless steel 304 is highly resistant to corrosion, ensuring long-lasting performance even in wet environments.

- Hygiene: The smooth surface of stainless steel makes cleaning easy, maintaining high hygiene standards essential for public spaces like airports.

- Aesthetic Appeal: Sleek and modern designs of floor drain covers enhance the overall aesthetic of the terminal.

Technical Specifications of Floor Drain Covers

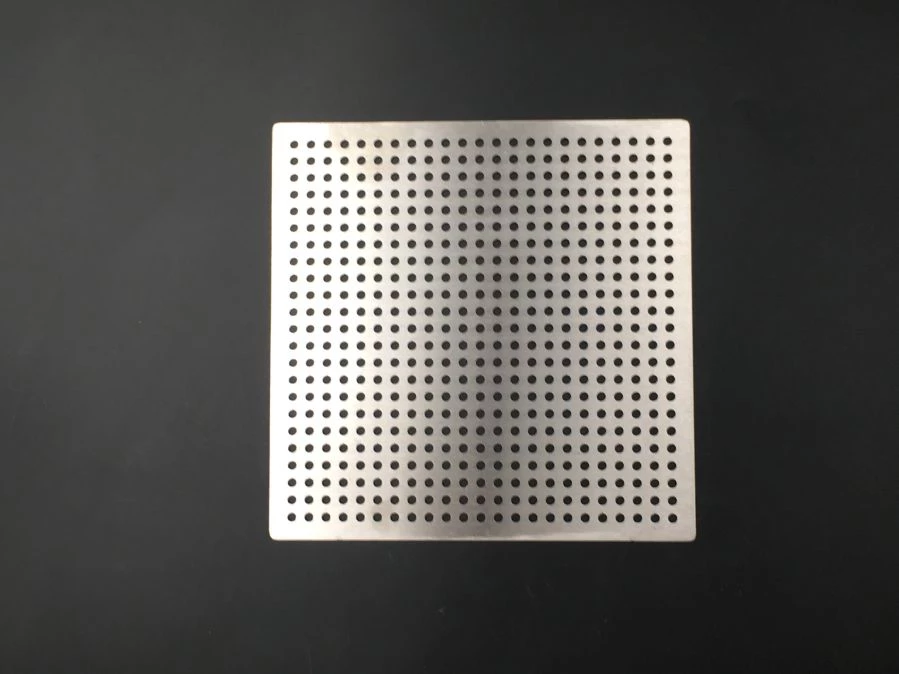

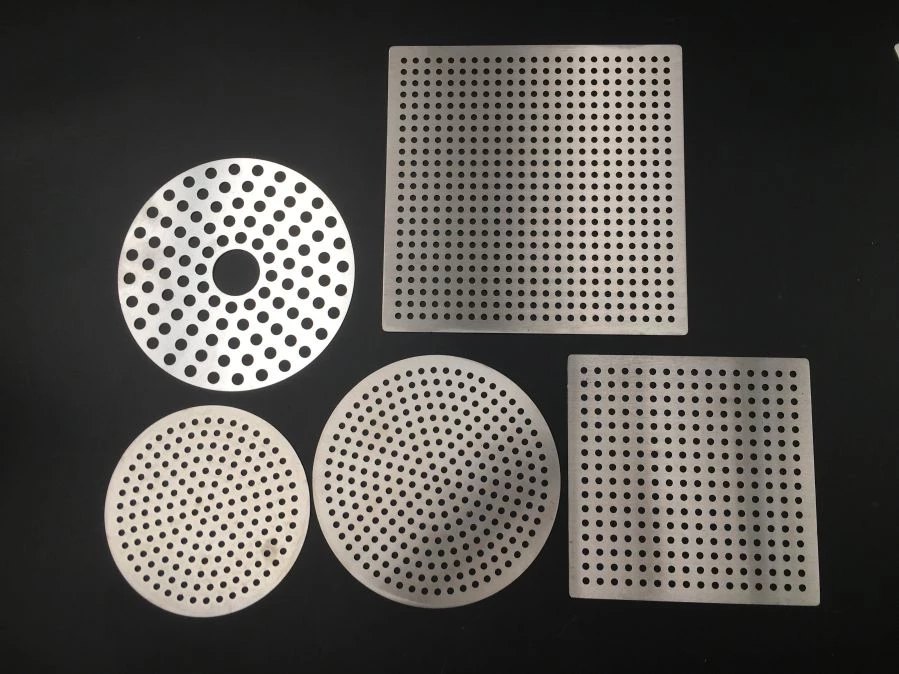

Our stainless steel 304 perforated floor drain covers are designed to meet the demanding requirements of airport terminals. Key specifications include:

- Thickness: 1mm to 2mm, customizable to specific needs.

- Shape: Available in round and square shapes, with custom shapes also available.

- Diameter: Ranges from 30mm to 180mm, with options for non-standard sizes.

- Finish: Brushed, polished, or matte finishes to suit different aesthetic preferences.

- Perforation Patterns: Options include round holes, square holes, slotted holes, and custom patterns. For more information on optimizing perforation patterns, read this article Optimizing Perforation Patterns for Efficient Drain Covers.

These specifications ensure that our floor drain covers meet the functional and aesthetic requirements of modern airport terminals.

Design Considerations for Floor Drain Covers in Airport Terminals

Designing floor drain covers for airport terminals involves several considerations to ensure they meet the unique challenges of these environments:

- Load-Bearing Capacity: Drain covers must support heavy loads, including foot traffic and wheeled luggage.

- Slip Resistance: Covers should feature anti-slip surfaces to prevent accidents, especially in areas prone to wet conditions.

- Ease of Maintenance: Design should facilitate easy removal and cleaning to maintain hygiene standards.

- Custom Fit: Drain covers should fit perfectly within the designated areas to ensure efficient drainage and avoid tripping hazards.

- Aesthetic Integration: The design should complement the architectural and interior design of the terminal.

Bulk Purchasing Advantages for Airport Terminals

Bulk purchasing of floor drain covers offers several advantages for airport terminals:

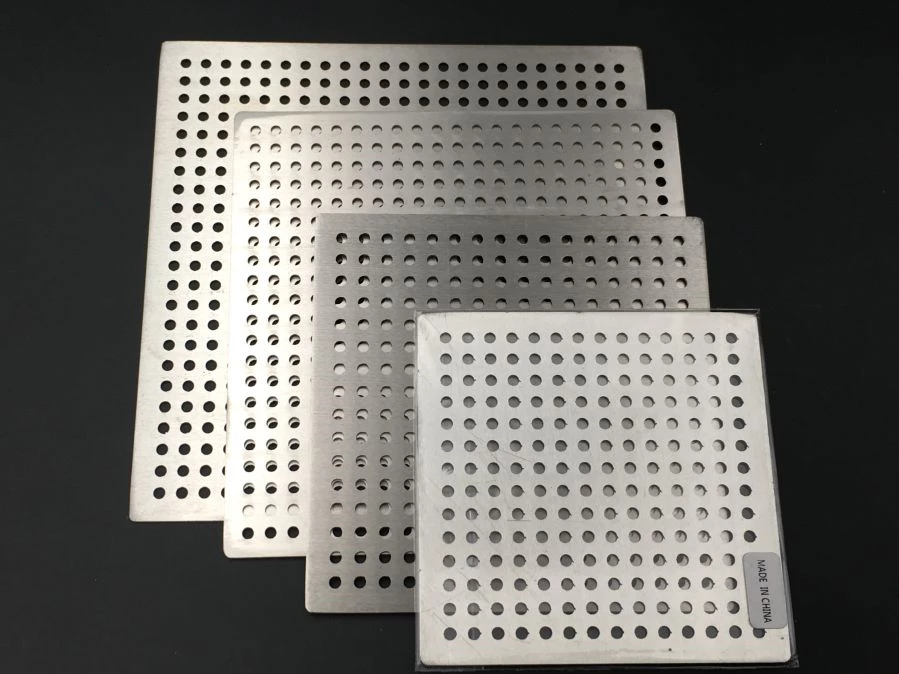

- Cost Efficiency: Buying in bulk reduces the unit cost, offering significant savings for large-scale projects.

- Consistent Quality: Bulk orders ensure consistent quality across all drain covers, maintaining uniform standards throughout the terminal.

- Streamlined Logistics: Coordinating a single bulk shipment simplifies logistics and reduces transportation costs.

- Timely Availability: Bulk purchasing ensures that all required drain covers are available when needed, avoiding delays in construction or renovation projects.

Supply Chain Management for Bulk Floor Drain Covers

Effective supply chain management is crucial when dealing with bulk orders for floor drain covers:

- Inventory Control: Maintaining optimal inventory levels to meet demand without overstocking.

- Supplier Relationships: Building strong relationships with reliable suppliers to ensure timely and consistent deliveries.

- Quality Assurance: Implementing strict quality control measures to ensure all products meet the required standards.

- Logistics Coordination: Efficiently managing the transportation and storage of bulk orders to minimize delays and costs.

- Cost Management: Monitoring and controlling costs throughout the supply chain to maximize savings.

Manufacturing Process of Floor Drain Covers in Our Factory

Our manufacturing process for stainless steel 304 perforated floor drain covers involves several key steps to ensure high quality and precision:

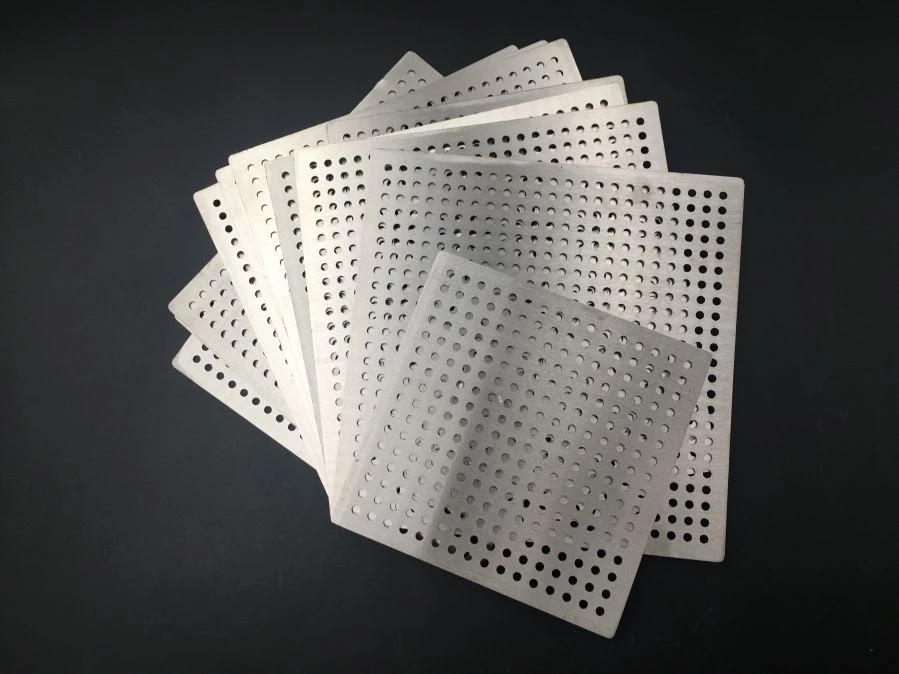

- Material Selection: We use premium-grade stainless steel 304, known for its durability and corrosion resistance.

- Cutting and Shaping: Advanced CNC machines cut and shape the metal sheets into the required dimensions and designs.

- Perforation: Precision perforation is achieved using state-of-the-art machinery, ensuring uniform hole patterns and sizes.

- Finishing: The covers are finished with brushed, polished, or matte surfaces, as per client specifications.

- Quality Control: Rigorous quality checks are conducted at every stage to ensure the final product meets the highest standards.

- Packaging: The covers are securely packaged to prevent damage during transportation and storage.

Our After-Sales Service

We offer comprehensive after-sales service to ensure our clients receive the support they need:

- Technical Support: Our experts provide ongoing technical assistance to address any issues or queries.

- Maintenance Advice: We offer detailed maintenance guides to help clients keep their floor drain covers in optimal condition.

- Replacement Parts: Quick access to replacement parts ensures minimal downtime and continuous operation.

- Customer Feedback: We actively seek customer feedback to improve our products and services continually.

Customize Your Floor Drain Covers from Our Factory

Overview of the Customization Process

Our customization process is designed to provide tailored solutions that meet the specific requirements of airport terminals. Here’s an overview:

- Consultation: We begin with a thorough consultation to understand your needs and preferences.

- Design: Our design team creates detailed plans based on your specifications.

- Production: Using advanced manufacturing techniques, we produce the customized floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

The Benefits of Custom Solutions Tailored to Specific Airport Terminal Requirements

Customizing floor drain covers for airport terminals offers several benefits:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance the durability and performance of the covers.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team is ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.