Floor drain covers are essential components in chemical processing plants, playing a critical role in maintaining hygiene and safety standards. These facilities require robust, corrosion-resistant drainage solutions to handle harsh chemicals and heavy usage. This article explores the importance of floor drain cover dealers, the technical specifications and design considerations for these covers, and the customization options available to meet specific needs.

Floor Drain Cover Dealers

Floor drain cover dealers specialize in providing high-quality, durable solutions tailored to the unique requirements of chemical processing plants. These dealers offer a wide range of products designed to withstand the harsh conditions found in such facilities. By partnering with reputable dealers, chemical processing plants can ensure they receive reliable and efficient drainage solutions.

Key aspects that reputable floor drain cover dealers focus on include:

- Material Quality: Dealers prioritize high-grade materials, such as stainless steel 304, known for its corrosion resistance and durability.

- Customization Options: Offering custom sizes, shapes, and perforation patterns to meet specific facility requirements.

- Compliance: Ensuring all products meet industry standards and regulations for safety and performance.

- Technical Support: Providing ongoing support and maintenance services to ensure long-term functionality.

Technical Specifications of Floor Drain Covers

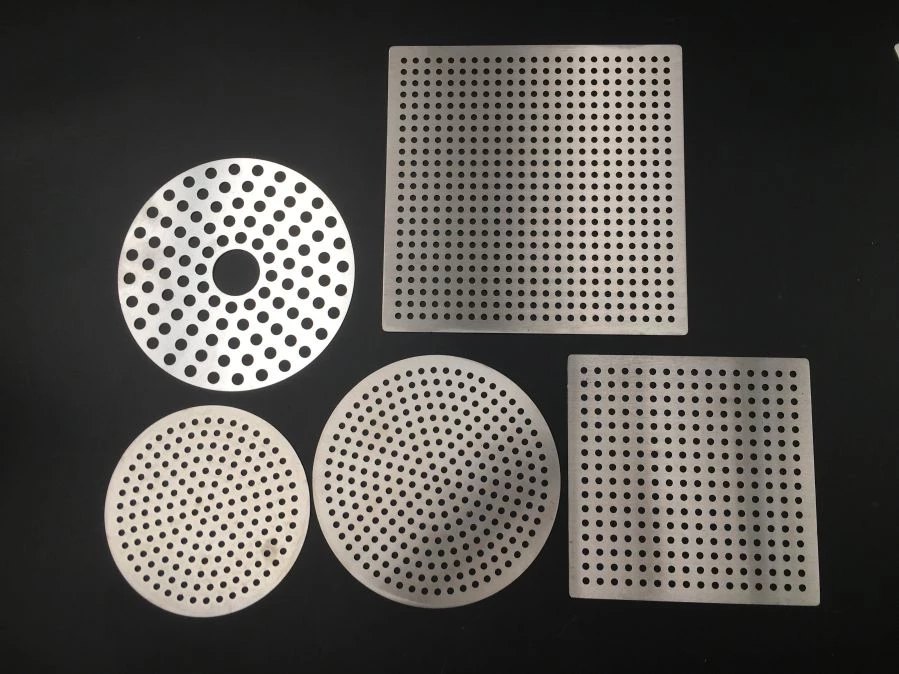

Our stainless steel 304 perforated floor drain covers are designed to meet the stringent demands of chemical processing plants. Key technical specifications include:

- Thickness: 1mm to 2mm, customizable to specific requirements.

- Shape: Available in round and square shapes, with custom shapes also available.

- Diameter: Ranges from 30mm to 180mm, with options for non-standard sizes.

- Finish: Choose from brushed, polished, or matte finishes to suit your facility’s aesthetics.

- Perforation Patterns: Options include round holes, square holes, slotted holes, and custom patterns. For more information on optimizing perforation patterns, read this article:

Optimizing Perforation Patterns for Efficient Drain Covers.

These specifications ensure our floor drain covers are robust, durable, and capable of handling the harsh conditions in chemical processing plants.

Design Considerations for Floor Drain Covers in Chemical Processing Plants

Designing floor drain covers for chemical processing plants involves several critical considerations:

- Chemical Resistance: Materials must withstand exposure to a variety of chemicals without degrading.

- Load-Bearing Capacity: Drain covers should support the weight of heavy equipment and foot traffic.

- Hygiene: Easy-to-clean designs are essential to maintain high hygiene standards.

- Safety: Anti-slip surfaces and secure fittings help prevent accidents and ensure safety.

- Flow Rate: Perforation patterns must ensure efficient drainage to handle large volumes of liquid.

Innovations in Floor Drain Cover Technology

Recent advancements in floor drain cover technology have led to the development of more efficient and durable products. Innovations include:

- Enhanced Perforation Techniques: Improved methods for creating precise perforations that enhance drainage efficiency.

- Composite Materials: Combining different materials to enhance strength, corrosion resistance, and longevity.

- Smart Drain Covers: Integration of sensors to monitor drainage performance and detect blockages or leaks in real-time.

Partnering with Floor Drain Cover Experts

Collaborating with experts in the field can provide significant advantages for chemical processing plants. Expert dealers offer:

- In-Depth Knowledge: Extensive understanding of industry requirements and standards.

- Tailored Solutions: Ability to provide customized designs and materials that meet specific operational needs.

- Quality Assurance: Commitment to delivering high-quality products that meet rigorous testing and certification standards.

- Comprehensive Service: From initial consultation and design to installation and ongoing maintenance support.

Find Floor Drain Cover Dealers

Finding the right floor drain cover dealer involves several steps:

- Research: Look for dealers with a strong reputation and positive customer reviews.

- Product Range: Ensure they offer a wide selection of floor drain covers in various designs and materials.

- Customization Capabilities: Check if they provide custom solutions tailored to your specific needs.

- Technical Support: Confirm they offer technical support and maintenance services.

- Pricing and Terms: Compare pricing, delivery times, and warranty options from multiple dealers.

Customize Your Floor Drain Cover from Our Factory

Overview of the Customization Process

Our customization process is designed to provide tailored solutions that meet the specific requirements of chemical processing plants. Here’s an overview of the process:

- Consultation: We begin with a thorough consultation to understand your needs and preferences.

- Design: Our design team creates detailed plans based on your specifications.

- Production: Using advanced manufacturing techniques, we produce the customized floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

Benefits of Custom Solutions Tailored to Chemical Processing Plants

Customizing floor drain covers for chemical processing plants offers several benefits:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance the durability and performance of the covers.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team is ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.