The world of commercial design demands precision and functionality. Every detail matters, from the selection of materials to the intricate design of individual components. Custom drain covers offer advantages over standard drain covers in terms of hygiene, safety and visual harmony. This article explores topics relevant to drain cover manufacturers, demonstrating the use of laser cutting and CNC machining in practical custom solutions.

The Evolution of Drain Cover Design

Drain covers have evolved from mere functional components to integral elements of interior design. Businesses, especially those seeking to cultivate a distinct brand identity or elevate the customer experience, recognize the importance of aesthetics. This shift in perspective has fueled a growing demand for customized drain covers that seamlessly blend with the environment, enhancing both functionality and visual appeal.

The Importance of Choosing the Right Drain Cover Manufacturer

Selecting the ideal manufacturer is critical to any custom drain cover project. This choice dictates the quality, durability, and aesthetic outcome of the final product. Here are key attributes to consider:

- Experience and Expertise: A reputable manufacturer boasts years of experience in crafting custom drain covers. This expertise encompasses a deep understanding of material properties, fabrication techniques, and the specific demands of various commercial applications. They understand the complexities of achieving a perfect fit, ensuring proper drainage, and maintaining long-term performance.

- Design Capabilities: The ability to translate client visions into functional and visually appealing designs is essential. Manufacturers should have skilled designers or collaborate with architects and interior designers to create bespoke solutions. This collaboration ensures a perfect fit within the overall design scheme, transforming the drain cover from a utilitarian component to a seamless part of the visual landscape.

- Manufacturing Prowess: A robust manufacturing facility equipped with cutting-edge machinery and skilled labor is paramount. This ensures precision and accuracy in every stage of the production process. Manufacturers should be able to handle complex designs, intricate patterns, and customized specifications, delivering high-quality products. They should be well-versed in the latest fabrication techniques, such as laser cutting, to achieve intricate designs with precision.

- Quality Assurance: A commitment to rigorous quality control is non-negotiable. Regular inspections and testing throughout the manufacturing process ensure that every drain cover meets the highest standards. These measures guarantee durability, reliability, and consistent quality.

- Customer-Centric Approach: Effective communication and responsiveness to client needs are critical. A reliable manufacturer will collaborate closely with clients throughout the design and production process. They will address concerns and ensure a smooth, seamless experience.

Tailoring Solutions: The Advantages of Custom Drain Covers

While standard drain covers offer some functionality, custom-designed solutions cater to the unique demands of commercial spaces. Here are key advantages of working with drain cover manufacturers:

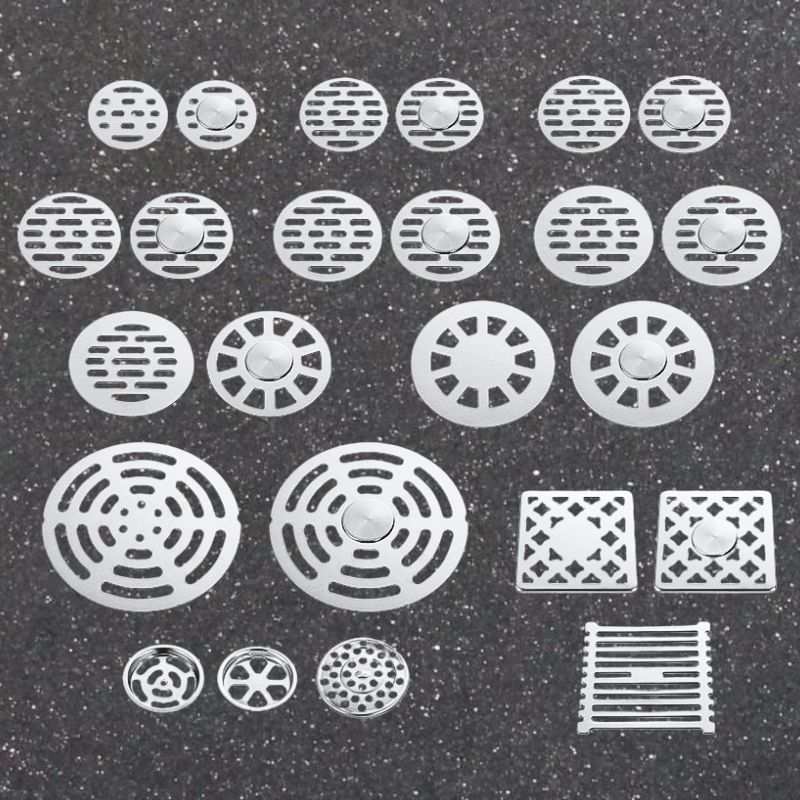

- Size and Shape Customization: Custom drain covers can be precisely tailored to fit any size and shape of drain opening, ensuring a seamless fit within the surrounding floor. This is crucial in areas with complex floor layouts or unique design elements.

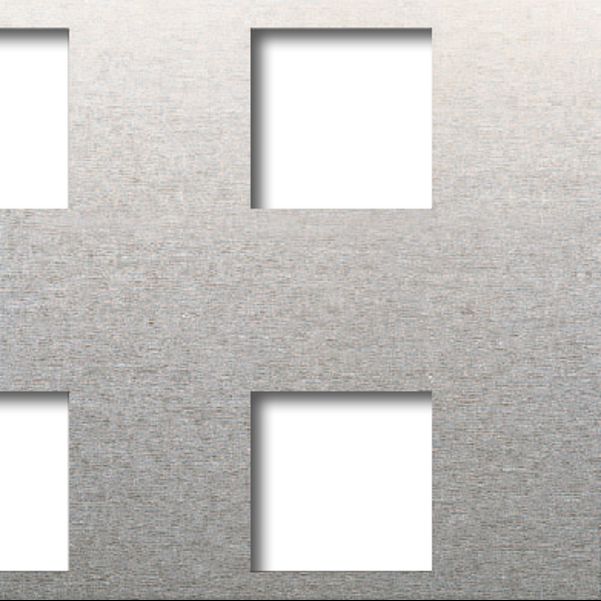

- Design Versatility: Custom drain covers offer endless design possibilities. From subtle patterns and finishes to bold, eye-catching designs, manufacturers work with clients to create covers that complement the overall aesthetic of the space. This design flexibility allows for seamless integration, enhancing the visual harmony of the environment.

- Functional Enhancements: Custom drain covers can incorporate functional elements like built-in traps or integrated drainage channels to improve water flow and prevent clogging. These features contribute to improved hygiene and efficiency, ensuring smooth operation and a clean, safe environment.

The Precision of Laser-Cut Drain Covers

Laser cutting technology revolutionizes drain cover manufacturing. It offers unparalleled precision and control, enabling the creation of intricate designs and complex shapes. This technology allows for:

- Intricate Detail: Laser cutting allows for the creation of intricate patterns and designs, adding a unique and stylish touch to drain covers.

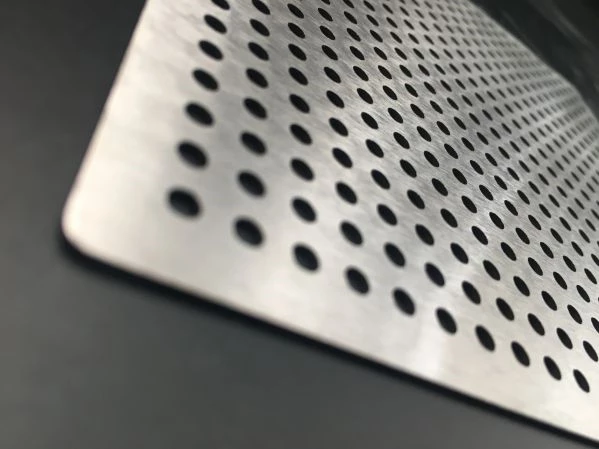

- Clean Edges: Laser-cut edges are smooth and precise, eliminating the need for additional finishing. This contributes to a cleaner aesthetic and enhances durability.

- Efficient Production: Laser cutting streamlines the manufacturing process, enabling faster production times and greater accuracy.

Understanding the Manufacturing Process:

The process of creating a custom drain cover typically involves the following steps:

- Initial Consultation: The manufacturer works closely with the client to understand their needs, design preferences, and the specific requirements of the project.

- Design Development: Skilled designers translate client visions into detailed CAD drawings, ensuring precision and accuracy.

- Prototyping: To ensure client satisfaction and address any necessary adjustments, manufacturers often create prototypes before moving into full-scale production. This allows for iterative refinements and ensures the final product aligns with the client’s expectations.

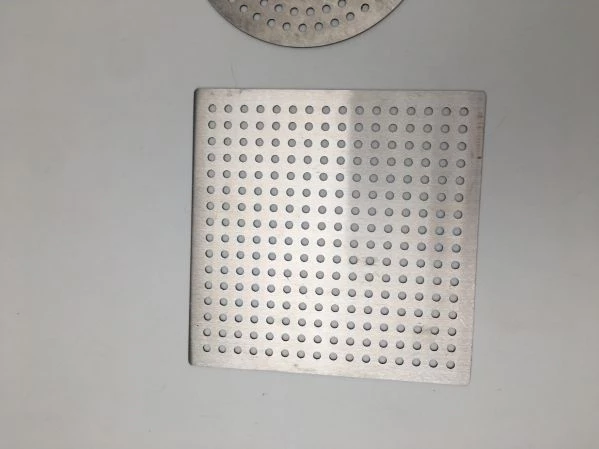

- CNC Machining: The process begins with CNC machining. This advanced technology shapes the raw material (typically stainless steel) into the desired shape and size.

- Laser Cutting: Laser cutting is then used to create the intricate designs and patterns that define the final look of the drain cover. This precise process allows for complex shapes and details with exceptional accuracy.

- Finishing: After laser cutting, the drain cover undergoes a final finishing process. This may involve sanding, polishing, or applying protective coatings to enhance the aesthetics and durability of the product.

- Quality Control: Throughout the process, rigorous quality checks are performed to ensure every component meets the highest standards. This commitment to quality guarantees the durability, reliability, and aesthetic appeal of the finished product.

- Delivery: Once complete, the custom drain covers are packaged and shipped to the client, ready for installation.

Elevating Commercial Spaces: The Role of Custom Drain Cover Manufacturers

Custom drain covers are not merely functional elements; they are design elements that contribute to a positive customer experience. By enhancing the visual appeal, hygiene, and safety of a space, they enhance the overall impression of a commercial establishment. This is where manufacturers play a vital role.

Drain cover manufacturers leverage their expertise in materials, design, and manufacturing to provide custom solutions. They elevate commercial spaces, creating environments that are not only functional but also visually appealing. Their commitment to quality and customer satisfaction ensures that every project is a success, contributing to a clean, safe, and aesthetically pleasing environment.

As the world of commercial design continues to evolve, the demand for custom drain covers will only increase. Manufacturers who embrace innovation and prioritize client needs will play a crucial role in shaping the future of commercial spaces.

Customize your Floor Drain Covers from our factory

We specialize in crafting custom drain covers that meet the unique demands of your commercial projects. Our commitment to quality, precision, and customer satisfaction makes us the ideal partner for elevating your spaces.

Material and Design Flexibility

We believe in offering our clients a wide range of options to suit their specific needs.

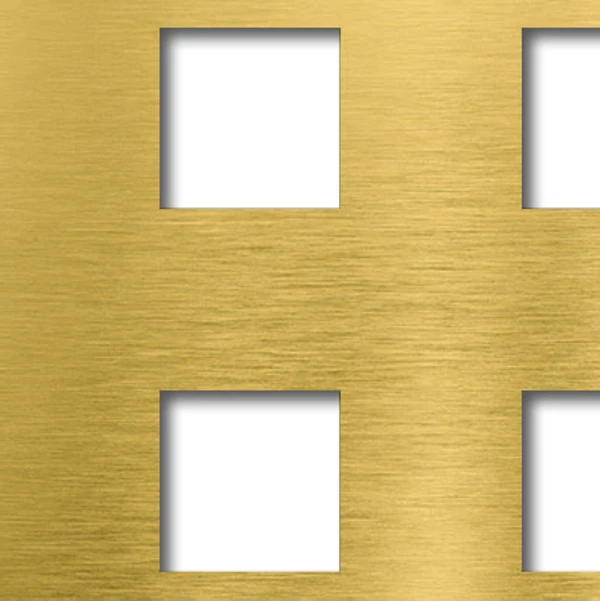

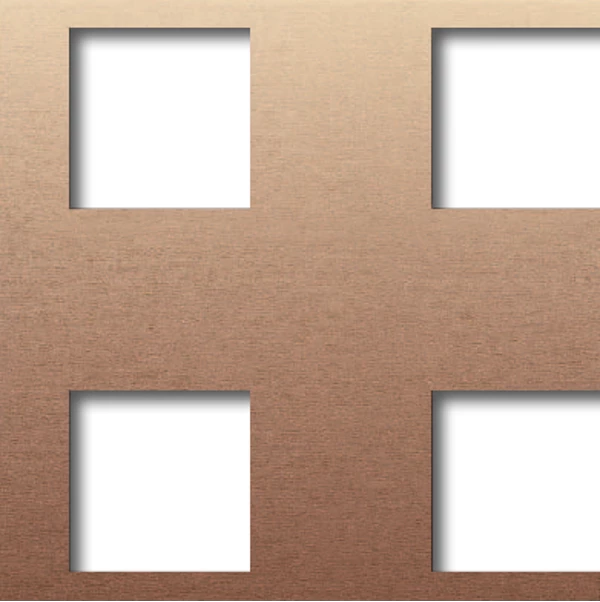

- Material Selection: We utilize premium-grade stainless steel for its durability, corrosion resistance, and aesthetic appeal.

- Thickness: We offer customizable thickness options, ranging from 1mm to 2mm, to meet varying load-bearing requirements.

- Shape and Size: From round to square and everything in between, we tailor the shape and size of your drain covers to fit your exact specifications. Diameters range from 30mm to 180mm, ensuring a seamless fit for any drain opening.

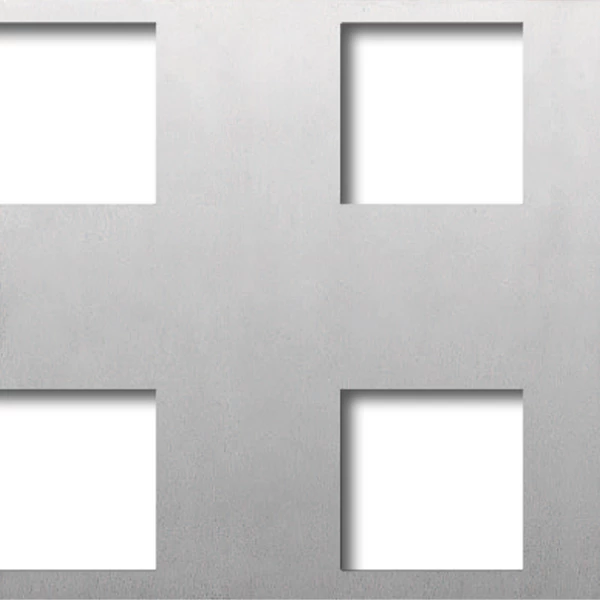

- Laser-Cut Designs: Our state-of-the-art laser cutting technology allows us to create intricate patterns and designs, adding a touch of elegance and sophistication to your drain covers.

Streamlined Manufacturing Process

Our manufacturing process is designed for efficiency and precision. We leverage advanced technology and skilled craftsmanship to deliver exceptional results.

- CNC Machining: We utilize CNC machining to precisely cut and shape the stainless steel, ensuring accuracy and consistency.

- Laser Cutting: Our laser cutting technology creates intricate designs and patterns with unparalleled precision, resulting in smooth, clean edges and a refined finish.

- Quality Control: Throughout every stage of production, our team conducts rigorous quality checks to guarantee that each drain cover meets our stringent standards.

After-sales Service

We are committed to providing exceptional service even after your order is complete. Our dedicated team is here to address any questions or concerns you may have. We value your feedback and strive to build long-lasting relationships with our clients.

Contact Us

Ready to elevate your commercial spaces with custom-designed drain covers? Contact us today to discuss your project requirements and discover the endless possibilities. Our team of experts is here to guide you through every step of the process, from design conception to final production.

Let us help you create drain covers that are not only functional but also visually stunning, seamlessly blending into your design aesthetic and enhancing the overall appeal of your space.