In electronics manufacturing, maintaining a clean and safe environment is critical. Floor drain covers play a significant role in ensuring that facilities remain hygienic and free from contaminants. Innovative floor drain covers, specifically designed for electronics manufacturing, offer numerous benefits in terms of design, functionality, and sustainability. This article will explore their application, technical benefits, design considerations, and customization options.

Application of Perforated Innovative Floor Drain Covers in Electronics Manufacturing

Perforated floor drain covers are essential in electronics manufacturing due to the need for precision and cleanliness. These covers prevent debris and contaminants from entering the drainage system while allowing efficient water flow. The use of stainless steel 304 perforated covers ensures durability and corrosion resistance, crucial for environments exposed to various chemicals and cleaning agents.

In cleanrooms and controlled environments, these drain covers help maintain the required standards by efficiently managing waste and preventing the buildup of harmful substances. Their perforated design allows for quick and effective drainage, which is vital for maintaining a sterile environment.

Technical Benefits of Innovative Floor Drain Covers

Innovative floor drain covers offer several technical benefits:

- Corrosion Resistance: Stainless steel 304 is highly resistant to corrosion, making it ideal for use in electronics manufacturing, where exposure to various chemicals is common.

- Durability: These covers are designed to withstand heavy loads and high traffic, ensuring long-term performance without frequent replacements.

- Hygiene: The smooth surface of stainless steel is easy to clean and sanitize, which is essential for maintaining a contamination-free environment.

- Customizable Perforation Patterns: Different perforation patterns can be customized to suit specific drainage requirements, enhancing efficiency and functionality.

Design Considerations for Innovative Floor Drain Covers in Electronics Manufacturing

Designing floor drain covers for electronics manufacturing requires careful consideration of various factors to ensure optimal performance:

- Material Selection: Stainless steel 304 is preferred for its strength, corrosion resistance, and ease of cleaning.

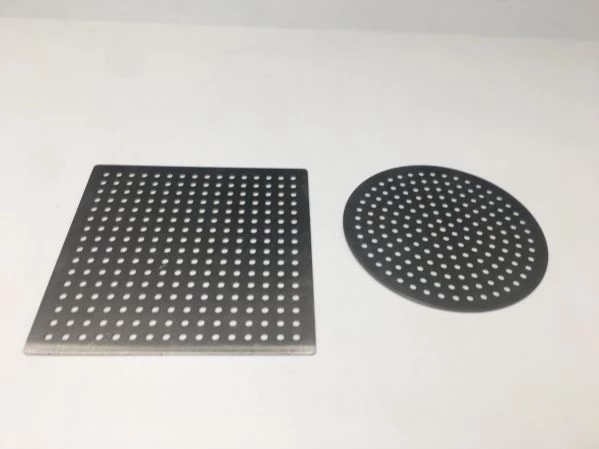

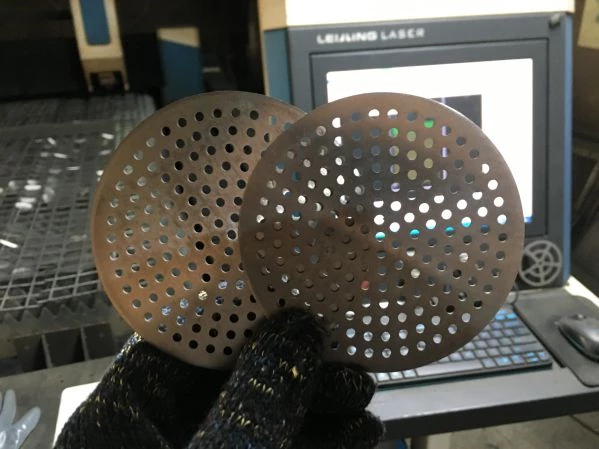

- Perforation Pattern: The pattern of the perforations should be selected based on the specific drainage needs of the facility. Common patterns include round holes, square holes, and slotted holes.

- Thickness and Size: The thickness (1mm to 2mm) and size (30mm to 180mm diameter) should be chosen based on the expected load and area of installation.

- Finish: Different finishes (brushed, polished, matte) can be selected to match the aesthetic and functional requirements of the facility.

Ensuring Cleanroom Compatibility with Floor Drain Covers

In electronics manufacturing, maintaining cleanroom standards is paramount. Floor drain covers must be designed to meet these stringent requirements.

- Seamless Integration: Ensure the floor drain covers seamlessly integrate with the flooring to prevent any gaps that could harbor contaminants.

- Electro-Polishing: This process can be used to enhance the surface finish, making it smoother and reducing the risk of particle buildup.

- Antimicrobial Coatings: Applying antimicrobial coatings can further ensure that the drain covers do not become a source of contamination.

Innovative Drain Cover Features for Electronics Manufacturing

Incorporating advanced features into floor drain covers can significantly enhance their functionality:

- Anti-Slip Surfaces: Ensuring safety in wet areas by preventing slips and falls.

- Quick-Release Mechanisms: For easy removal and cleaning, facilitating regular maintenance without disrupting operations.

- Integrated Filtration: Built-in filtration systems to capture fine particles, preventing them from entering the drainage system.

Environmental Impact and Sustainability

Sustainability is a growing concern in electronics manufacturing. Using stainless steel 304 for floor drain covers contributes to environmental sustainability:

- Recyclability: Stainless steel is 100% recyclable, reducing waste and supporting sustainable practices.

- Long Lifespan: The durability of stainless steel reduces the need for frequent replacements, conserving resources.

- Eco-Friendly Production: Modern manufacturing processes for stainless steel are designed to minimize environmental impact, using energy-efficient techniques and reducing emissions.

Customize Your Innovative Floor Drain Covers from Our Factory

Overview of the Customization Process

Our customization process is designed to provide tailored solutions that meet the specific requirements of electronics manufacturing facilities. Here’s how it works:

- Consultation: We begin with a thorough consultation to understand your needs and preferences.

- Design: Our design team creates detailed plans based on your specifications.

- Production: Using advanced manufacturing techniques, we produce the customized floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

Benefits of Custom Solutions Tailored to Specific Electronics Manufacturing Requirements

Customizing floor drain covers for electronics manufacturing offers several benefits:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance the durability and performance of the covers.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team is ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.