Research laboratories demand the highest standards of cleanliness, safety, and efficiency. An often overlooked yet critical component in maintaining these standards is the floor drain cover. High-quality stainless steel 304 perforated floor drain covers ensure optimal drainage, hygiene, and durability in these environments. This article explores the importance of floor drain covers in research labs, the benefits of stainless steel 304, installation techniques, maintenance practices, and the value of customized solutions tailored to specific laboratory needs.

Importance of Floor Drain Covers in Research Laboratories

Floor drain covers manage wastewater effectively, prevent clogging, and maintain hygienic conditions. Laboratories frequently deal with various chemicals, biological materials, and water spills, making efficient drainage systems crucial. Stainless steel 304 perforated floor drain covers ensure that liquids are safely and effectively removed, reducing the risk of contamination and accidents. These covers also prevent solid waste from entering the drainage system, thus maintaining a clean and safe environment essential for sensitive research activities.

Benefits of Perforated Floor Drain Covers

Stainless steel 304 perforated floor drain covers offer numerous advantages that make them ideal for research laboratories:

- Corrosion Resistance: Stainless steel 304 is highly resistant to corrosion, essential in environments exposed to chemicals and water.

- Durability: These covers can withstand heavy traffic and equipment loads, ensuring long-term performance.

- Hygiene: Stainless steel is easy to clean and does not harbor bacteria, maintaining high sanitation standards.

- Aesthetic Appeal: The sleek, modern look of stainless steel enhances the professional appearance of laboratories.

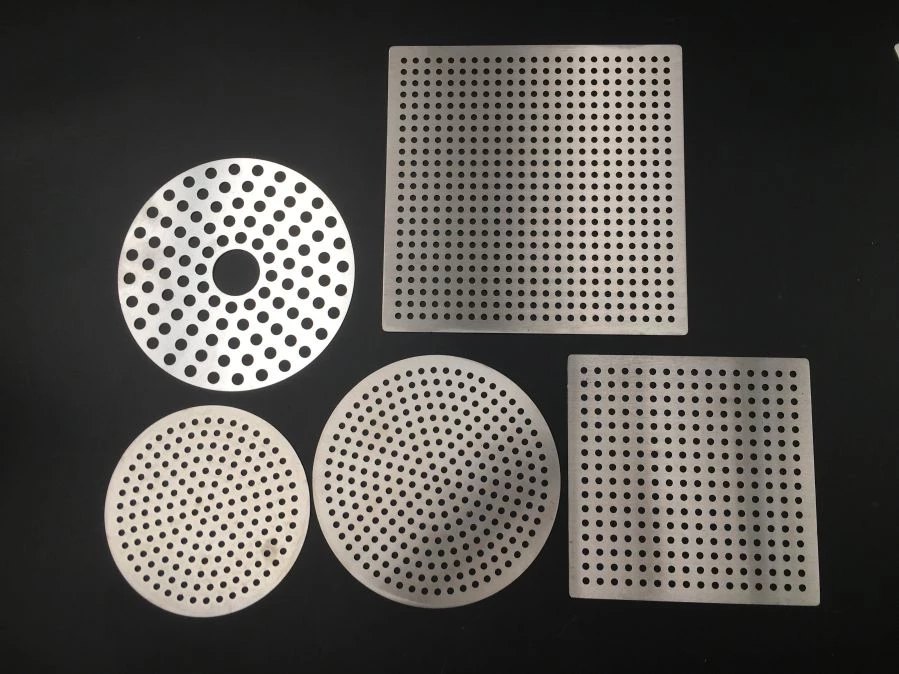

- Customizable Designs: The perforated patterns can be tailored to meet specific drainage needs, ensuring optimal functionality.

Installation Techniques

Proper installation of floor drain covers ensures their efficiency and longevity. Follow these key steps for effective installation:

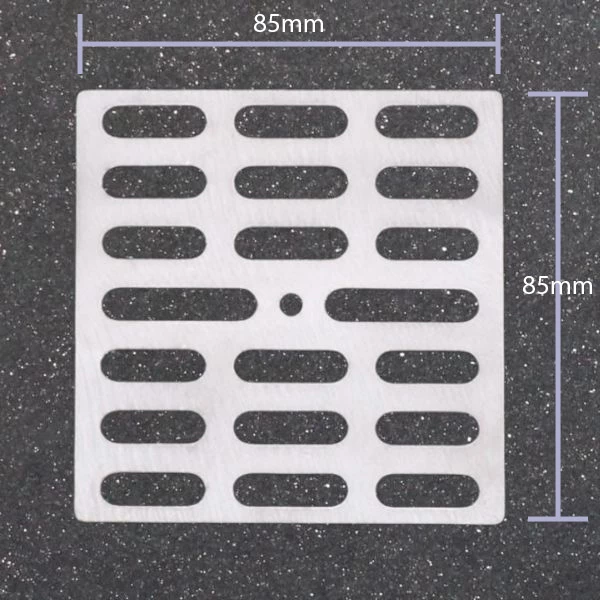

- Site Assessment: Evaluate the drainage requirements and select the appropriate cover size and perforation pattern.

- Preparation: Clean the installation area thoroughly to ensure a secure fit. Remove any debris or old covers.

- Measurement: Accurately measure the drain opening to choose the correct size cover. Ensure a snug fit without gaps.

- Installation: Place the cover over the drain, aligning it correctly. Secure it using screws or locking mechanisms if applicable.

- Testing: Pour water to test drainage efficiency and check for any leaks or misalignment.

Maintenance of Perforated Floor Drain Covers

Regular maintenance is essential to keep floor drain covers functioning optimally. Here are some maintenance tips:

- Cleaning: Regularly clean the covers to remove debris and prevent clogging. Use appropriate cleaning agents for stainless steel.

- Inspection: Periodically inspect the covers for any signs of damage or wear. Replace covers showing significant wear or corrosion.

- Lubrication: Apply lubricants to moving parts and screws to prevent rust and ensure easy removal for cleaning.

- Record Keeping: Maintain logs of inspections and maintenance activities to track the condition of the drain covers and schedule timely replacements.

Customizing Stainless Steel 304 Perforated Floor Drain Covers

Custom floor drain covers offer tailored solutions that meet specific needs in research laboratories. Benefits of custom covers include:

- Perfect Fit: Custom covers are designed to fit precisely, eliminating gaps and ensuring efficient drainage.

- Enhanced Durability: Materials and designs can be selected based on the specific environment, enhancing the longevity and performance of the covers.

- Aesthetic Appeal: Custom designs can match the facility’s aesthetic requirements, contributing to a professional appearance.

- Functional Features: Additional features, such as anti-slip surfaces or locking mechanisms, can be incorporated to enhance safety and functionality.

How to Choose the Right Floor Drain Cover Dealer

Selecting the right dealer for stainless steel 304 perforated floor drain covers is crucial for ensuring quality and reliability. Consider the following factors when choosing a dealer:

- Reputation: Look for dealers with a proven track record and positive customer reviews. A reputable dealer is more likely to provide high-quality products and reliable service.

- Product Range: Ensure the dealer offers a wide range of floor drain covers in different designs to meet your specific needs.

- Customization Options: Choose a dealer that provides custom solutions, allowing you to tailor the drain covers to your facility’s requirements.

- Technical Support: A dealer with strong technical support can assist with installation, maintenance, and troubleshooting, ensuring the longevity and effectiveness of the drain covers.

- Pricing and Terms: Compare pricing and terms from multiple dealers to ensure you get the best value for your investment. Consider factors such as bulk order discounts, delivery times, and warranty options.

Innovative Designs

Innovative designs in floor drain covers can significantly enhance their functionality and efficiency in research laboratories. Advanced features such as anti-slip surfaces, integrated locking mechanisms, and customizable perforation patterns ensure that the covers meet specific drainage needs while maintaining safety and hygiene standards. Additionally, innovative designs can improve the ease of cleaning and maintenance, further enhancing their practicality in busy laboratory environments.

Sustainable Solutions

Sustainability is becoming increasingly important in all industries, including research laboratories. Stainless steel 304 perforated floor drain covers offer a sustainable solution due to their long lifespan, recyclability, and low maintenance requirements. By choosing high-quality, durable materials, laboratories can reduce waste and contribute to environmental conservation efforts. Additionally, the efficiency and effectiveness of these covers can help laboratories comply with environmental regulations and standards.

In conclusion, stainless steel 304 perforated floor drain covers are essential components in research laboratories, ensuring efficient drainage, safety, and hygiene. By understanding the benefits, installation techniques, and maintenance practices, you can make informed decisions that enhance the performance and longevity of your drainage systems. Custom solutions offer additional benefits, providing tailored features that meet the specific needs of your facility. Choosing the right dealer further ensures the quality and reliability of your floor drain covers, contributing to the overall efficiency and safety of your laboratory.

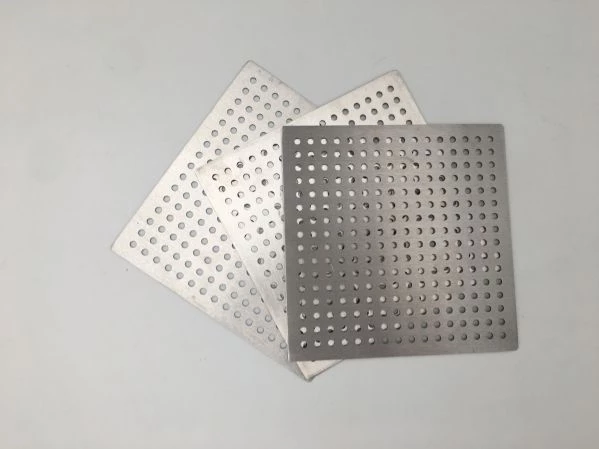

Customize Your Floor Drain Covers from Our Factory

Our factory specializes in producing high-quality, custom stainless steel 304 perforated floor drain covers tailored to the unique needs of research laboratories. We offer a comprehensive range of designs, ensuring each cover meets the specific requirements of your facility. Our team of experts works closely with clients to understand their needs and provide solutions that enhance safety, efficiency, and aesthetics. Contact us today to learn more about our customization options and how we can help you achieve optimal drainage solutions for your laboratory.