Maintaining a sterile environment is crucial in clean rooms across various industries, such as pharmaceuticals, biotechnology, and semiconductor manufacturing. One critical component in ensuring these environments remain uncontaminated is the floor drain cover. High-performance floor drain covers are specifically designed to meet the stringent requirements of clean rooms, providing efficient drainage while maintaining sterility and ease of maintenance. This article explores the importance, benefits, and various aspects of high-performance floor drain covers for clean rooms.

High-Performance Floor Drain Covers

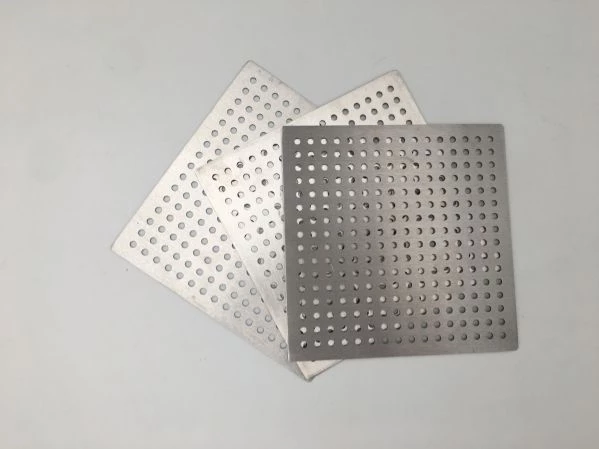

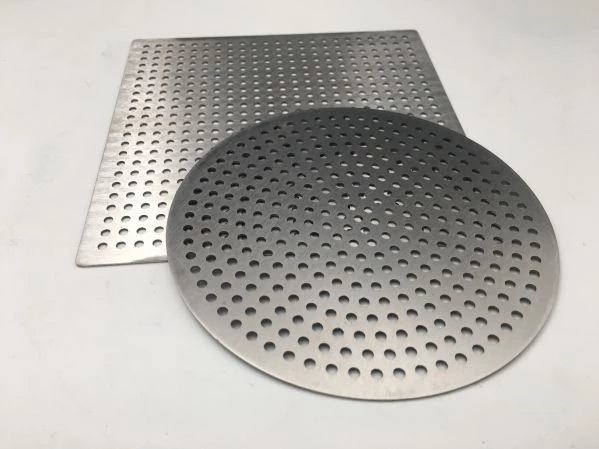

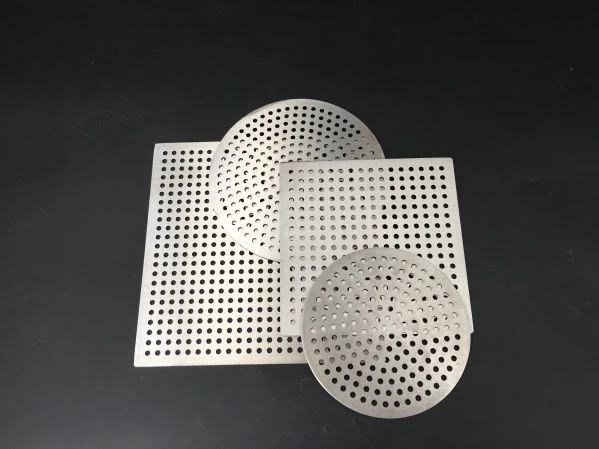

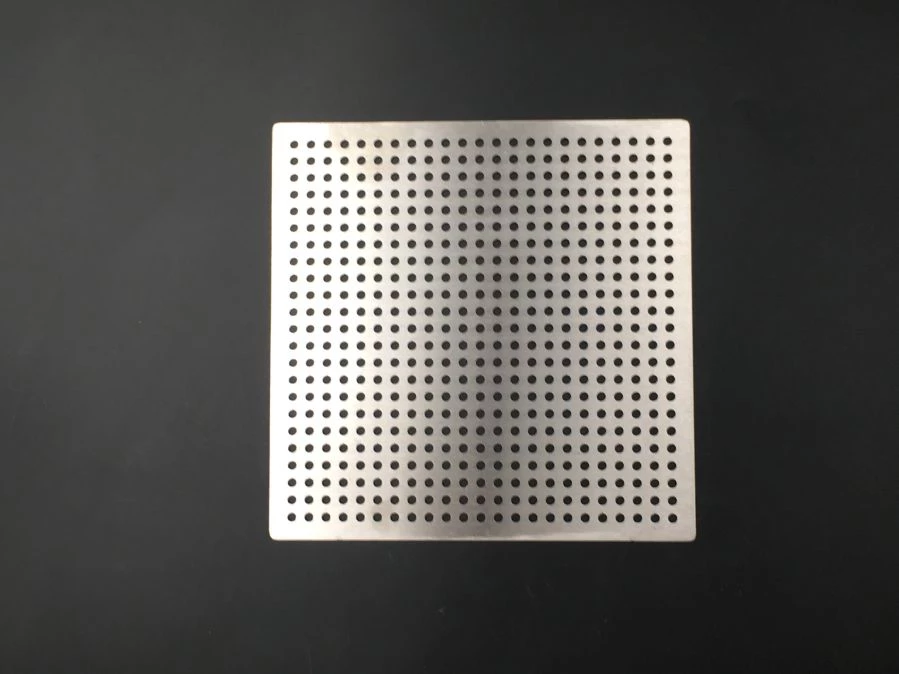

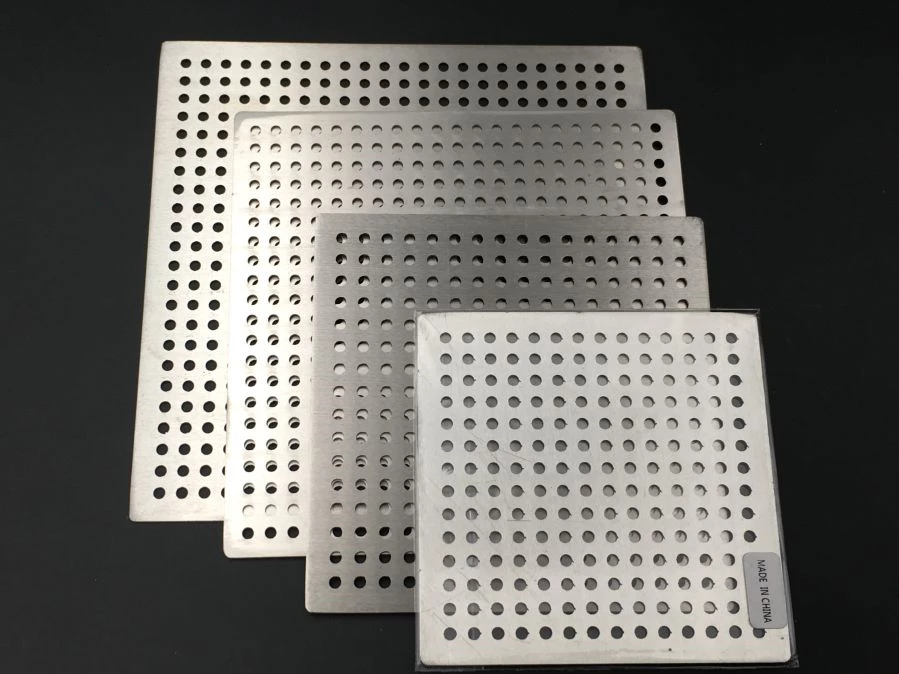

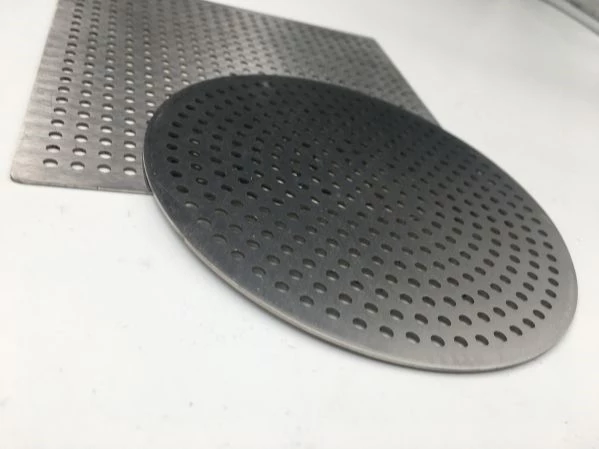

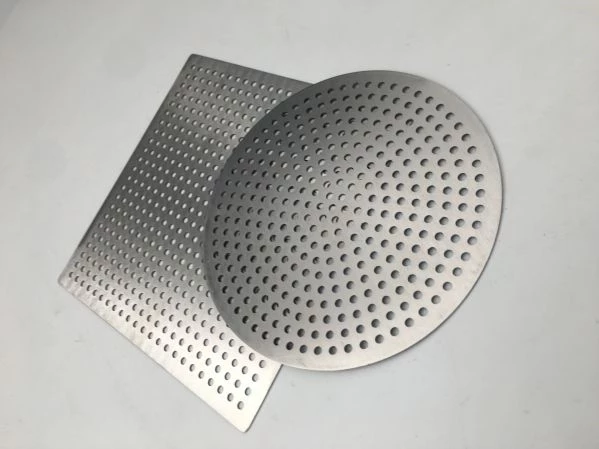

High-performance floor drain covers are engineered to provide optimal drainage solutions in environments that demand high levels of cleanliness and contamination control. These covers are typically made from durable materials like stainless steel, which resists corrosion and is easy to sanitize. The design of these covers often includes fine perforations or grates that effectively filter out debris while allowing water and other liquids to drain efficiently. In clean rooms, where even the smallest particles can compromise the integrity of the environment, having the right floor drain cover is essential.

Benefits of Using Floor Drain Covers in Clean Rooms

Using high-performance floor drain covers in clean rooms offers several benefits:

- Contamination Control: These covers prevent contaminants from entering the drainage system, thus maintaining the sterile conditions required in clean rooms.

- Durability and Longevity: Made from high-quality materials like stainless steel, these covers are resistant to corrosion, wear, and damage, ensuring long-term performance.

- Ease of Cleaning: The smooth surfaces and precise designs of these covers make them easy to clean and sanitize, which is crucial in environments where hygiene is paramount.

- Efficient Drainage: Designed to handle various types of liquids, these covers ensure efficient drainage, preventing water buildup and potential contamination.

- Compliance: High-performance floor drain covers meet the stringent standards and regulations required for clean room environments, ensuring compliance with industry requirements.

Types of Floor Drain Covers for Clean Rooms

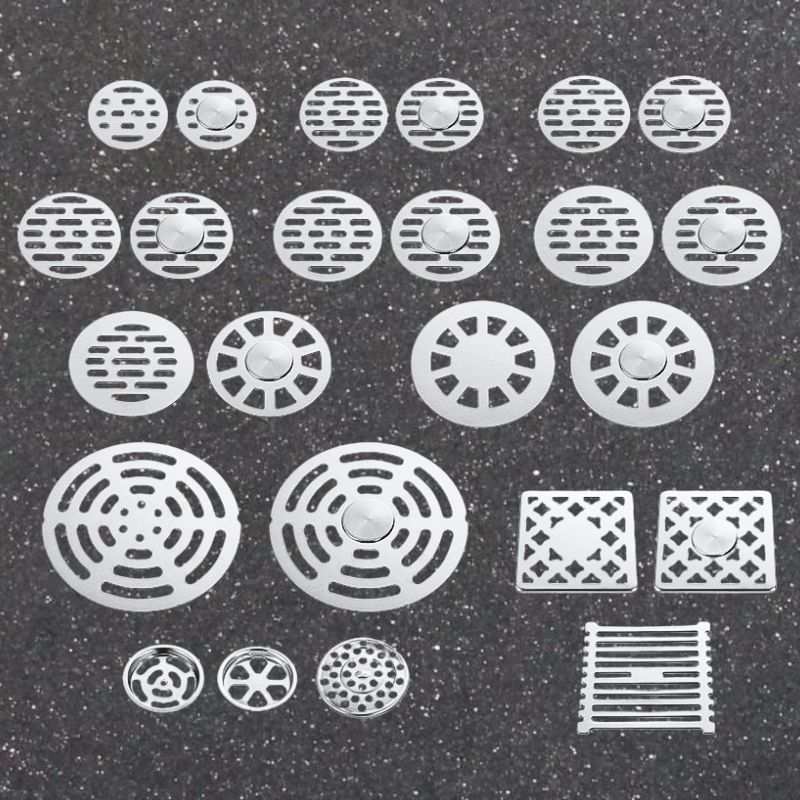

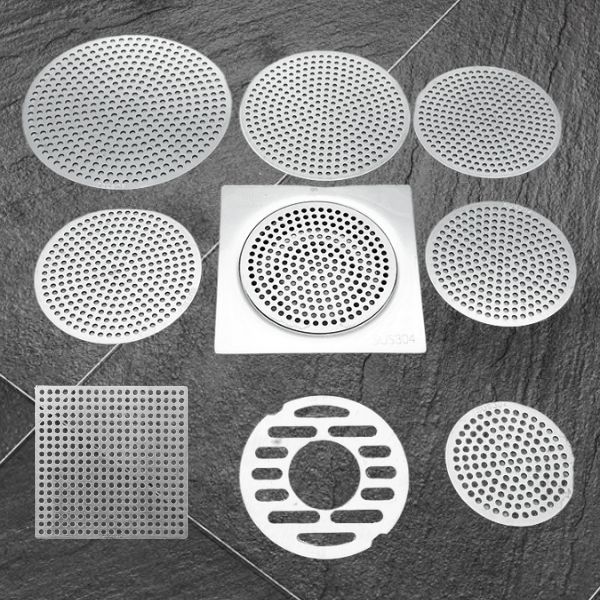

There are several types of floor drain covers suitable for clean rooms, each designed to meet specific needs:

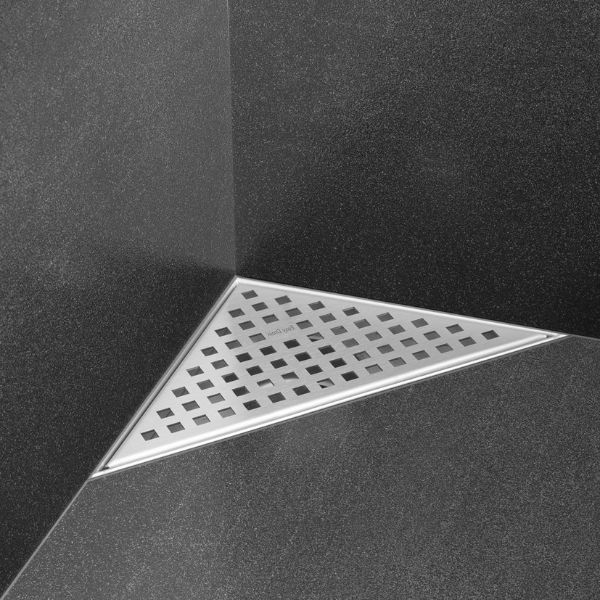

- Grated Covers: Featuring a grid-like pattern, these covers allow for efficient drainage while trapping larger debris.

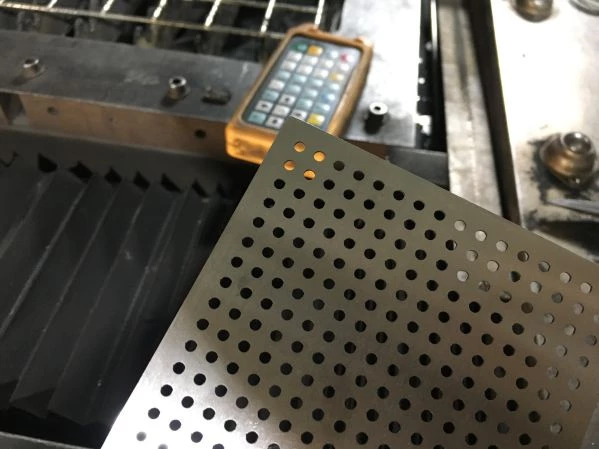

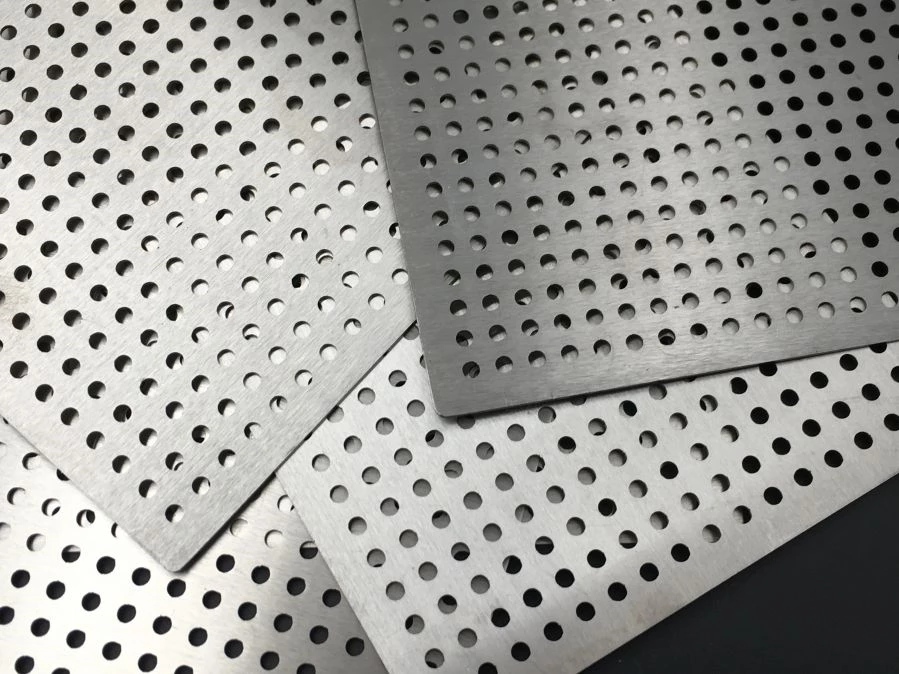

- Perforated Covers: These covers have small holes that filter out finer particles and are ideal for environments that require higher levels of cleanliness.

- Solid Covers with Seals: These covers provide a tight seal to prevent any liquid or contaminants from entering the drain when not in use.

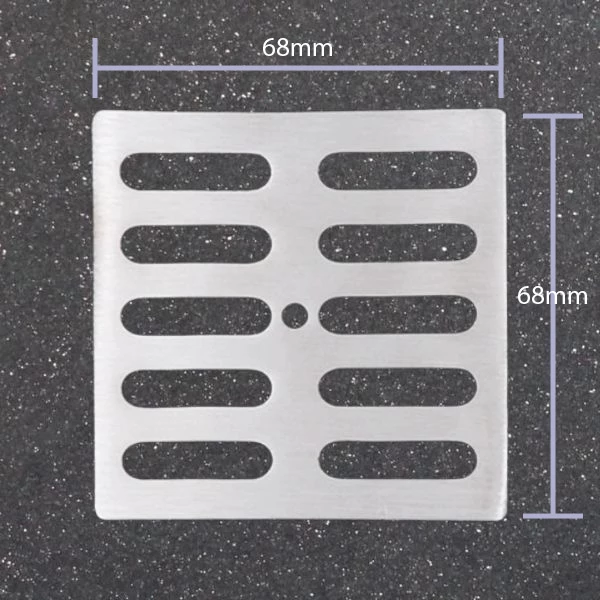

- Slotted Covers: Designed with narrow slots, these covers combine efficient drainage with debris trapping capabilities.

Each type of cover can be customized to fit the specific requirements of the clean room environment, ensuring optimal performance.

Selecting the Right Floor Drain Cover for Your Clean Room

Choosing the appropriate floor drain cover for a clean room involves considering several factors:

- Material: Stainless steel is the most common material used due to its durability, corrosion resistance, and ease of cleaning.

- Design: The design should facilitate efficient drainage while preventing contamination. Consider the size and pattern of perforations or slots based on the specific needs of your clean room.

- Compliance: Ensure the drain cover meets industry standards and regulations for clean rooms.

- Customization: Depending on your clean room’s unique requirements, custom drain covers might be necessary to provide the best fit and functionality.

- Maintenance: Consider how easy the drain cover is to remove, clean, and reassemble, as regular maintenance is essential in clean rooms.

Installation and Maintenance

Proper installation and maintenance are crucial for the effectiveness of floor drain covers in clean rooms:

- Installation:

- Ensure the drain cover fits snugly and securely to prevent any gaps where contaminants could enter.

- Follow manufacturer guidelines for installation to ensure compliance and optimal performance.

- Consider professional installation to guarantee that all aspects are correctly handled.

- Maintenance:

- Regularly inspect the drain covers for any signs of damage or wear.

- Clean and sanitize the covers frequently to maintain hygiene and prevent contamination.

- Replace any damaged or worn-out covers promptly to ensure continuous protection.

Maintaining a strict schedule for cleaning and inspection can significantly extend the lifespan of floor drain covers and ensure they continue to function effectively.

Customize Your Floor Drain Covers for Clean Rooms

Customization of floor drain covers can offer significant advantages in clean room environments:

- Tailored Fit: Custom covers can be designed to fit specific drain sizes and shapes, ensuring a secure and effective fit.

- Specific Requirements: Customization allows for the inclusion of specific features such as unique perforation patterns, additional sealing mechanisms, or reinforced materials.

- Branding and Identification: Custom drain covers can include branding or identification marks, which can be useful for large facilities with multiple clean rooms.

- Enhanced Functionality: Depending on the clean room’s needs, custom covers can be designed to handle specific types of liquids or debris more effectively.

Working with a manufacturer that offers a custom service like FILTERMFRS™ ensures that your floor drain cover meets all of your specific requirements and provides optimal performance in maintaining cleanroom standards.