Railway stations are dynamic environments requiring robust infrastructure to ensure smooth operations and passenger safety. One critical component of this infrastructure is the floor drain cover. These covers manage water drainage, maintain hygiene, and prevent accidents. As a leading floor drain covers vendor, we provide high-quality, customizable solutions designed to meet the rigorous demands of railways and stations. This article explores the application, technical benefits, specifications, design considerations, manufacturing process, longevity, environmental impact, and customization of floor drain covers specifically tailored for railways and stations.

Application of Perforated Floor Drain Covers in Railways and Stations

Floor drain covers in railways and stations serve multiple purposes. They ensure effective water drainage, preventing water accumulation that can cause slip hazards. These covers are vital in high-traffic areas like platforms, waiting areas, and maintenance facilities. Stainless steel 304 perforated covers are particularly suitable due to their corrosion resistance, durability, and aesthetic appeal. They handle the high volume of passengers and harsh environmental conditions, ensuring safety and hygiene.

Technical Benefits of Floor Drain Covers

Stainless steel 304 perforated floor drain covers offer numerous technical benefits, making them ideal for railway and station applications. As a premier floor drain covers vendor, we emphasize the technical advantages of our products:

- Corrosion Resistance: Stainless steel 304 withstands exposure to moisture and chemicals, ensuring long-term performance.

- Durability: These covers can handle heavy foot traffic and impacts, making them suitable for busy stations.

- Hygiene: Stainless steel is easy to clean and maintain, critical for public transportation hubs.

- Load Bearing Capacity: They are designed to bear significant loads, ensuring they remain intact under heavy use.

- Aesthetic Appeal: The polished or brushed finishes add a professional look to any facility.

Technical Specifications of Floor Drain Covers

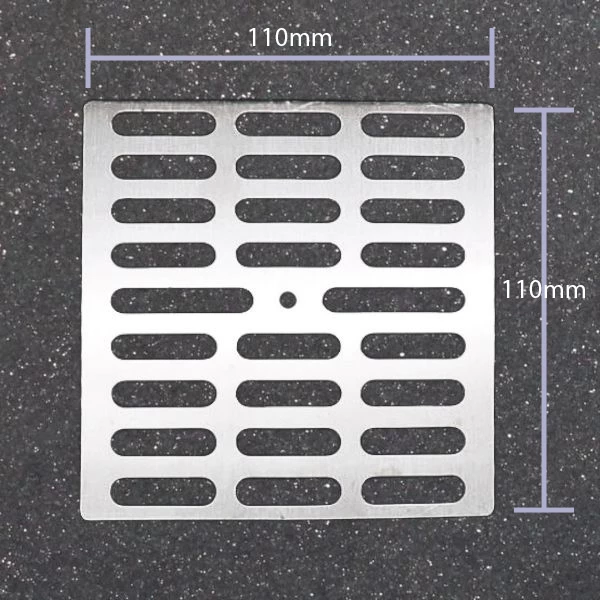

Our stainless steel 304 perforated floor drain covers come with the following specifications:

- Thickness: 1mm to 2mm, customizable to meet specific requirements.

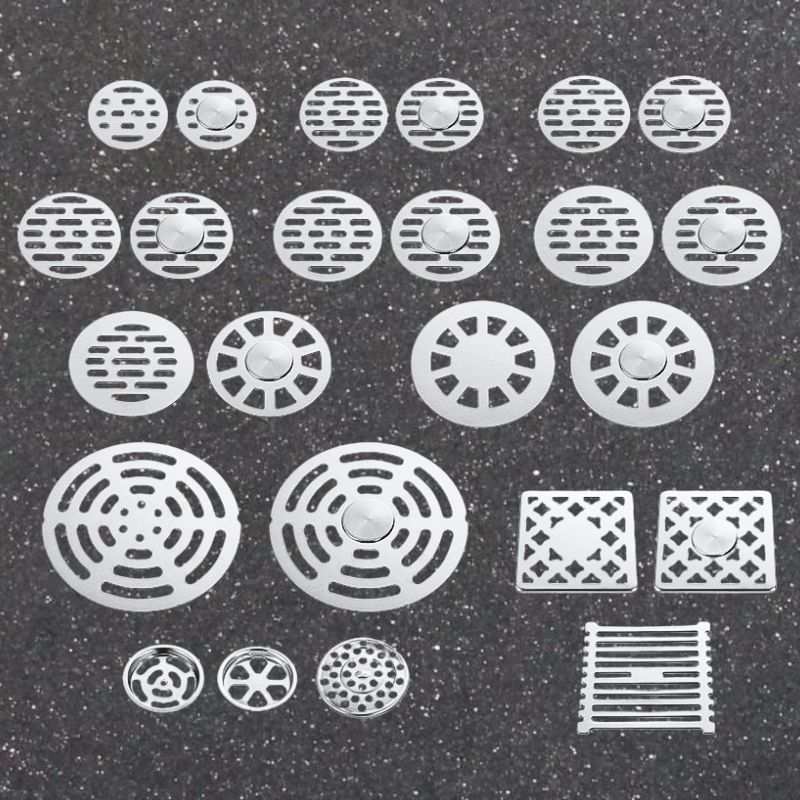

- Shape: Available in round and square, with custom shapes available.

- Diameter: 30mm to 180mm, customizable for non-standard sizes.

- Finish: Brushed, Polished, Matte, catering to different aesthetic and functional needs.

- Perforation Patterns: Round Holes, Square Holes, Slotted Holes, and custom patterns. For more about perforation patterns, read our detailed article: Optimizing Perforation Patterns for Efficient Drain Covers.

Design Considerations for Floor Drain Covers in Railways and Stations

When designing floor drain covers for railways and stations, several factors must be considered:

- Load Capacity: Ensure the covers can handle the weight of thousands of passengers daily.

- Slip Resistance: Incorporate anti-slip features to prevent accidents, especially in wet conditions.

- Ease of Cleaning: Design covers that are easy to remove and clean to maintain hygiene.

- Custom Fit: Ensure the covers fit perfectly within the existing infrastructure to avoid gaps and ensure seamless integration.

- Aesthetic Integration: Choose finishes and designs that complement the station’s architecture and branding.

Manufacturing Process of Floor Drain Covers in Our Factory

Our manufacturing process for stainless steel 304 perforated floor drain covers involves several precise steps:

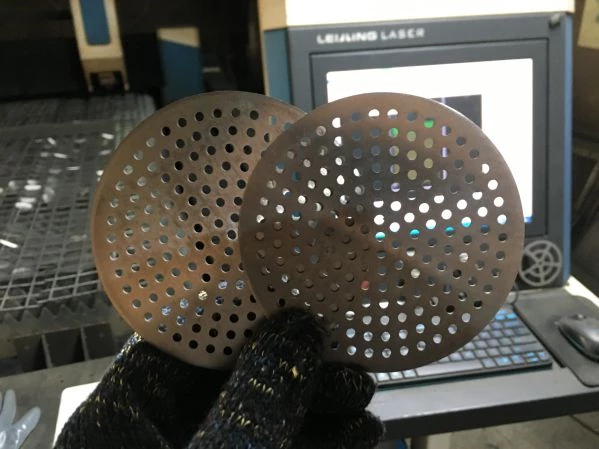

- Material Selection: We source high-quality stainless steel 304 to ensure durability and performance.

- Cutting: Using advanced CNC machines, we cut the steel sheets to the required dimensions.

- Perforation: We use precision perforation techniques to create the desired patterns, ensuring efficient drainage and aesthetic appeal.

- Finishing: The covers undergo finishing processes such as brushing, polishing, or matte treatment to meet aesthetic and functional requirements.

- Quality Control: Each cover undergoes rigorous quality checks to ensure they meet our high standards of durability, fit, and finish.

- Customization: We offer customization options to tailor the covers to specific client needs, ensuring perfect fit and performance.

Longevity of Floor Drain Covers and Our After-Sales Service

Our stainless steel 304 perforated floor drain covers are built to last, thanks to their robust construction and high-quality materials. We ensure longevity through:

- High-Quality Materials: Using stainless steel 304 ensures resistance to corrosion and wear.

- Precision Manufacturing: Advanced manufacturing techniques guarantee durability and performance.

- Regular Maintenance: Proper installation and regular maintenance enhance the lifespan of the covers.

We also offer comprehensive after-sales service, including:

- Installation Support: Guidance on proper installation techniques.

- Maintenance Tips: Advice on cleaning and maintaining the covers.

- Replacement Services: Prompt replacement of covers that show signs of wear or damage.

- Customer Support: Dedicated support team to address any issues or concerns.

Environmental Impact and Sustainability

Our commitment to sustainability is evident in our manufacturing processes and product design. Stainless steel 304 is an eco-friendly material, fully recyclable and long-lasting, reducing the need for frequent replacements. Our production methods minimize waste, and we continually strive to improve our environmental footprint through:

- Efficient Use of Materials: Maximizing the use of raw materials to reduce waste.

- Recycling: Utilizing recycled materials wherever possible.

- Energy Efficiency: Implementing energy-efficient processes in our manufacturing facilities.

Customize Your Floor Drain Covers from Our Factory

Overview of the Customization Process Offered by Our Factory

We offer a seamless customization process to ensure your floor drain covers meet your specific requirements:

- Consultation: Discuss your needs with our experts to determine the best specifications for your project.

- Design: Our design team creates detailed plans based on your requirements, including size, shape, finish, and perforation patterns.

- Prototype: We produce a prototype for your approval, ensuring it meets all specifications and performance criteria.

- Production: Upon approval, we commence full-scale production, adhering to strict quality control measures.

- Delivery: We ensure timely delivery of your custom floor drain covers, ready for installation.

Benefits of Custom Solutions Tailored to Specific Floor Drain Covers Requirements

Custom solutions offer several benefits:

- Perfect Fit: Ensures seamless integration with existing infrastructure.

- Enhanced Performance: Tailored designs meet specific functional requirements.

- Aesthetic Appeal: Custom finishes and patterns align with the facility’s branding and design.

- Increased Durability: Custom materials and construction methods enhance longevity.

Contact Us

For enterprise customers interested in custom floor drain covers, contact us today to discuss your requirements. Our team of experts is ready to provide tailored solutions that enhance the efficiency, safety, and aesthetic appeal of your logistics hubs.