Floor drain covers are essential components in the food and beverage distribution industry. They ensure efficient drainage, maintain hygiene, and contribute to the overall safety of the facilities. This article will explore the technical benefits, design considerations, manufacturing process, after-sales service, and how to find the right vendor for floor drain covers, with a focus on the offerings from FILTERMFRS™.

Technical Benefits of Floor Drain Covers

Floor drain covers in the food and beverage industry provide several technical benefits:

- Corrosion Resistance: Stainless steel 304 is highly resistant to corrosion, making it ideal for environments exposed to moisture and chemicals.

- Durability: These covers withstand heavy loads and impacts, ensuring long-term performance in high-traffic areas.

- Hygiene: Stainless steel is easy to clean and maintain, crucial for meeting stringent hygiene standards in food and beverage facilities.

- Safety: Properly designed drain covers reduce slip hazards by preventing water accumulation and ensuring efficient drainage.

- Versatility: Available in various shapes, sizes, and perforation patterns to meet specific operational needs.

Design Considerations for Floor Drain Covers in Food & Beverage Distribution

When designing floor drain covers for the food and beverage distribution industry, consider the following:

- Material Selection: Stainless steel 304 is preferred due to its corrosion resistance, durability, and ease of cleaning.

- Thickness: The covers should be thick enough to withstand heavy loads, typically ranging from 1mm to 2mm.

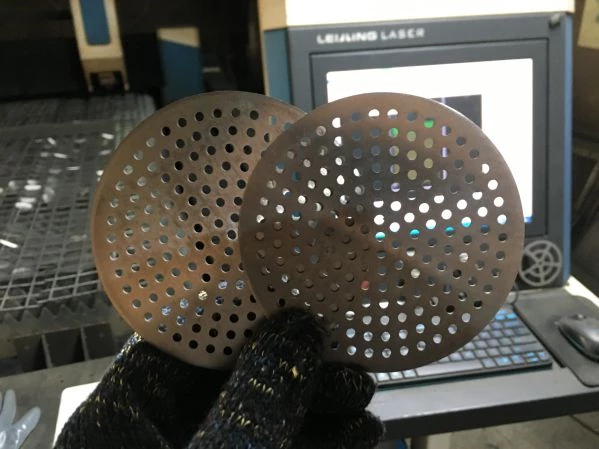

- Shape and Size: Custom shapes and sizes ensure a perfect fit for different drainage systems. Common shapes include round and square, with diameters ranging from 30mm to 180mm.

- Finish: Choose finishes like brushed, polished, or matte to match the facility’s aesthetic and functional requirements.

- Perforation Patterns: Select appropriate perforation patterns (round holes, square holes, slotted holes) to balance drainage efficiency and debris filtration. For more details on optimizing perforation patterns, read Optimizing Perforation Patterns for Efficient Drain Covers.

Custom Solutions for Food & Beverage Facilities

Providing custom solutions for floor drain covers ensures they meet the specific needs of food and beverage facilities:

- Tailored Designs: Custom designs address unique operational challenges, ensuring efficient drainage and hygiene.

- Enhanced Durability: Custom materials and finishes enhance durability and resistance to environmental factors.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of the facility, contributing to a professional appearance.

- Operational Efficiency: Custom solutions improve overall operational efficiency by addressing specific facility needs.

Quality Control in Floor Drain Cover Production

Quality control is crucial in manufacturing floor drain covers to ensure they meet industry standards:

- Material Inspection: Inspecting raw materials (stainless steel 304) to ensure they meet quality standards.

- Dimensional Accuracy: Using precision tools to check the dimensions and ensure the covers fit perfectly.

- Surface Finish: Ensuring the surface finish (brushed, polished, matte) meets the required aesthetic and functional standards.

- Perforation Consistency: Checking the perforation patterns for consistency to ensure efficient drainage and debris filtration.

- Load Testing: Conducting load tests to ensure the covers can withstand heavy loads and impacts without deformation.

After-Sales Service

Reliable after-sales service is crucial for maintaining long-term relationships with clients. Our after-sales service includes:

- Technical Support: Our team of experts provides ongoing technical support to ensure optimal product performance.

- Maintenance Guidance: Offering detailed maintenance guides to help clients keep their floor drain covers in top condition.

- Replacement Parts: Providing quick access to replacement parts to minimize downtime and maintain operational efficiency.

- Customer Feedback: Actively seeking and incorporating customer feedback to continually improve our products and services.

Choose FILTERMFRS™ as Your Vendor of Floor Drain Covers

FILTERMFRS™ specializes in producing high-quality, custom stainless steel 304 perforated floor drain covers tailored to the unique needs of food and beverage distribution facilities. Our offerings include:

- Comprehensive Range: We offer a wide range of designs, ensuring each cover meets the specific requirements of your facility.

- Customization: Our team works closely with clients to understand their needs and provide tailored solutions that enhance safety, efficiency, and aesthetics.

- Advanced Manufacturing: Using state-of-the-art technology, we ensure precision and consistency in every product.

- Quality Assurance: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Efficient Logistics: We handle all aspects of logistics to ensure timely delivery to your location.

- Dedicated Support: Our after-sales service includes technical support, maintenance guidance, and quick access to replacement parts.

Contact us today to learn more about our customization options and how we can help you achieve optimal drainage solutions for your food and beverage distribution facility.