Food packaging plants demand stringent hygiene standards and robust infrastructure. One crucial component is the floor drain cover, which ensures proper drainage, maintains cleanliness, and prevents contamination. This article focuses on the design and technical aspects of stainless steel 304 perforated floor drain covers, tailored specifically for food packaging plants. We will explore the technical specifications, design considerations, manufacturing processes, and the benefits of customized solutions.

Importance of Floor Drain Covers in Food Packaging Plants

In food packaging plants, maintaining a hygienic environment is paramount. Floor drain covers play a critical role in this process by preventing debris from clogging the drainage system and ensuring efficient water flow. These covers help avoid water accumulation, which can lead to slip hazards, equipment damage, and potential contamination. High-quality stainless steel 304 perforated floor drain covers are ideal for such environments due to their durability, corrosion resistance, and ease of cleaning, ensuring a safe and productive workspace.

Benefits of Stainless Steel 304 Perforated Floor Drain Covers

Stainless steel 304 perforated floor drain covers offer numerous advantages, making them the preferred choice for food packaging plants:

- Corrosion Resistance: Stainless steel 304 is highly resistant to corrosion, making it suitable for environments with frequent exposure to water and cleaning agents.

- Durability: These covers are robust and can withstand heavy loads and impacts, ensuring long-term performance in high-traffic areas.

- Hygiene: Stainless steel is non-porous and easy to clean, helping maintain the high hygiene standards required in food packaging plants.

- Aesthetic Appeal: The sleek appearance of stainless steel adds a professional look to any facility.

- Versatility: The perforated design can be customized to meet specific drainage requirements, ensuring optimal performance.

Technical Specifications of Floor Drain Covers

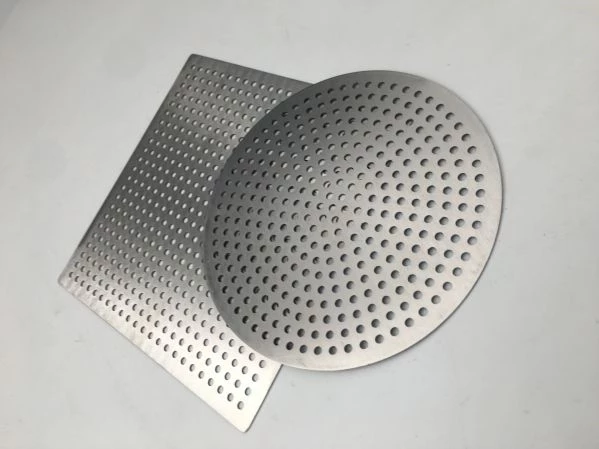

Our stainless steel 304 perforated floor drain covers are designed with the following technical specifications to meet the rigorous demands of food packaging plants:

- Thickness: 1mm to 2mm, customizable according to specific requirements.

- Shape: Available in round and square shapes, with the option for custom shapes.

- Diameter: Standard sizes range from 30mm to 180mm, with the possibility to customize for non-standard sizes.

- Finish: Options include brushed, polished, and matte finishes, catering to different aesthetic and functional needs.

- Perforation Patterns: Available in round holes, square holes, slotted holes, and custom patterns. For more details on optimizing perforation patterns, please read this article:

Optimizing Perforation Patterns for Efficient Drain Covers.

Design Considerations for Floor Drain Covers in Food Packaging Plants

Designing floor drain covers for food packaging plants involves several critical considerations:

- Load Capacity: The covers must support heavy equipment and foot traffic. Selecting the appropriate thickness and material ensures durability.

- Drainage Efficiency: The perforation pattern and size must allow for efficient water drainage while preventing debris from entering the drainage system.

- Hygiene: The design should facilitate easy cleaning and maintenance, with smooth surfaces that do not harbor bacteria.

- Compatibility: The covers must fit seamlessly into existing drainage systems, requiring precise measurements and customization.

- Safety: Anti-slip features can be incorporated into the design to prevent accidents in wet areas.

Manufacturing Process of Floor Drain Covers in Our Factory

Our manufacturing process for stainless steel 304 perforated floor drain covers involves several key steps to ensure high quality and precision:

- Material Selection: We use high-grade stainless steel 304, known for its corrosion resistance and durability.

- Design and Engineering: Our design team works closely with clients to create custom designs that meet specific requirements. We use advanced CAD software to ensure precision.

- Cutting and Perforation: Using CNC machines, we cut and perforate the stainless steel sheets according to the design specifications. This process ensures accuracy and consistency.

- Finishing: Depending on the client’s preference, the covers undergo brushing, polishing, or matte finishing to achieve the desired look and functionality.

- Quality Control: Each cover undergoes rigorous quality checks to ensure it meets our high standards and the client’s specifications.

- Packaging and Shipping: The finished products are carefully packaged to prevent damage during transit and shipped to the client’s location.

Our After-Sales Service

We pride ourselves on offering exceptional after-sales service to our clients. Our support includes:

- Installation Guidance: We provide detailed instructions and support to ensure proper installation of the floor drain covers.

- Maintenance Tips: Our team offers advice on maintaining the covers to ensure their longevity and performance.

- Warranty: We offer warranties on our products, giving clients peace of mind regarding their investment.

- Customer Support: Our customer service team is available to address any questions or concerns, ensuring a smooth and satisfactory experience.

Floor Drain Cover Manufacturers

As leading manufacturers of stainless steel 304 perforated floor drain covers, we understand the unique requirements of food packaging plants. Our commitment to quality, precision, and customer satisfaction sets us apart in the industry. We continually invest in advanced manufacturing technologies and processes to deliver products that meet the highest standards.

Customize Your Floor Drain Cover from Our Factory

Overview of the Customization Process Offered by Our Factory

Our factory specializes in creating custom floor drain covers tailored to the specific needs of food packaging plants. The customization process includes:

- Consultation: We discuss the client’s requirements, including size, shape, finish, and perforation pattern.

- Design: Our design team creates detailed drawings and prototypes for client approval.

- Manufacturing: Once the design is approved, we proceed with manufacturing using state-of-the-art equipment.

- Quality Assurance: Each cover undergoes thorough testing to ensure it meets the required standards.

- Delivery: The final product is packaged securely and delivered to the client’s location.

The Benefits of Custom Solutions Tailored to Specific Food Packaging Plant Requirements

Custom floor drain covers offer several benefits:

- Perfect Fit: Custom covers are designed to fit precisely, ensuring efficient drainage and easy installation.

- Enhanced Durability: Custom materials and designs can be selected based on the specific environment, enhancing the covers’ longevity.

- Improved Hygiene: Custom designs can incorporate features that facilitate cleaning and maintenance, crucial for maintaining hygiene in food packaging plants.

- Aesthetic Appeal: Custom finishes and designs can match the facility’s aesthetic requirements, contributing to a professional appearance.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team is ready to assist with any inquiries and provide tailored solutions to meet your specific needs.