Perforated metal sheets are indispensable in the food processing realm. Their durability, versatility, and hygienic properties make them an ideal choice for various applications. This article explores the uses and benefits of perforated metal sheets in food processing.

Enhancing Hygiene and Safety

Hygiene and safety are paramount in food processing. Perforated metal sheets contribute significantly to maintaining these standards.

Hygienic Properties

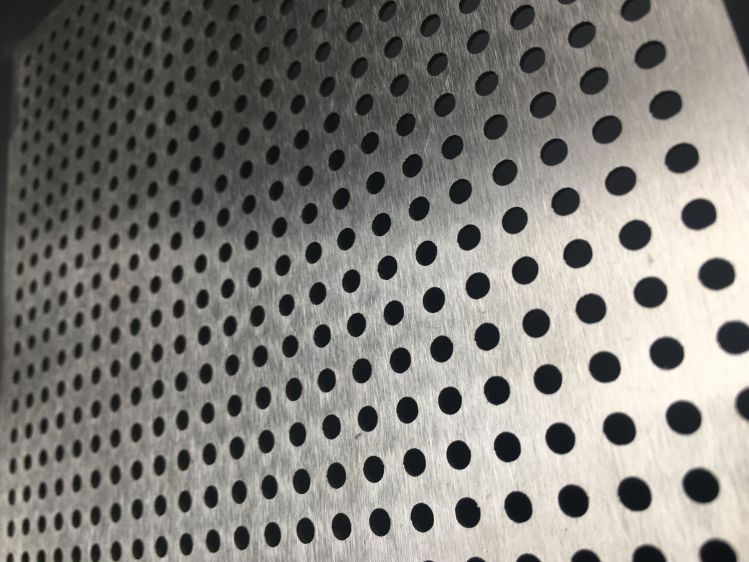

Perforated metal sheets are made from materials such as stainless steel, which is known for its non-porous and corrosion-resistant properties. This makes them easy to clean and sanitize, preventing bacterial growth and ensuring food safety. The smooth surface of stainless steel sheets allows for thorough cleaning, which is essential in environments where food contact is frequent.

Compliance with Safety Standards

Using perforated metal sheets helps food processing facilities comply with stringent safety and hygiene standards. For instance, stainless steel meets the requirements of the Food and Drug Administration (FDA) and the European Union’s regulations for materials in contact with food. Compliance with these standards ensures that food processing equipment and surfaces do not contaminate the products, maintaining high levels of food safety.

Versatile Applications in Food Processing

Perforated metal sheets are used in a variety of applications within the food processing industry, enhancing both functionality and efficiency.

Sifting and Filtering

In food processing, sifting and filtering are essential for removing unwanted particles and ensuring product consistency. Perforated metal sheets with precise hole sizes are used in sifters and filters to separate particles of different sizes. This application is common in the production of flour, sugar, spices, and other powdered ingredients.

Data Point: According to a report by Grand View Research, the global market for food processing equipment is expected to reach USD 80.27 billion by 2025, highlighting the growing demand for efficient sifting and filtering solutions.

Drying and Dehydration

Perforated metal sheets are also used in drying and dehydration processes. Their open structure allows for maximum airflow, which is crucial for efficiently drying food products. This application is particularly important in the production of dried fruits, vegetables, and meat products.

Cooking and Baking

In commercial kitchens and bakeries, perforated metal sheets are used for baking trays, grills, and cooking surfaces. The perforations ensure even heat distribution, leading to consistent cooking and baking results. This is especially beneficial for baking bread, pastries, and cookies.

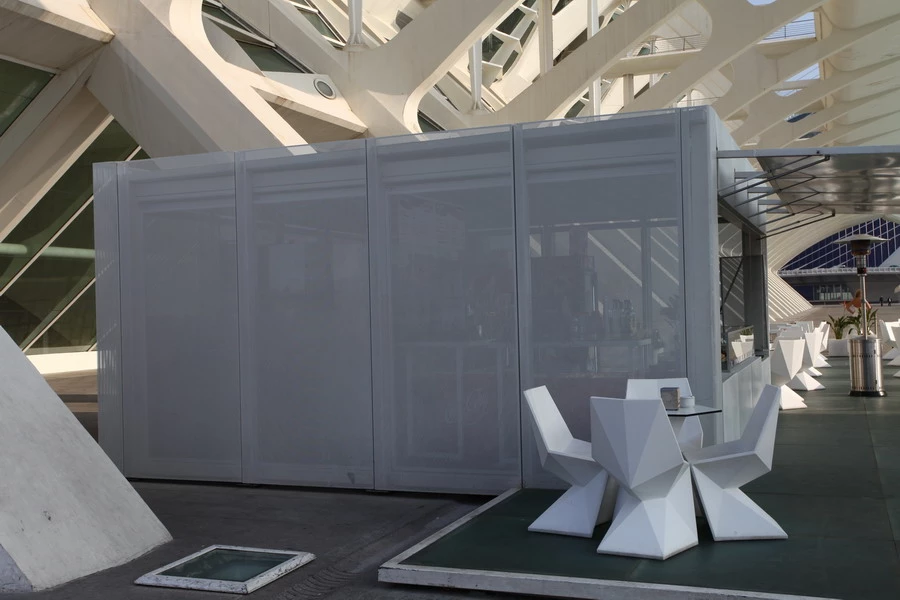

Conveying

Perforated metal sheets are used in conveyor belts within food processing plants. These sheets provide a sturdy and hygienic surface for transporting food products through various stages of processing. The perforations allow for drainage and airflow, which are essential for certain processing steps such as washing and drying.

Benefits of Perforated Metal Sheets in Food Processing

The use of perforated metal sheets in food processing offers several key benefits that enhance operational efficiency and product quality.

Durability and Longevity

Perforated metal sheets, particularly those made from stainless steel, are highly durable and resistant to corrosion. This durability ensures a long lifespan, reducing the need for frequent replacements and minimizing downtime. The longevity of these sheets translates into cost savings for food processing facilities.

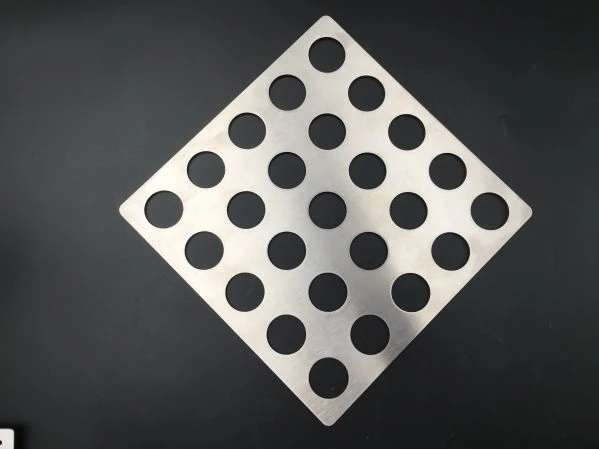

Customization Options

Perforated metal sheets can be customized to meet specific requirements. The size, shape, and pattern of the perforations can be tailored to suit different applications. This customization allows food processing facilities to optimize their equipment for maximum efficiency and product quality.

Improved Product Quality

The precise perforations in metal sheets ensure consistent product quality. For instance, in baking, the even heat distribution provided by perforated trays results in uniformly baked goods. In filtering and sifting, the accuracy of the perforations ensures that only the desired particle sizes are included in the final product.

Efficiency in Processing

Perforated metal sheets enhance the efficiency of various food processing operations. Their open structure allows for better airflow, drainage, and heat transfer, speeding up processes such as drying, cooling, and cooking. This efficiency leads to increased production rates and reduced energy consumption.

Data Point: A study published in the Journal of Food Engineering found that the use of perforated sheets in drying processes can reduce energy consumption by up to 20%, demonstrating their efficiency benefits.

Innovative Uses of Perforated Metal Sheets

The versatility of perforated metal sheets allows for innovative applications in food processing.

Smoking and Roasting

Perforated metal sheets are used in smoking and roasting processes to ensure even exposure to heat and smoke. This application is crucial for producing smoked meats, fish, and other delicacies. The perforations allow for better penetration of smoke and heat, resulting in enhanced flavor and texture.

Cheese Production

In cheese production, perforated metal sheets are used for draining whey from curds. The precise perforations ensure efficient drainage while maintaining the integrity of the curds. This application is essential for producing high-quality cheese with the desired texture and moisture content.

Beverage Filtration

Perforated metal sheets are used in the filtration of beverages such as beer, wine, and juices. The sheets provide a sturdy filtration medium that can withstand the pressures of liquid processing. The precise perforations ensure that the beverages are filtered to the desired clarity and quality.

Environmental and Economic Benefits

The use of perforated metal sheets in food processing also offers environmental and economic benefits.

Sustainability

Stainless steel perforated sheets are recyclable, contributing to sustainability efforts in the food processing industry. The ability to recycle these sheets reduces waste and conserves resources, aligning with environmental goals.

Cost-Effectiveness

The durability and longevity of perforated metal sheets result in cost savings for food processing facilities. The reduced need for frequent replacements and the efficiency gains from using these sheets lower operational costs. Additionally, the customization options allow facilities to optimize their processes, further enhancing cost-effectiveness.

Data Point: According to a report by MarketsandMarkets, the global market for stainless steel is projected to reach USD 146.5 billion by 2025, driven by its demand in various industries, including food processing.

Future Trends in Perforated Metal Sheets for Food Processing

The use of perforated metal sheets in food processing is expected to grow, driven by advancements in materials science and manufacturing technologies.

Advanced Materials

The development of advanced materials, such as high-strength alloys and composites, will expand the range of applications for perforated metal sheets in food processing. These materials offer improved performance characteristics, making them suitable for more demanding applications.

Innovative Manufacturing Techniques

Advancements in manufacturing techniques, such as precision laser cutting and additive manufacturing, will enable the production of more complex and precise perforated metal components. These innovations will enhance the design flexibility and performance of food processing equipment.

Customize Your Perforated Metal Sheets from Our Factory

Overview of the Customization Process

Our customization process ensures each perforated metal sheet meets the unique requirements of our clients:

- Consultation: Understand your specific needs and preferences through detailed consultation.

- Design: Create detailed plans based on your specifications, ensuring a perfect fit and optimal performance.

- Production: Utilize advanced manufacturing techniques to produce customized perforated metal sheets to exacting standards.

- Quality Control: Perform rigorous quality checks to ensure high standards.

- Delivery: Handle all logistics aspects to ensure timely delivery to your location.

Benefits of Custom Solutions

Customizing perforated metal sheets provides several benefits:

- Perfect Fit: Ensure a perfect fit for your facility’s equipment with custom sizes and shapes.

- Enhanced Durability: Tailored materials and designs enhance durability and performance.

- Unique Aesthetic: Match specific aesthetic requirements of your facility with custom finishes and patterns.

- Operational Efficiency: Address specific operational challenges with custom solutions, improving overall efficiency.

After-Sales Service

Reliable after-sales service ensures long-term relationships with our clients. Our after-sales service includes:

- Technical Support: Provide ongoing technical support to ensure optimal product performance.

- Maintenance Guidance: Offer detailed maintenance guides to help clients keep their perforated metal sheets in top condition.

- Replacement Parts: Provide quick access to replacement parts to minimize downtime and maintain operational efficiency.

- Customer Feedback: Actively seek and incorporate customer feedback to continually improve our products and services.

Contact Us

Enterprise customers interested in custom perforated metal sheets can contact us by submitting the form on our website. Our team stands ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and efficiency of your food processing equipment.