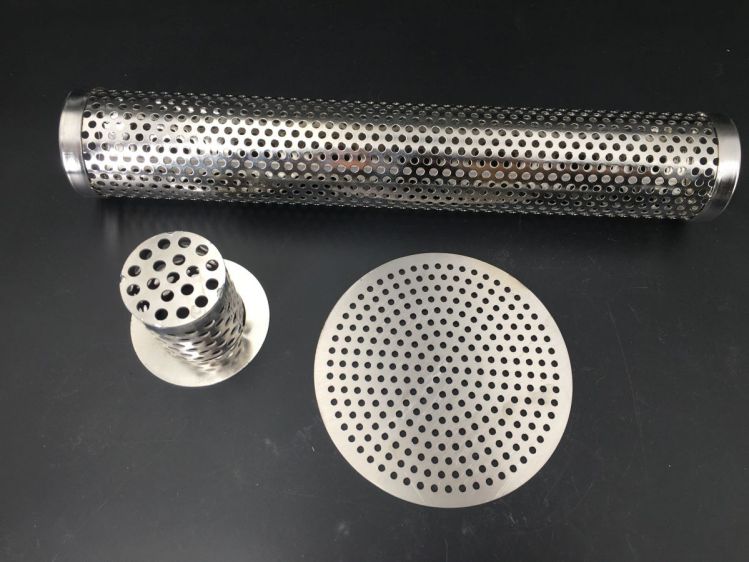

Perforated metal products, including perforated tubes, plates, and filters, are integral to various filtration processes. These components are vital in filtering liquids, air, and solids, offering numerous benefits such as durability, precision, and versatility. This article explores the applications and advantages of using perforated metal products in filtration systems.

Importance of Perforated Tubes in Filtration

Perforated tubes are essential components in many filtration systems. They are used to filter liquids, air, and solids, providing structural support and enhancing the efficiency of the filtration process.

Applications of Perforated Tubes

- Liquid Filtration: Perforated tubes are used in water treatment, chemical processing, and oil refining. They filter out contaminants and ensure the purity of the liquid.

- Air Filtration: These tubes are used in HVAC systems and industrial ventilation to remove particles from the air, ensuring a clean environment.

- Solid Filtration: In industries like mining and food processing, perforated tubes help separate solid particles from liquids and gases.

Benefits of Perforated Tubes

- High Strength: Perforated tubes provide structural support to the filtration system, ensuring durability and longevity.

- Corrosion Resistance: Made from materials like stainless steel, perforated tubes resist corrosion, making them suitable for harsh environments.

- Customizable: These tubes can be manufactured in various sizes and patterns to meet specific filtration needs.

Role of Perforated Plates in Filtration

Perforated plates are widely used in filtration systems due to their versatility and efficiency. They are used to filter liquids, air, and solids in various industrial applications.

Applications of Perforated Plates

- Liquid Filtration: Perforated plates are used in water purification, beverage production, and chemical processing to remove impurities from liquids.

- Air Filtration: In HVAC systems and industrial ventilation, perforated plates filter out dust, pollen, and other airborne particles.

- Solid Filtration: These plates are used in the food industry, mining, and pharmaceuticals to separate solid particles from liquids and gases.

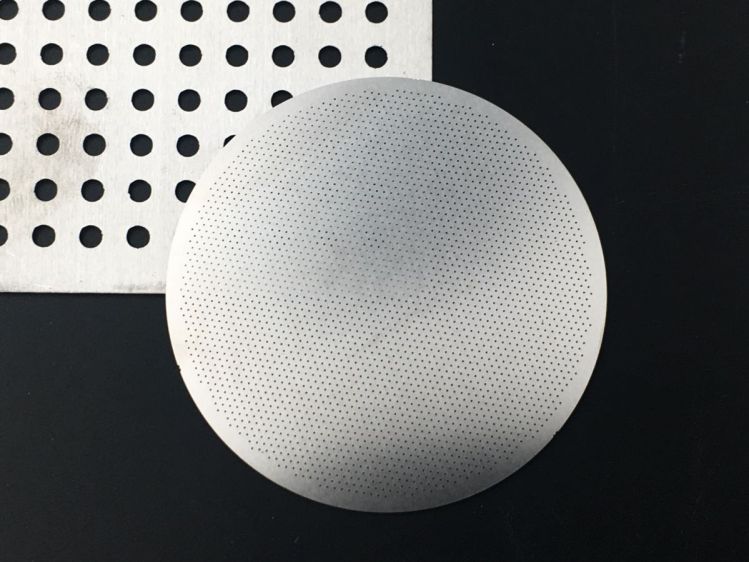

Benefits of Perforated Plates

- Precision Filtration: Perforated plates offer accurate filtration, ensuring only particles of a specific size are removed.

- Durability: Made from robust materials like stainless steel and aluminum, perforated plates withstand high pressure and temperature conditions.

- Versatility: Available in various hole sizes and patterns, perforated plates can be customized to meet specific filtration requirements.

Perforated Filters for Efficient Filtration

Perforated filters, made from perforated sheets, are crucial in various filtration applications. They filter liquids, air, and solids, ensuring the purity and quality of the filtered product.

Applications of Perforated Filters

- Liquid Filtration: Perforated filters are used in water treatment plants, oil refineries, and chemical industries to remove contaminants from liquids.

- Air Filtration: These filters are essential in HVAC systems, industrial ventilation, and air purification to eliminate dust, smoke, and other particles.

- Solid Filtration: Perforated filters are used in the food industry, pharmaceuticals, and mining to separate solid particles from liquids and gases.

Benefits of Perforated Filters

- High Filtration Precision: Perforated filters provide accurate filtration, removing particles of specific sizes from the filtered material.

- Corrosion and Temperature Resistance: Made from materials like stainless steel, these filters resist corrosion and withstand high temperatures.

- Customizable Designs: Perforated filters can be customized in terms of size, shape, and hole pattern to meet specific filtration needs.

Data on Filtration Efficiency

Studies have shown that perforated metal products significantly improve the efficiency of filtration systems. For example, in liquid filtration, perforated tubes and plates can remove up to 99% of contaminants, ensuring the purity of the filtered liquid. In air filtration, these products can filter out up to 95% of airborne particles, contributing to a cleaner environment. The high precision of perforated filters allows for the removal of particles as small as 2 microns, making them ideal for applications requiring stringent filtration standards.

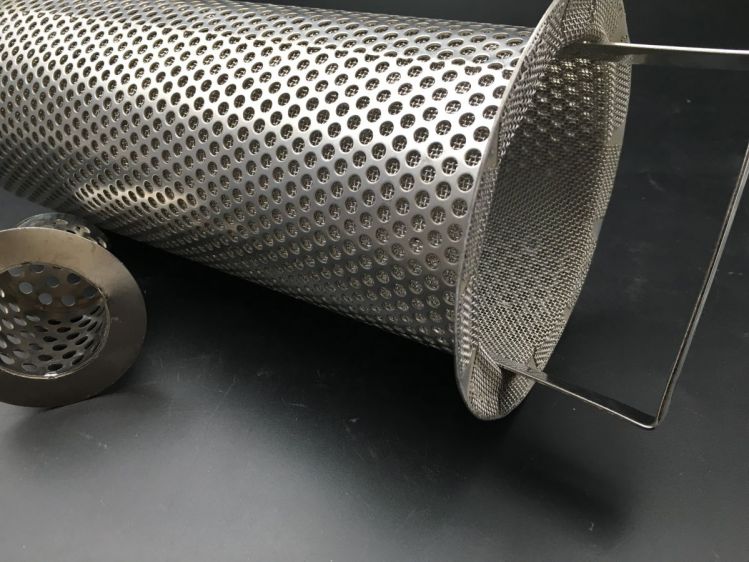

Customization Options for Perforated Metal Products

Materials and Dimensions

Perforated metal products can be customized in terms of materials and dimensions to suit specific requirements. Options include various metals like stainless steel and copper, as well as a range of thicknesses and diameters.

Perforation Patterns

Custom perforation patterns ensure that the products meet specific filtration needs. This includes variations in hole diameter and arrangement, providing tailored solutions for different applications.

Frames and Borders

Customization options also extend to frames and borders. Products can be designed with or without margins, and with different materials for wrapped edges, ensuring they fit seamlessly into existing systems.

Layers and Filters

Single or multiple layers can be used to enhance filtration precision and durability. Integrated filters can also be added to trap smaller particles, improving overall performance.

Advantages of Using Perforated Metal Products

Using perforated metal products in filtration systems offers several advantages:

- Durability: Perforated metal products are made from robust materials that can withstand harsh environments and high-pressure conditions.

- Efficiency: These products provide accurate and efficient filtration, ensuring the purity and quality of the filtered material.

- Versatility: Available in various sizes, shapes, and patterns, perforated metal products can be customized to meet specific filtration needs.

- Low Maintenance: Perforated metal products are easy to clean and maintain, reducing downtime and operational costs.

Applications in Various Industries

Perforated metal products are used in various industries due to their versatility and efficiency:

Water Treatment

In water treatment plants, perforated tubes, plates, and filters are used to remove contaminants from water, ensuring it is safe for consumption and use.

Chemical Processing

Perforated metal products are essential in chemical processing to filter out impurities and ensure the purity of chemicals and solutions.

Oil Refining

In oil refineries, perforated tubes and filters are used to remove contaminants from crude oil, ensuring the refined product is of high quality.

Food and Beverage

Perforated plates and filters are used in the food and beverage industry to ensure the purity and quality of products, such as filtering out impurities from beverages and food products.

Pharmaceuticals

In the pharmaceutical industry, perforated metal products are used to filter out impurities and ensure the purity of drugs and medical solutions.

Automotive

Perforated metal products are used in the automotive industry for filtration purposes, such as filtering out impurities from fuel and air.

Customize Your Perforated Metal Products from Our Factory

Overview of the Customization Process

Our customization process ensures each perforated metal product meets the unique requirements of our clients:

- Consultation: Understand your specific needs and preferences through detailed consultation.

- Design: Create detailed plans based on your specifications, ensuring a perfect fit and optimal performance.

- Production: Utilize advanced manufacturing techniques to produce customized perforated metal products to exacting standards.

- Quality Control: Perform rigorous quality checks to ensure high standards.

- Delivery: Handle all logistics aspects to ensure timely delivery to your location.

Benefits of Custom Solutions

Customizing perforated metal products provides several benefits:

- Perfect Fit: Ensure a perfect fit for your facility’s filtration systems with custom sizes and shapes.

- Enhanced Durability: Tailored materials and designs enhance durability and performance.

- Unique Aesthetic: Match specific aesthetic requirements of your facility with custom finishes and patterns.

- Operational Efficiency: Address specific operational challenges with custom solutions, improving overall efficiency.

After-Sales Service

Reliable after-sales service ensures long-term relationships with our clients. Our after-sales service includes:

- Technical Support: Provide ongoing technical support to ensure optimal product performance.

- Maintenance Guidance: Offer detailed maintenance guides to help clients keep their perforated metal products in top condition.

- Replacement Parts: Provide quick access to replacement parts to minimize downtime and maintain operational efficiency.

- Customer Feedback: Actively seek and incorporate customer feedback to continually improve our products and services.

Contact Us

Enterprise customers interested in custom perforated metal products can contact us by submitting the form on our website. Our team stands ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and efficiency of your filtration systems.