In the demanding environment of power plants, infrastructure durability and efficiency are paramount. Among the critical components ensuring smooth operations are floor drain covers. These covers play a vital role in maintaining hygiene and safety standards. As a leading provider of high-quality floor drain covers, we offer solutions designed to meet the rigorous demands of power plants. This article explores the application, technical benefits, specifications, design considerations, manufacturing processes, longevity, environmental impact, and customization options of our floor drain covers.

Application of Perforated Floor Drain Covers in Power Plants

Perforated floor drain covers in power plants are essential for managing water drainage, preventing debris from clogging the drainage system, and maintaining sanitary conditions. The high humidity and frequent exposure to water, chemicals, and heavy machinery necessitate robust and reliable drain covers. Stainless steel 304 perforated floor drain covers excel in these environments due to their strength, durability, and resistance to corrosion.

In power plants, these covers are used in various areas, including turbine halls, control rooms, maintenance workshops, and cooling towers. They ensure that the floors remain dry and safe, preventing slip hazards and equipment damage. Additionally, they contribute to the overall efficiency of the plant by ensuring that water and waste are effectively managed.

Technical Benefits of Floor Drain Covers

Our stainless steel 304 perforated floor drain covers offer numerous technical benefits that make them ideal for power plants:

- Corrosion Resistance: Stainless steel 304 offers excellent resistance to corrosion, making it suitable for environments exposed to moisture and chemicals.

- Durability: These covers can withstand heavy loads and impacts, ensuring long-term performance in high-traffic areas.

- Ease of Maintenance: The smooth surface of stainless steel is easy to clean, maintaining high hygiene standards with minimal effort.

- Efficient Drainage: Perforated designs ensure optimal water flow, preventing water accumulation and enhancing safety.

- Customizability: Our drain covers can be tailored to specific dimensions, perforation patterns, and finishes, ensuring they meet unique operational needs.

Technical Specifications of Floor Drain Covers

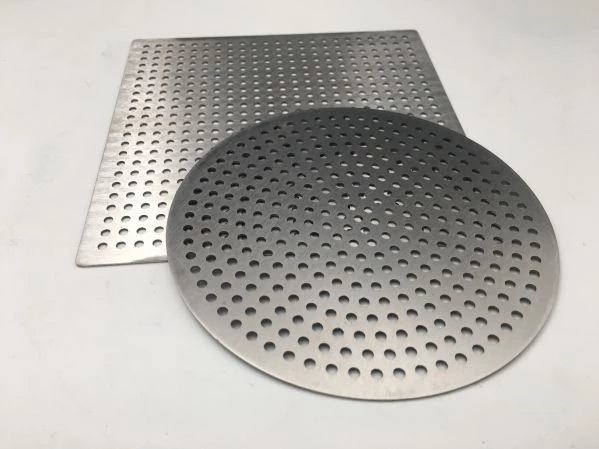

Our stainless steel 304 perforated floor drain covers come with the following technical specifications:

- Thickness: 1mm to 2mm, customizable to meet specific requirements.

- Shape: Available in round and square shapes, with options for custom shapes.

- Diameter: Ranges from 30mm to 180mm, with the possibility of customizing for non-standard sizes.

- Finish: Choose from brushed, polished, and matte finishes to suit aesthetic and functional needs.

- Perforation Patterns: Options include round holes, square holes, slotted holes, and custom patterns. For more on perforation patterns, read this article:

Optimizing Perforation Patterns for Efficient Drain Covers.

Design Considerations for Floor Drain Covers in Power Plants

Designing floor drain covers for power plants involves several critical considerations:

- Load-Bearing Capacity: The covers must support the weight of heavy machinery, maintenance equipment, and foot traffic.

- Slip Resistance: Incorporating anti-slip surfaces can enhance safety, especially in wet conditions.

- Aesthetic Integration: The design should complement the overall aesthetics of the plant while maintaining functionality.

- Accessibility: Ensuring that the drain covers are flush with the surrounding flooring prevents tripping hazards and facilitates easy cleaning.

- Ventilation and Drainage Efficiency: The perforation pattern must balance effective water drainage with debris filtration to maintain system functionality.

Manufacturing Process of Floor Drain Covers in Our Factory

Our manufacturing process for stainless steel 304 perforated floor drain covers is rigorous and precise, ensuring top-quality products:

- Material Selection: We source high-grade stainless steel 304 to ensure durability and corrosion resistance.

- Cutting and Shaping: Advanced CNC machines cut and shape the steel into the desired dimensions and forms.

- Perforation: CNC perforation creates precise and consistent patterns, enhancing drainage efficiency.

- Finishing: The covers undergo brushing, polishing, or matte finishing to achieve the desired surface texture and appearance.

- Quality Control: Rigorous inspections ensure that each cover meets our high standards for strength, durability, and performance.

Longevity of Floor Drain Covers and Our After-Sales Service

Our stainless steel 304 perforated floor drain covers are built to last. The material’s inherent corrosion resistance and strength ensure long-term performance even in demanding environments. Regular maintenance, such as cleaning and inspections, can further extend the lifespan of the covers.

We provide comprehensive after-sales services to support our clients, including:

- Maintenance Guidance: Detailed instructions on maintaining and cleaning the drain covers to preserve their condition.

- Replacement Parts: Availability of spare parts and replacement covers to ensure continuous operation.

- Customer Support: Dedicated support team to assist with any issues or queries regarding the products.

Environmental Impact and Sustainability

Stainless steel 304 is an environmentally friendly material due to its recyclability and durability. Using high-quality, long-lasting drain covers reduces the need for frequent replacements, minimizing waste. Our manufacturing processes also prioritize sustainability, with efficient resource usage and waste management practices.

Customize Your Floor Drain Covers from Our Factory

Overview of the Customization Process Offered by Our Factory

Our factory specializes in producing custom floor drain covers tailored to the specific needs of power plants. The customization process involves:

- Consultation: We work closely with clients to understand their unique requirements and challenges.

- Design: Our experts design covers that meet the specified dimensions, perforation patterns, and finishes.

- Prototyping: We create prototypes for client approval, ensuring the final product meets all expectations.

- Production: Once approved, we manufacture the covers using advanced machinery and high-quality materials.

- Quality Assurance: Each cover undergoes rigorous testing to ensure it meets our high standards for performance and durability.

Benefits of Custom Solutions Tailored to Specific Power Plants Requirements

Custom solutions offer several benefits, including:

- Perfect Fit: Custom covers ensure precise fitting, eliminating gaps and ensuring efficient drainage.

- Enhanced Performance: Tailored designs address specific operational needs, improving functionality and safety.

- Aesthetic Consistency: Custom finishes and designs match the overall aesthetic of the facility, enhancing its professional appearance.

- Special Features: Additional features such as anti-slip surfaces or reinforced structures can be incorporated to meet unique requirements.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team of experts is ready to provide tailored solutions that enhance the efficiency, safety, and aesthetics of your facility.