Efficient drainage systems are crucial in maintaining the hygiene and safety of textile factories. Floor drain covers play a vital role in ensuring smooth operations by preventing water accumulation and debris blockage. This article delves into the application, technical benefits, specifications, and design considerations of floor drain covers in textile factories. We also explore customization options and our comprehensive after-sales service.

Application of Perforated Floor Drain Covers in Textile Factories

Textile factories handle large volumes of water and chemicals daily, making effective drainage systems essential. Perforated floor drain covers are specifically designed to manage water flow and prevent clogging caused by fibers and debris. These covers ensure a clean and safe working environment by allowing water to drain efficiently while filtering out contaminants.

The robust construction of stainless steel 304 perforated floor drain covers ensures they withstand harsh industrial conditions. Their corrosion resistance makes them ideal for areas exposed to moisture and chemicals, common in textile manufacturing processes.

Technical Benefits of Floor Drain Covers

Stainless steel 304 perforated floor drain covers offer several technical benefits for textile factories:

- Corrosion Resistance: Stainless steel 304 is highly resistant to corrosion, ensuring long-term durability even in environments with frequent exposure to water and chemicals.

- High Strength: These drain covers can withstand heavy loads and impacts, making them suitable for high-traffic areas in factories.

- Hygienic Properties: Stainless steel is non-porous and easy to clean, which is essential for maintaining hygiene standards in textile production.

- Customizability: The ability to customize perforation patterns and sizes allows for optimized drainage solutions tailored to specific factory needs.

- Aesthetic Appeal: The sleek, modern look of stainless steel enhances the overall appearance of the factory floor.

Technical Specifications of Floor Drain Covers

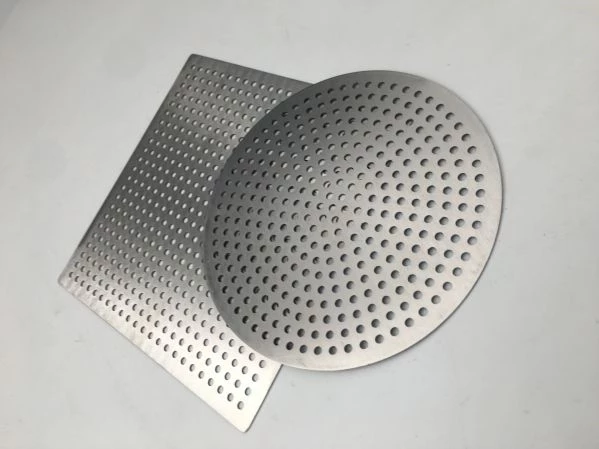

Our stainless steel 304 perforated floor drain covers are designed to meet the rigorous demands of textile factories. Key specifications include:

- Thickness: Available in 1mm to 2mm, customizable to specific requirements.

- Shape: Options include round and square shapes, with the possibility of custom shapes.

- Diameter: Ranges from 30mm to 180mm, with customization options for non-standard sizes.

- Finish: Choose from brushed, polished, or matte finishes.

- Perforation Patterns: Available patterns include round holes, square holes, slotted holes, and custom designs. For more information on optimizing perforation patterns, read Optimizing Perforation Patterns for Efficient Drain Covers.

Design Considerations for Floor Drain Covers in Textile Factories

When designing floor drain covers for textile factories, several factors must be considered to ensure optimal performance and durability:

- Load-Bearing Capacity: The covers must withstand heavy machinery and high foot traffic without deforming or breaking.

- Corrosion Resistance: Given the frequent exposure to water and chemicals, choosing a corrosion-resistant material like stainless steel 304 is crucial.

- Ease of Cleaning: The design should facilitate easy cleaning to maintain hygiene and prevent blockages.

- Perforation Size and Pattern: The perforations must be small enough to filter out fibers and debris but large enough to allow efficient water flow.

- Installation Ease: The covers should be easy to install and remove for maintenance purposes.

Enhancing Drainage Efficiency with Custom Perforation Patterns

Custom perforation patterns can significantly enhance the drainage efficiency of floor drain covers. By tailoring the size and arrangement of the perforations, you can optimize water flow and debris filtration to meet specific needs. For example, textile factories may require finer perforations to capture smaller fibers and prevent clogging. Our factory offers a variety of custom patterns to ensure the best performance for your unique requirements.

The Role of Floor Drain Covers in Workplace Safety

Floor drain covers contribute to workplace safety by preventing water accumulation and reducing the risk of slips and falls. In textile factories, where spills and leaks are common, having efficient drainage is critical. Properly designed and installed drain covers ensure that water is quickly drained away, maintaining a dry and safe working environment. Additionally, using high-strength materials like stainless steel 304 ensures that the covers can handle heavy loads and impacts, further enhancing safety.

After-Sales Service

We prioritize customer satisfaction by offering comprehensive after-sales service for our floor drain covers. Our services include:

- Technical Support: Our experts provide ongoing technical support to ensure optimal product performance.

- Maintenance Guidance: We offer detailed maintenance guides to help you keep your floor drain covers in top condition.

- Replacement Parts: We provide quick access to replacement parts to minimize downtime and maintain operational efficiency.

- Customer Feedback: We actively seek and incorporate customer feedback to continually improve our products and services.

Customize Your Floor Drain Covers from Our Factory

Overview of the Customization Process

Our customization process ensures that your floor drain covers meet the specific requirements of your textile factory. Here’s an overview:

- Consultation: We begin with a thorough consultation to understand your needs and preferences.

- Design: Our design team creates detailed plans based on your specifications.

- Production: Using advanced manufacturing techniques, we produce the customized floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

Benefits of Custom Solutions Tailored to Export

Customizing floor drain covers for export offers several benefits:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance the durability and performance of the covers.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team is ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.