Public restrooms face unique challenges that demand robust and efficient drainage solutions. White label floor drain covers provide a perfect blend of functionality, durability, and customization, meeting the specific requirements of public facilities. This article explores the application, technical specifications, design considerations, and manufacturing processes of our white label floor drain covers. Additionally, we will discuss the benefits of customization and our comprehensive after-sales service.

Application of Perforated Floor Drain Covers in Public Restrooms

Perforated floor drain covers are essential in public restrooms to manage water efficiently and maintain hygiene standards. They prevent water accumulation, reduce slip hazards, and ensure a clean environment. Key applications include:

- High Traffic Areas: Ensuring efficient drainage in busy public restrooms.

- Shower Areas: Facilitating quick water flow and preventing pooling in communal shower facilities.

- Hand Wash Areas: Managing wastewater from multiple sinks to avoid flooding.

- Entry Points: Capturing debris and preventing clogging at restroom entrances.

Technical Specifications of Floor Drain Covers

Our floor drain covers are engineered to meet the stringent demands of public restrooms. Key technical specifications include:

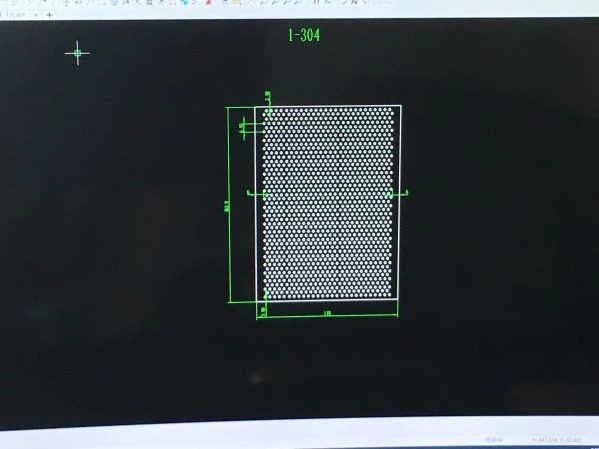

- Thickness: 1mm to 2mm, customizable to specific requirements.

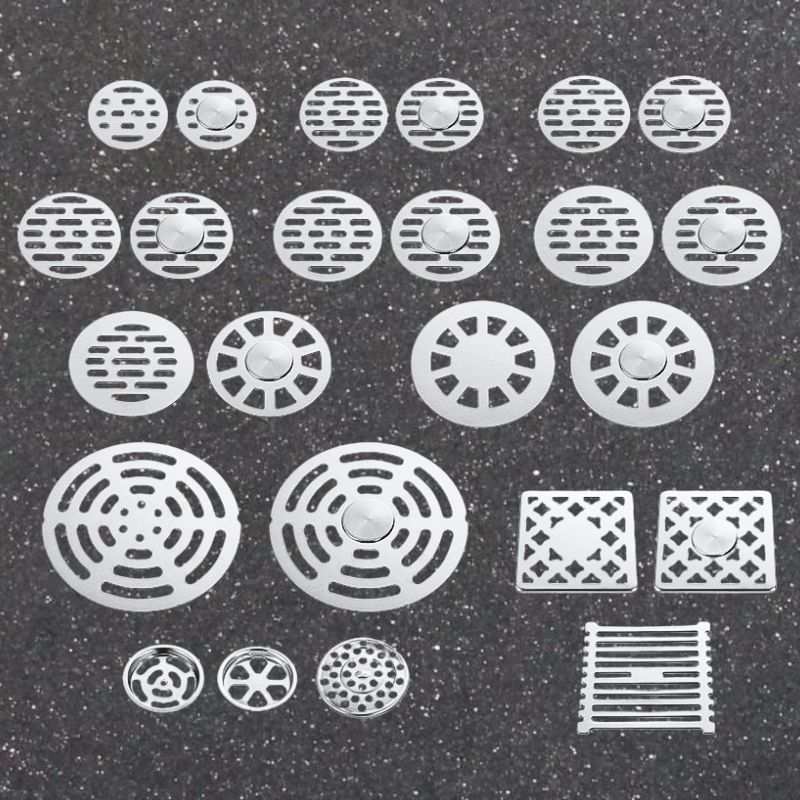

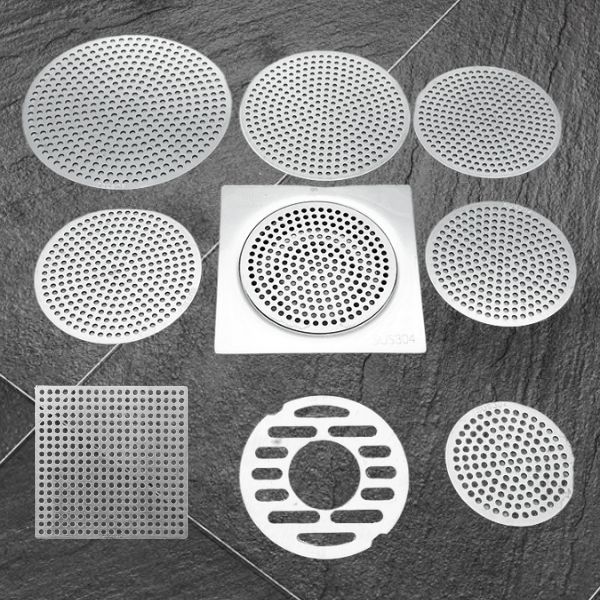

- Shape: Available in round and square shapes, with custom shapes also available.

- Diameter: Ranges from 30mm to 180mm, with options for non-standard sizes.

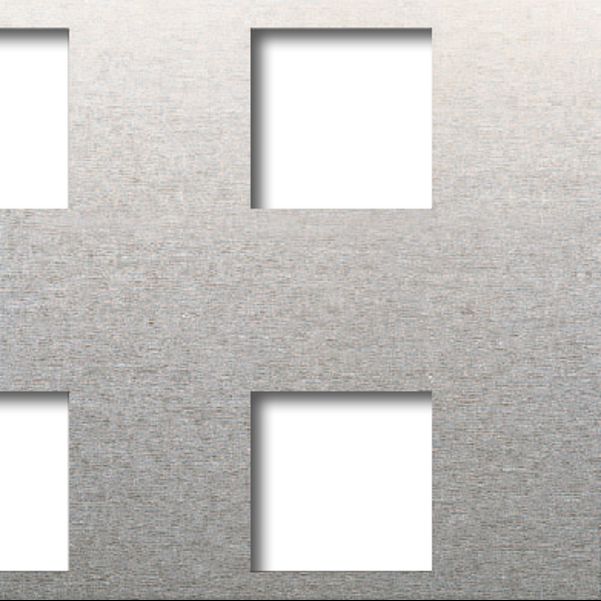

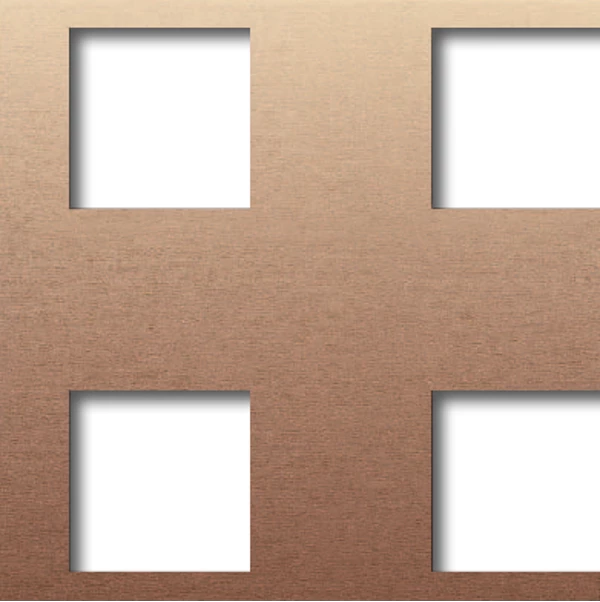

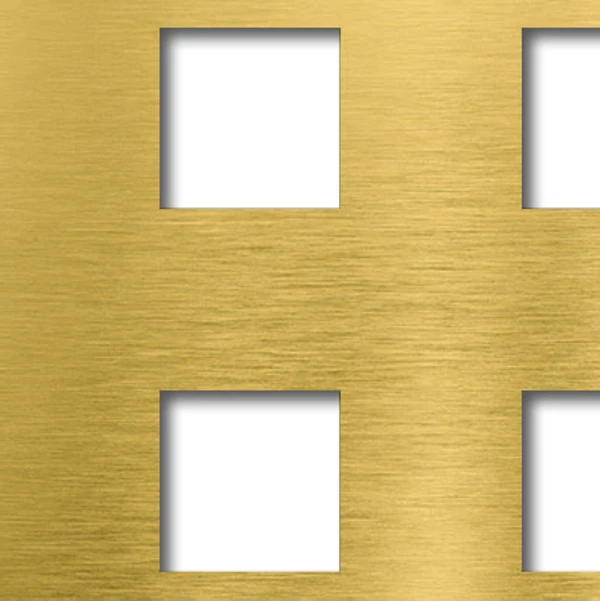

- Finish: Choose from brushed, polished, or matte finishes to suit your facility’s aesthetics.

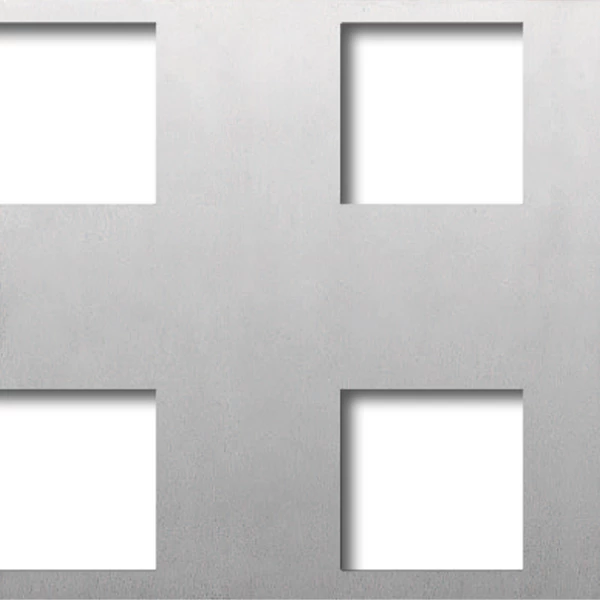

- Perforation Patterns: Options include round holes, square holes, slotted holes, and custom patterns. For more details on optimizing perforation patterns, read this article:

Optimizing Perforation Patterns for Efficient Drain Covers.

These specifications ensure that our floor drain covers provide superior performance and durability in public restroom settings.

Design Considerations for Floor Drain Covers in Public Restrooms

Designing floor drain covers for public restrooms involves several critical considerations to ensure they meet functional and aesthetic requirements. Key factors include:

- Load Capacity: Ensuring the drain covers can withstand heavy foot traffic and potential impacts from cleaning equipment.

- Corrosion Resistance: Using stainless steel 304 to resist corrosion from water and cleaning chemicals.

- Ease of Cleaning: Designing perforation patterns that are easy to clean and maintain.

- Aesthetic Integration: Matching the drain covers with the restroom’s overall design for a seamless look.

- Safety Features: Incorporating anti-slip surfaces to prevent accidents in wet conditions.

White Label Floor Drain Covers: Brand Customization

White label floor drain covers offer enterprises the flexibility to brand and market these products under their own names. This customization includes:

- Logo Integration: Adding your company’s logo to the drain covers for brand visibility.

- Custom Packaging: Designing packaging that reflects your brand’s identity and meets market standards.

- Product Differentiation: Customizing features to meet specific market demands, enhancing product appeal.

White Label Floor Drain Covers: Market Expansion

White label solutions enable enterprises to expand their product offerings without the need for in-house manufacturing. Benefits include:

- Cost Efficiency: Reducing costs associated with manufacturing and product development.

- Speed to Market: Accelerating the launch of new products by leveraging existing manufacturing capabilities.

- Quality Assurance: Ensuring high-quality products through established manufacturing processes and standards.

- Market Adaptability: Quickly adapting to market changes with customizable features and designs.

Manufacturing Process of Floor Drain Covers in Our Factory

Our manufacturing process ensures the highest quality standards for our white label floor drain covers. The process includes:

- Material Selection: We use premium stainless steel 304 for its durability and corrosion resistance.

- Cutting and Shaping: Advanced CNC machines cut and shape the stainless steel sheets to precise dimensions.

- Perforation: Custom perforation patterns are created using state-of-the-art machinery to meet specific drainage requirements.

- Finishing: Covers are finished to the desired texture, whether brushed, polished, or matte.

- Quality Control: Each cover undergoes rigorous quality checks to ensure it meets our high standards.

- Packaging: Custom packaging solutions are provided for white label clients, ensuring the product is ready for retail.

After-Sales Service

We provide comprehensive after-sales service to ensure our products continue to perform optimally. Our services include:

- Technical Support: Our team offers ongoing technical support for any issues or questions that arise.

- Maintenance Tips: We provide detailed maintenance guides to help keep the drain covers in top condition.

- Replacement Parts: Quick access to replacement parts ensures minimal downtime.

- Customer Feedback: We actively seek feedback to continuously improve our products and services.

Customize Your Floor Drain Covers from Our Factory

Overview of the Customization Process

Our customization process is designed to meet the specific needs of public restrooms. Here’s how it works:

- Consultation: We begin with a thorough consultation to understand your requirements.

- Design: Our design team creates detailed plans based on your specifications.

- Production: Using advanced manufacturing techniques, we produce customized floor drain covers.

- Quality Control: Each product undergoes rigorous quality checks.

- Delivery: We handle all aspects of logistics to ensure timely delivery.

Benefits of Custom Solutions Tailored to Specific Public Restroom Requirements

Customizing floor drain covers for public restrooms offers several benefits:

- Perfect Fit: Ensuring covers fit precisely to prevent water leakage and maximize drainage efficiency.

- Enhanced Durability: Using materials and designs tailored to withstand high traffic and cleaning routines.

- Aesthetic Matching: Custom finishes and patterns to complement restroom design.

- Improved Safety: Features like anti-slip surfaces to enhance user safety.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team is ready to assist with your specific needs and provide tailored solutions that enhance the functionality and appearance of your public restrooms.