White Label Floor Drain Covers for Industrial Applications

Floor drain covers play a critical role in maintaining cleanliness, safety, and efficiency in industrial environments. White label floor drain covers offer a customizable solution that meets the unique needs of various industrial applications. This article explores the design and technical aspects of white label floor drain covers, their benefits, materials used, customization options, and after-sales service.

Importance of White Label Floor Drain Covers

White label floor drain covers provide significant advantages for industrial applications. They offer the flexibility to brand the products under your company’s name, enhancing brand recognition and loyalty. These covers ensure optimal drainage, prevent debris clogging, and maintain sanitary conditions, which are crucial in industries like manufacturing, food processing, and chemical production. By choosing white label options, businesses can maintain high standards of quality and consistency while tailoring the products to their specific needs.

Key Benefits of White Label Floor Drain Covers

The benefits of white label floor drain covers include:

- Brand Customization: Businesses can rebrand these covers to align with their corporate identity, ensuring consistency across all facilities.

- Cost-Effectiveness: Bulk purchasing and customization can lead to significant cost savings.

- High Quality: These covers meet stringent quality standards, ensuring durability and performance in demanding industrial environments.

- Flexibility: Customizable designs and materials allow businesses to choose the best solutions for their specific applications.

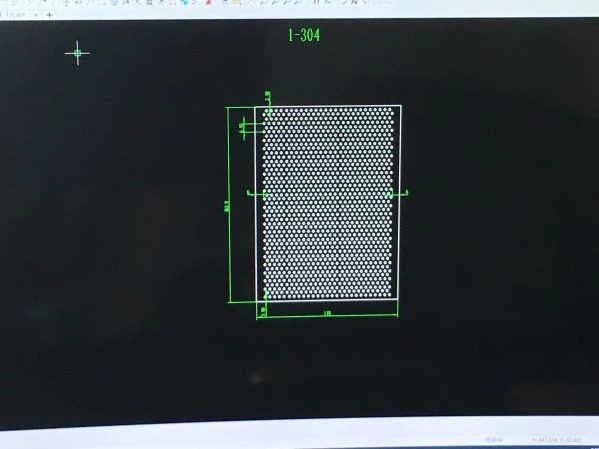

Specifications and Design Options

Our white label floor drain covers come with a range of specifications and design options to suit various industrial needs:

- Thickness: Available in 1mm to 2mm, customizable to specific requirements.

- Shape: Round and square shapes are standard, with custom shapes available upon request.

- Diameter: Ranges from 30mm to 180mm, with options for non-standard sizes.

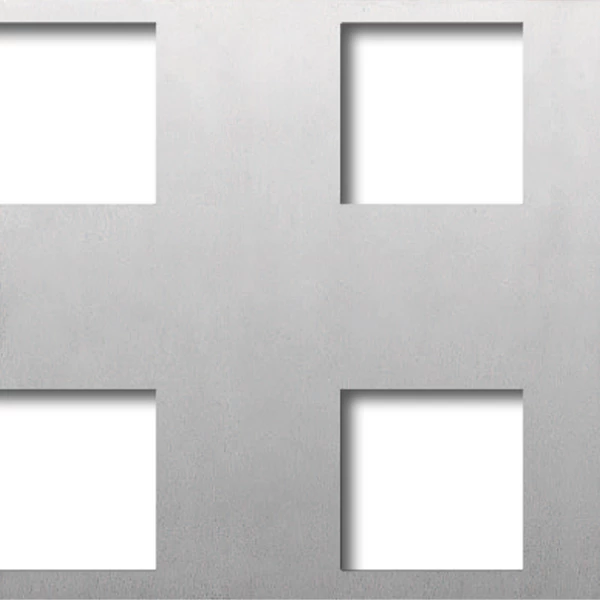

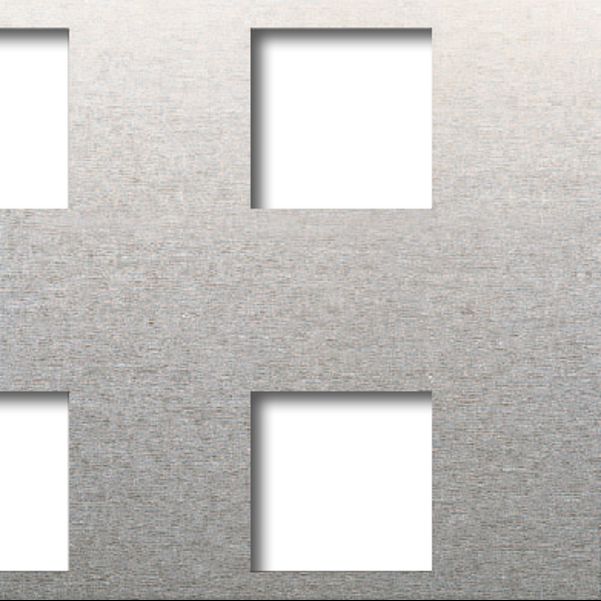

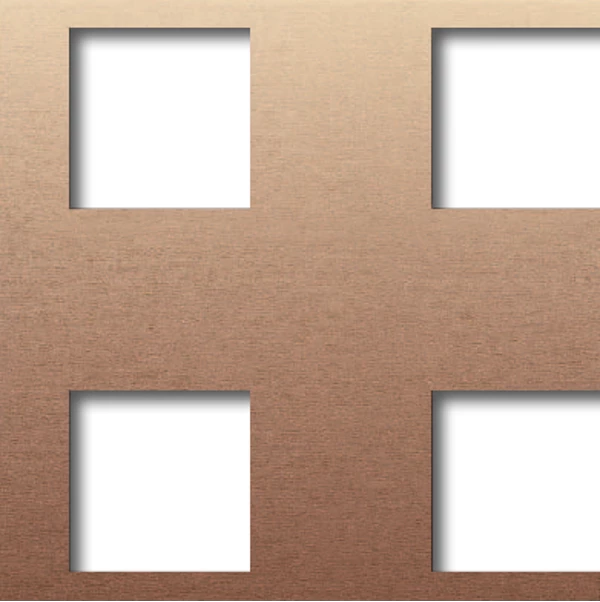

- Finish: Options include brushed, polished, and matte finishes.

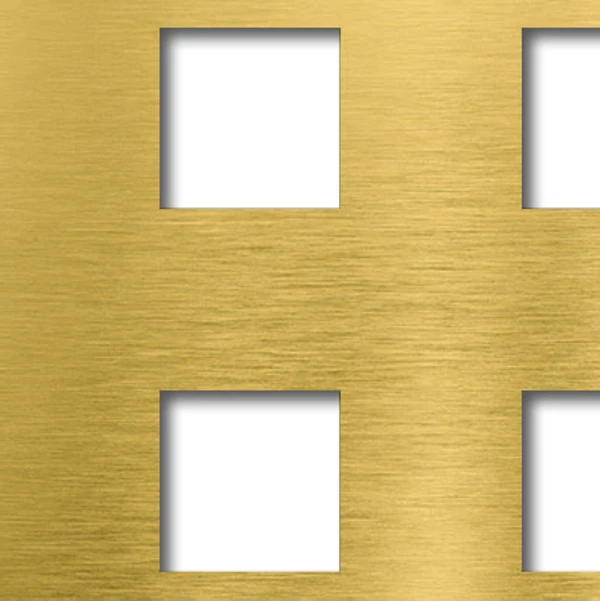

- Perforation Patterns: Choose from round holes, square holes, slotted holes, or custom patterns. For more details on optimizing perforation patterns, read this article Optimizing Perforation Patterns for Efficient Drain Covers.

Materials Used in White Label Floor Drain Covers

We use high-quality materials to ensure the durability and performance of our floor drain covers:

- Stainless Steel 304: Known for its excellent corrosion resistance and durability, ideal for environments exposed to moisture and chemicals.

- Stainless Steel 316: Offers superior corrosion resistance, particularly in marine and harsh chemical environments.

- Other Materials: We also offer options in other stainless steel grades and custom alloys to meet specific industrial requirements.

Customization Process

Our customization process ensures that your white label floor drain covers meet all your specific needs:

- Consultation: We begin with a detailed consultation to understand your requirements and preferences.

- Design: Our design team creates detailed plans based on your specifications, including custom shapes, sizes, and finishes.

- Prototype: We develop a prototype for your approval, ensuring it meets all design and functional requirements.

- Production: Using advanced manufacturing techniques, we produce the customized floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

Installation Techniques

Proper installation of floor drain covers is crucial for their performance and longevity. Key steps include:

- Site Assessment: Evaluate the drainage requirements and select appropriate cover types and materials.

- Preparation: Clean the area around the drain to ensure a secure fit. Remove any debris or old covers.

- Measurement: Measure the drain opening accurately to choose the correct size cover. Ensure the cover fits snugly without gaps.

- Installation: Place the cover over the drain, aligning it correctly. Secure it using screws or locking mechanisms, if applicable.

- Testing: Pour water to test the drainage efficiency and check for any leaks or misalignment.

Maintenance Tips

Regular maintenance ensures that your white label floor drain covers remain functional and efficient:

- Cleaning: Regularly remove debris and clean the covers to prevent clogging. Use appropriate cleaning agents to maintain the stainless steel’s shine and hygiene.

- Inspection: Conduct periodic inspections to check for damage or wear. Replace covers that show signs of corrosion, cracks, or significant wear.

- Lubrication: Apply lubricants to moving parts and screws to prevent rust and ensure easy removal for cleaning.

- Record Keeping: Maintain a log of inspections and maintenance activities to track the condition of the drain covers and schedule timely replacements.

Customize Your White Label Floor Drain Covers from Our Factory

Overview of the Customization Process

Our customization process is designed to provide tailored solutions that meet the specific requirements of our clients. Here’s an overview of the process:

- Consultation: We begin with a thorough consultation to understand your needs and preferences.

- Design: Our design team creates detailed plans based on your specifications.

- Production: Using advanced manufacturing techniques, we produce the customized floor drain covers to exacting standards.

- Quality Control: Each product undergoes rigorous quality checks to ensure it meets our high standards.

- Delivery: We handle all aspects of logistics to ensure timely delivery to your location.

Benefits of Custom Solutions Tailored to Export

Customizing floor drain covers for export offers several benefits:

- Perfect Fit: Custom sizes and shapes ensure a perfect fit for your facility’s drainage systems.

- Enhanced Durability: Tailored materials and designs enhance the durability and performance of the covers.

- Unique Aesthetic: Custom finishes and patterns can match the specific aesthetic requirements of your facility.

- Operational Efficiency: Custom solutions address specific operational challenges, improving overall efficiency.

After-Sales Service

We provide comprehensive after-sales service to ensure customer satisfaction:

- Technical Support: Our team of experts provides ongoing technical support to ensure optimal product performance.

- Maintenance Guidance: We offer detailed maintenance guides to help clients keep their floor drain covers in top condition.

- Replacement Parts: We provide quick access to replacement parts to minimize downtime and maintain operational efficiency.

- Customer Feedback: We actively seek and incorporate customer feedback to continually improve our products and services.

Contact Us

Enterprise customers interested in custom floor drain covers can contact us by submitting the form on our website. Our team is ready to assist you with your specific needs and provide tailored solutions that enhance the functionality and appearance of your facility.